Construction method for erecting steel truss girder on uplift pushing tow

A construction method and technology of steel truss girders, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of large deflection of steel truss girders, large internal stress of steel truss girders, etc., and achieve reliable fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be described as an example below, and the protection scope of the present invention is not specifically limited.

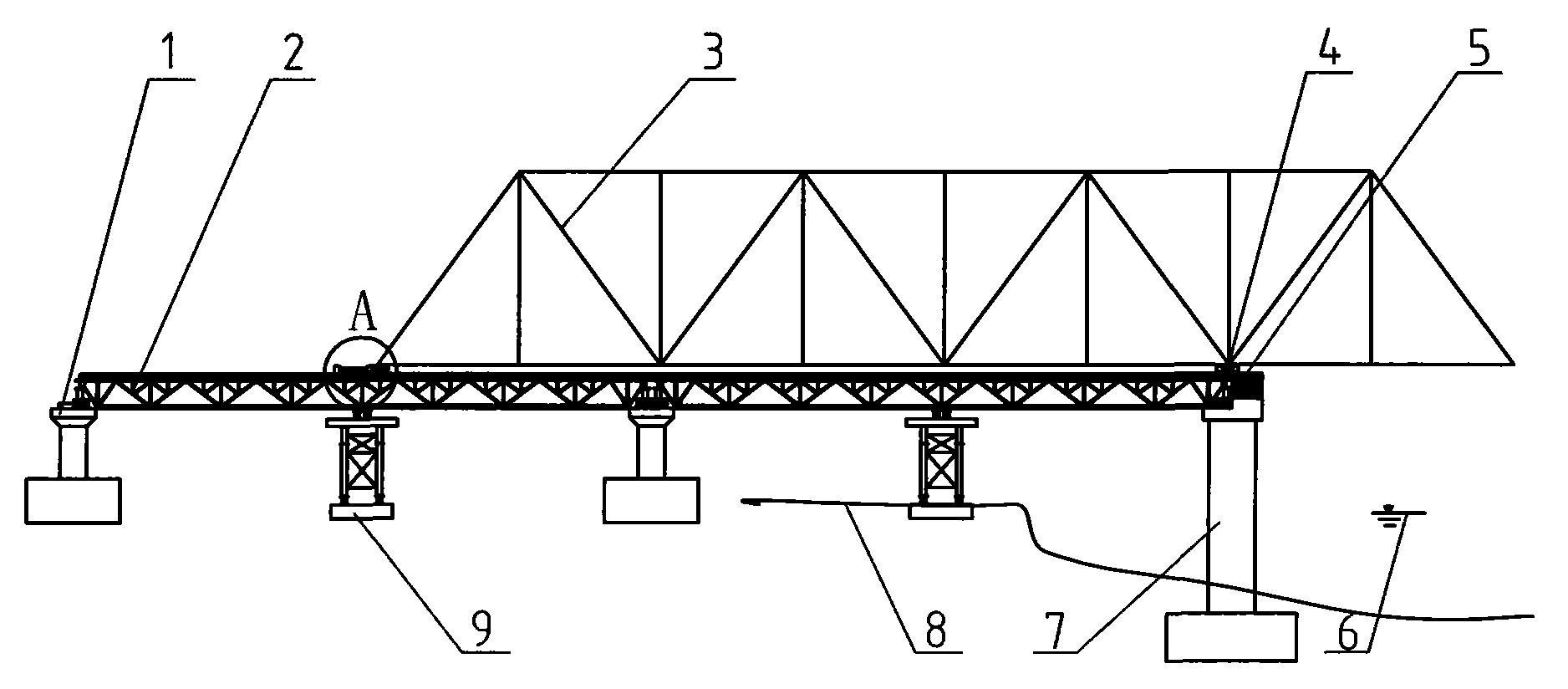

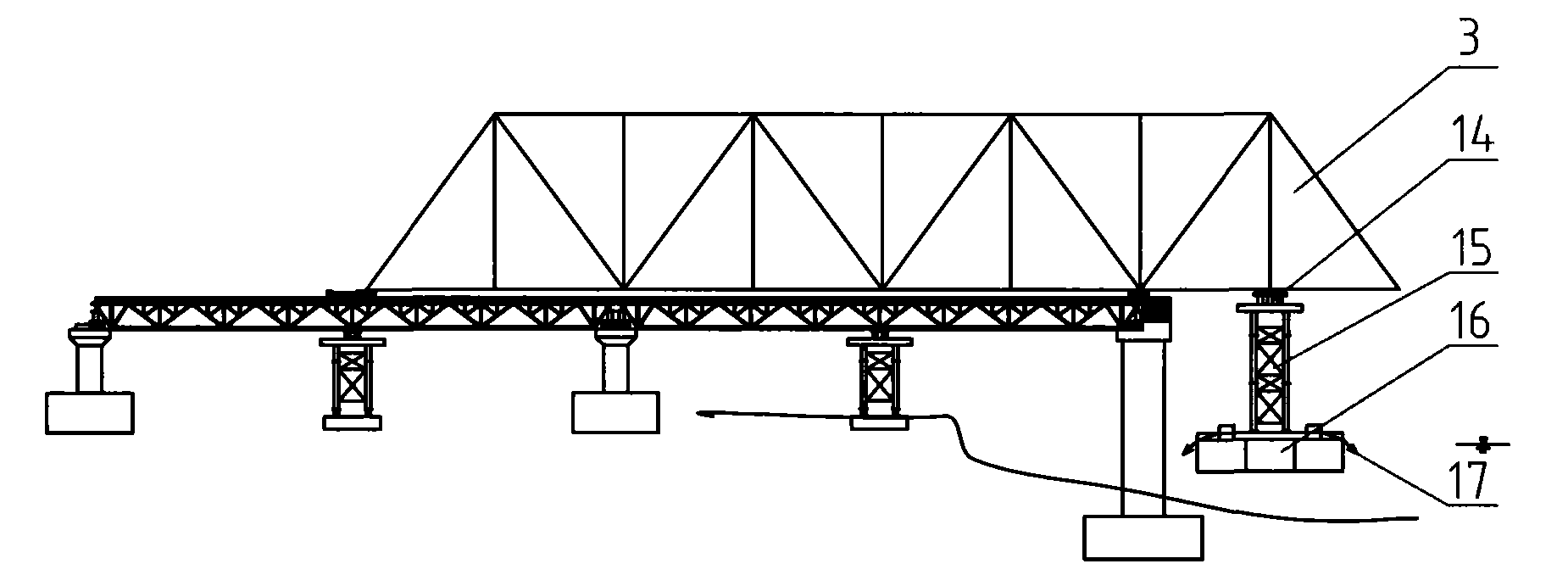

[0040] Refer to the attached Figures 1 to 4 , a construction method for erecting steel truss girders by means of floating supports and pushing, comprising the following steps:

[0041] 1) a. Erecting frame, the pier 1 along the bank uses the standard military girder as the construction convenience beam 2 to the first main pier 7 located in the waterline 6, as a platform for the steel truss girder 3 to be assembled and pushed;

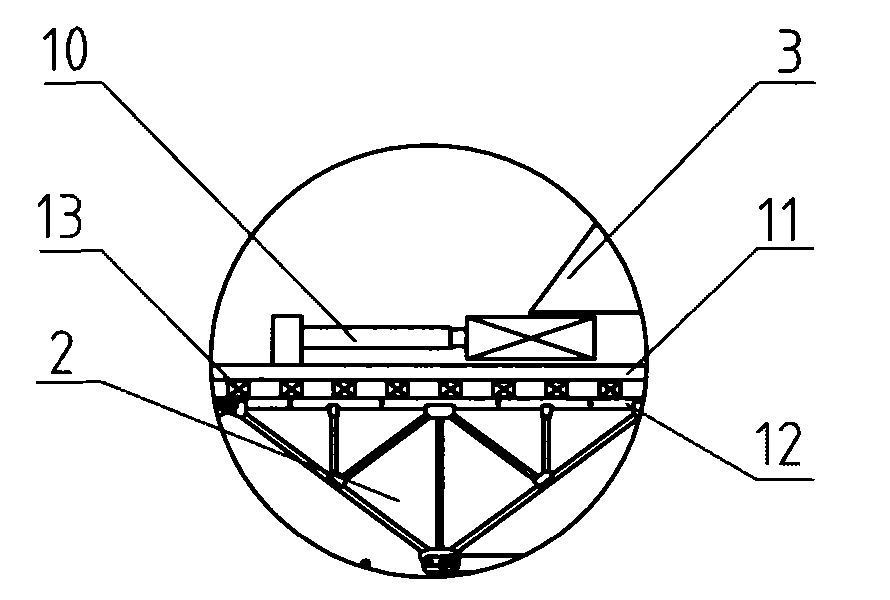

[0042] b. glideway is laid, vertically and evenly lay crossties 13 horizontally on the described construction beam, and the steel rail 11 as glideway is arranged left and right symmetrically above the sleepers;

[0043] c. assemble steel trusses, assemble steel truss beams on the frame;

[0044] d. The upper slideway is set, and the upper slideway matching the steel rail is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com