Residual current circuit breaker

A leakage circuit breaker and circuit technology, which is applied in the direction of circuit devices, emergency protection circuit devices, electrical components, etc., can solve the problems of enlarged test circuit installation space, increased test circuit installation space, and increased manufacturing costs, achieving accurate and Effects of stable leakage test, accurate and stable operation test, and reduced installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

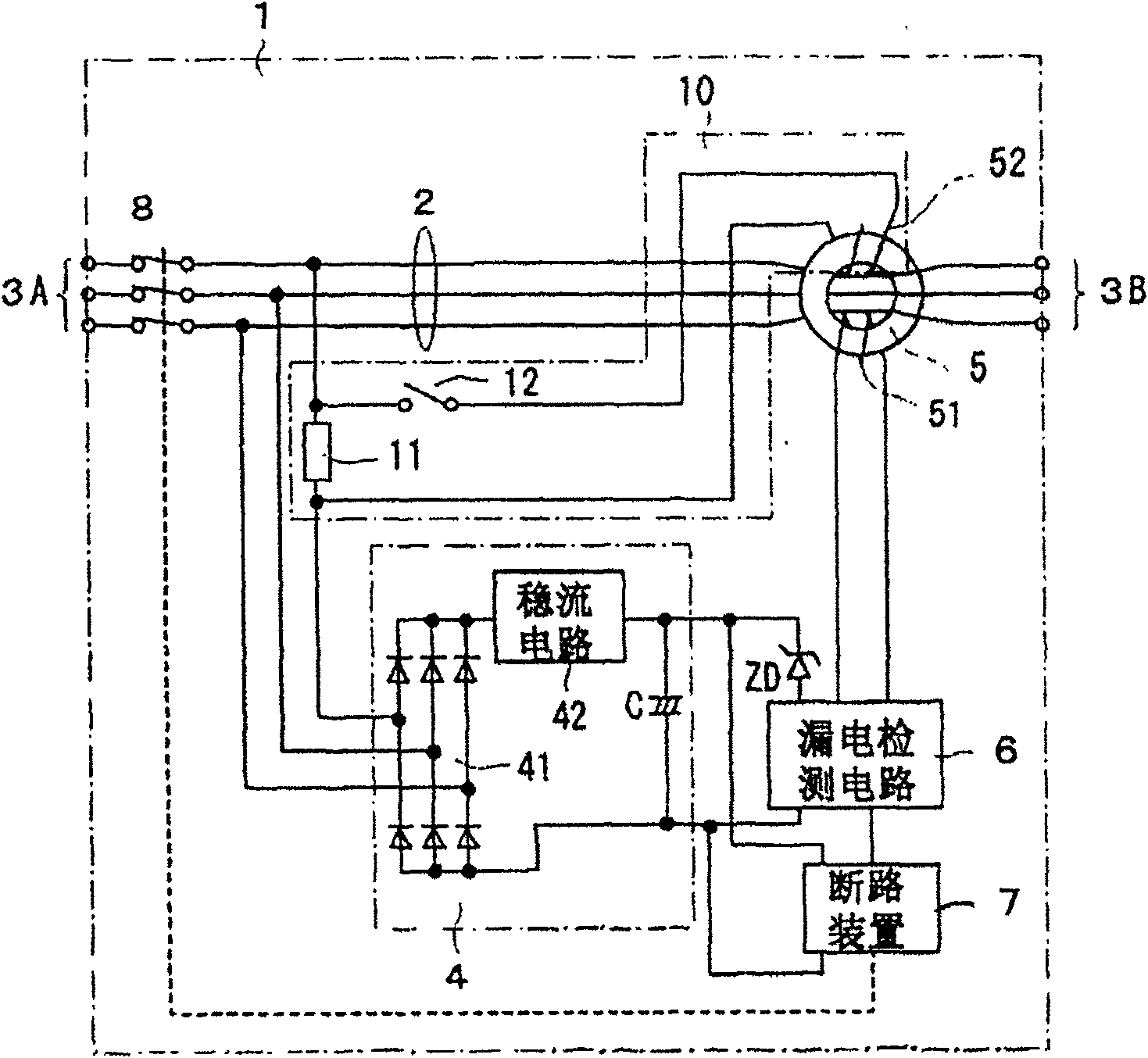

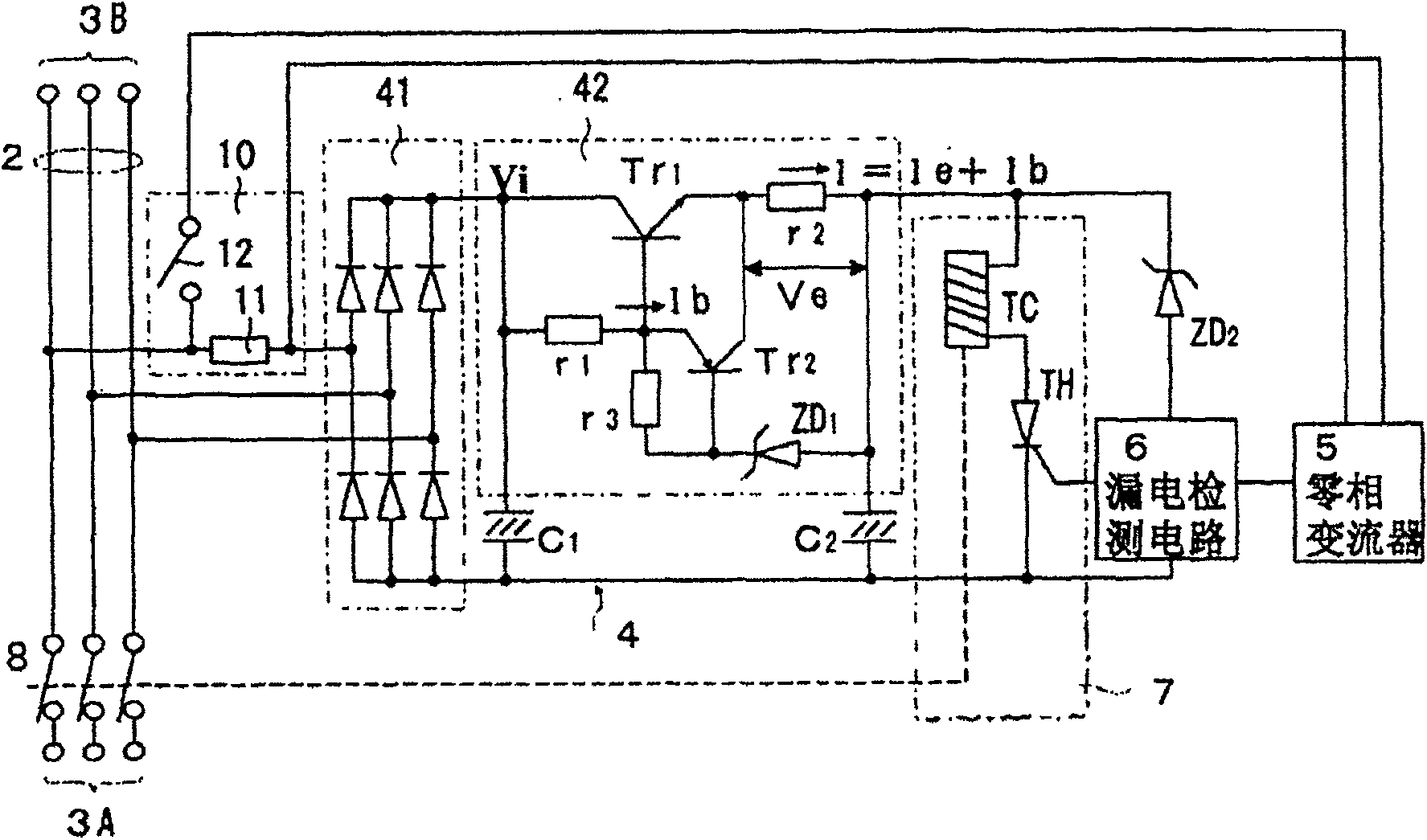

[0032] figure 1 It is a structural diagram showing Example 1 of the present invention.

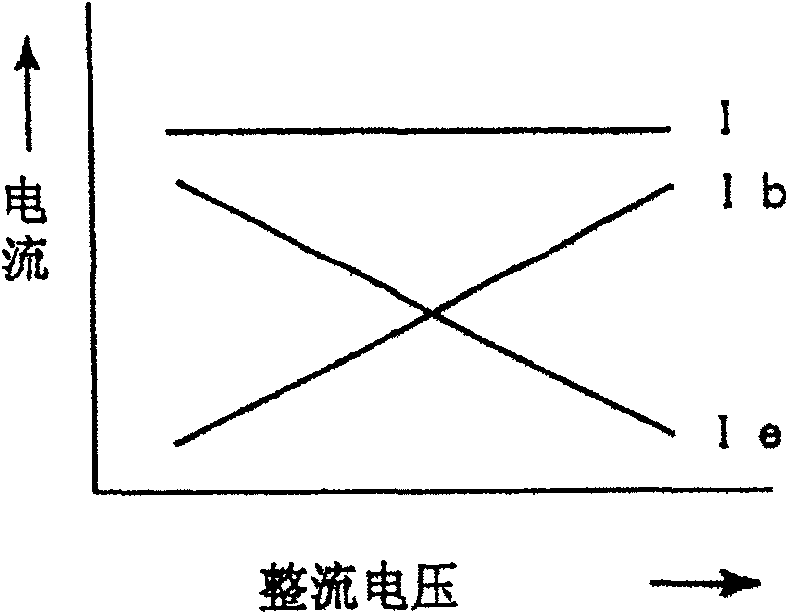

[0033] in figure 1 Among them, 1 is a leakage circuit breaker, and usually all the structural elements are housed in a molded case made of insulating resin and formed compactly. The earth leakage circuit breaker 1 is equipped with: the main circuit 2 connecting the power supply side connection terminal 3A and the load side connection terminal 3B; the opening and closing section 8 that makes the main circuit 2 on and off; The zero-phase converter 5 of the leakage current flowing through the main circuit; the leakage detection circuit 6 that monitors the detection current of the leakage detection coil 51 of the zero-phase converter 5 and judges whether there is a leakage; according to the leakage detection circuit 6 An output signal indicating a leakage, a circuit breaker 7 that interrupts the on-off mechanism of the opening and closing section 8 to open the opening and closing section; and a...

Embodiment 2

[0045] Secondly, Figure 4 The structure of Embodiment 2 of the present invention is shown in.

[0046] This embodiment 2 is different from embodiment 1 only in the input resistance R 1 , R 2 And R 3 In each phase connected to the AC input side of the rectifier circuit 41 of the power supply circuit 4, the other structures are the same.

[0047] In this way, if the input resistance R 1 , R 2 , R 3 Connected to the power supply circuit 4, these resistance elements and the smoothing capacitor C in the power supply circuit 4 can be used 1 (Reference figure 2 ) Form a filter circuit, so it can absorb high frequency surge voltage, and therefore can improve the surge voltage withstand voltage of the power supply circuit 4 and the test switch 12 of the test circuit 10.

Embodiment 3

[0049] Figure 5 It is a block diagram showing Embodiment 3 of the present invention.

[0050] The Figure 5 Example 3 shown is to combine two Zener diodes ZD 3 And ZD 4 It is an embodiment in which the reverse series connection is connected to both ends of the test resistance element 11, and the terminal voltage of the test resistance element 11 is limited below a certain voltage determined by the Zener diode. Even without reducing the resistance value of the test resistance element 11, by installing a Zener diode, the voltage at both ends can be limited below a certain value, and the burden of the AC voltage of the test switch 12 can be reduced, so the contacts can be spaced apart Narrower, the overall size of the switch can be miniaturized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com