Vortex diode

A diode, eddy current technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of blockage, leakage of sealing material, wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

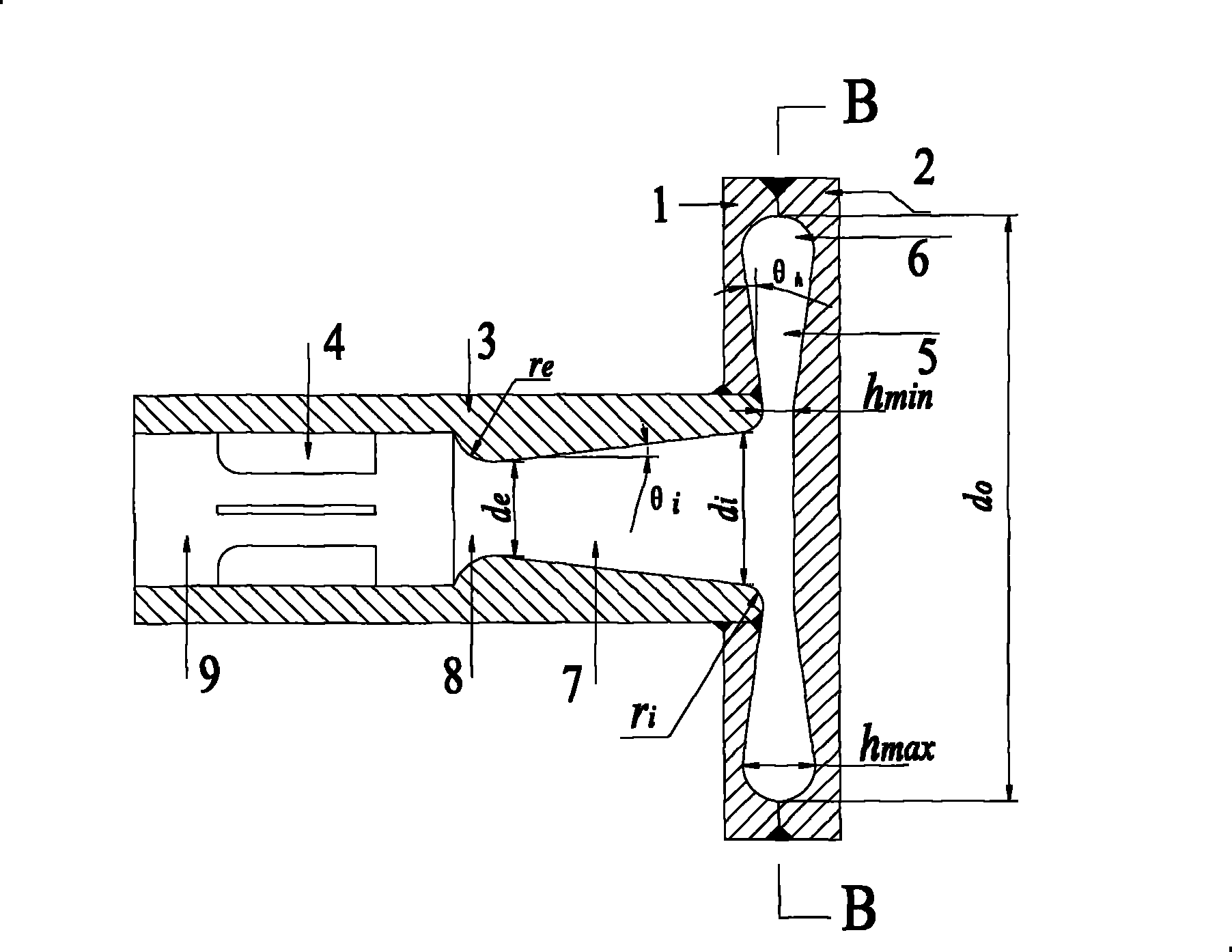

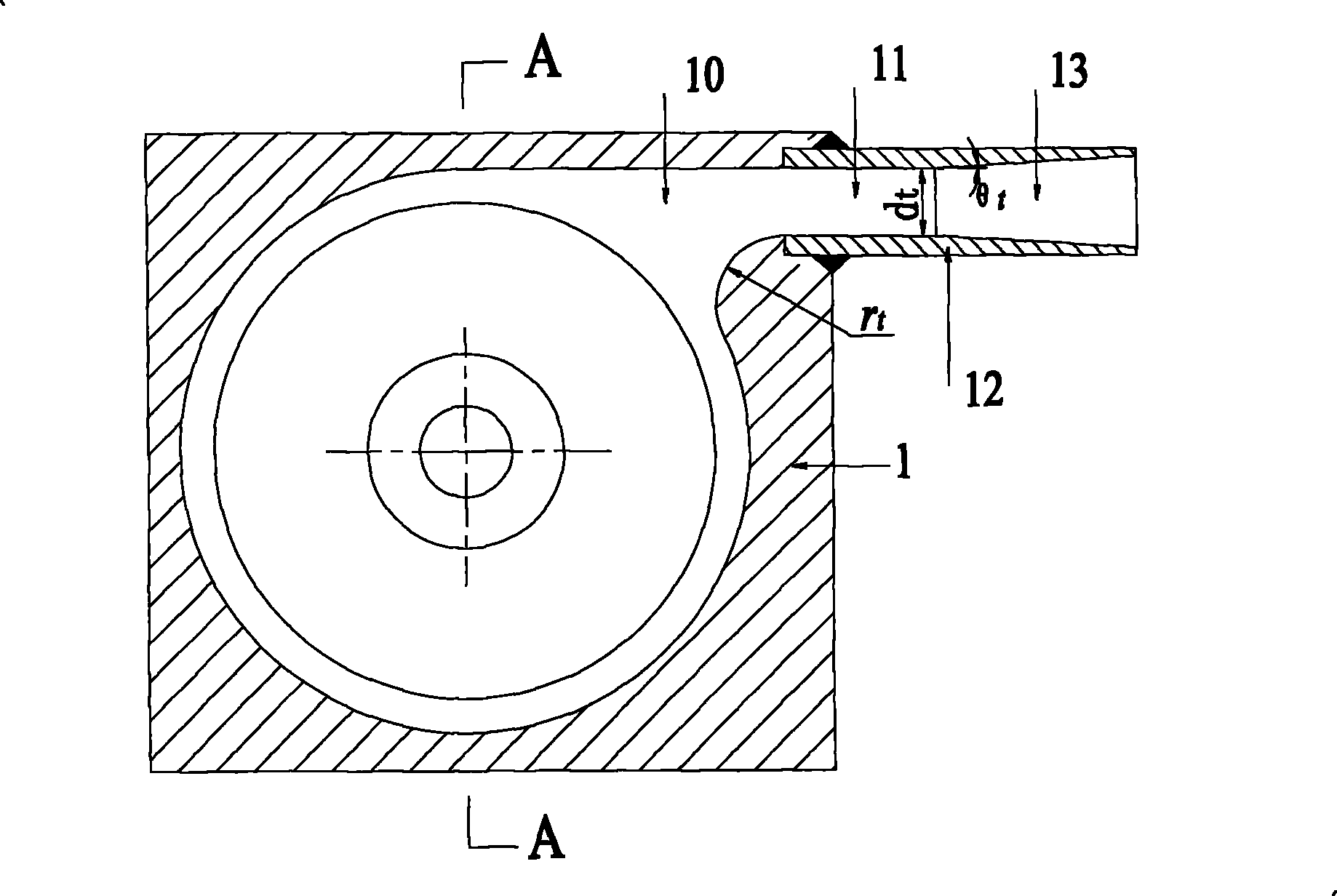

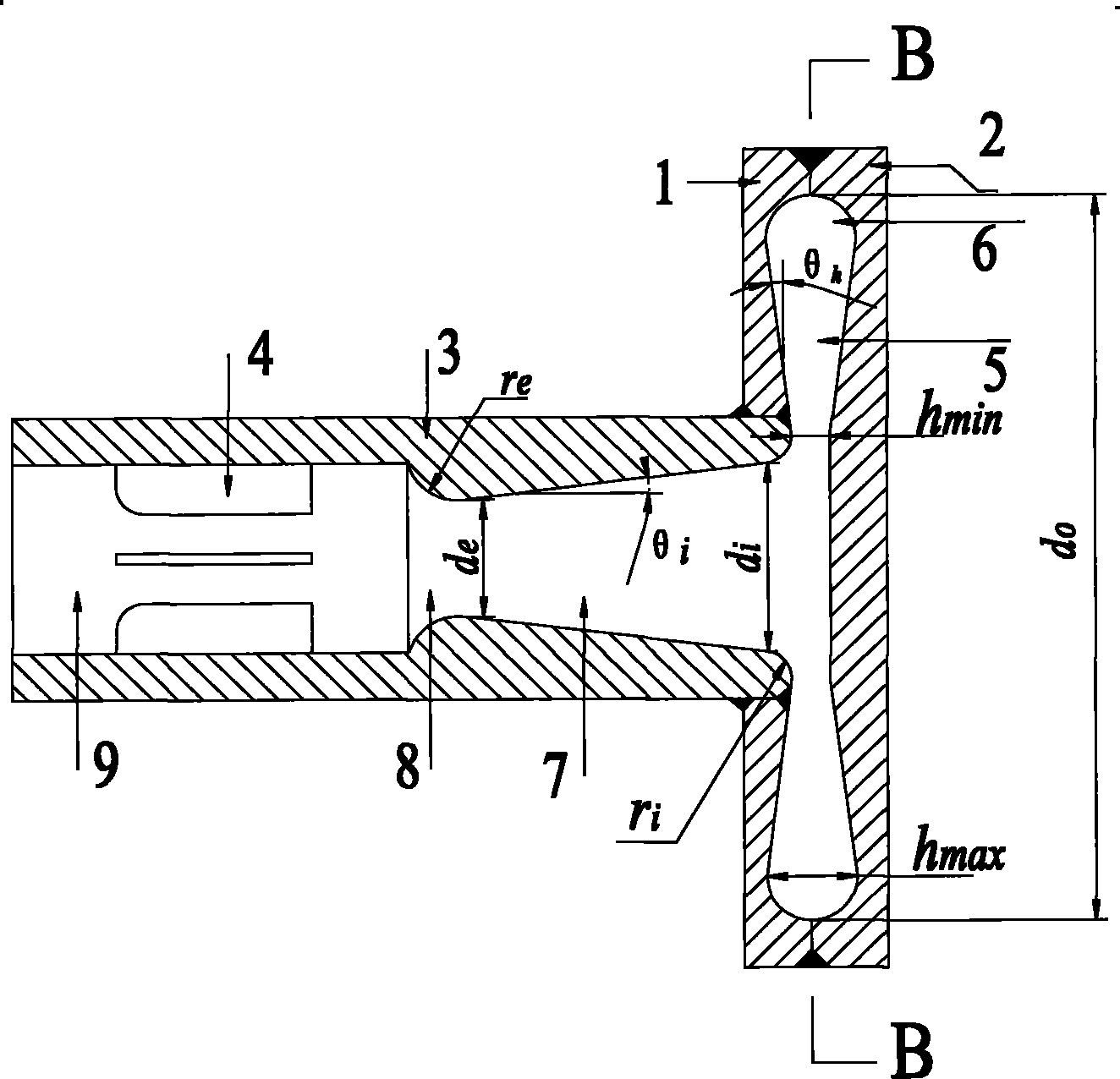

[0019] Such as figure 1 , 2 As shown, the eddy current diode includes an upper cover plate 1, a lower cover plate 2, a central tube shell 3, a guide vane 4, a vortex chamber 5, a semicircular side wall 6, a central cone tube 7, an arc shrink tube 8, and a central straight tube 9 , arc transition area 10, tangential pipe shell 12, tangential tapered pipe 13; center pipe shell 3 is divided into central tapered pipe 7, arc shrinkage pipe 8, central straight pipe 9, center pipe from bottom to top The lower end of the casing 3 is provided with an upper cover plate 1, the upper cover plate 1 is connected with the lower cover plate 2 to form a vortex chamber 5, the central straight pipe 9 is provided with a guide vane 4, and a tangential pipe casing is provided in the tangential direction of the circumference of the vortex chamber 5 12. The tangential tube housing 12 is divided into a tangential straight tube 11 and a tangential conical tube 13 from inside to outside. The junction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com