Non- water pigment ink

A non-aqueous, non-aqueous solvent technology, applied in the direction of ink, printing, copying/marking methods, etc., can solve problems such as the impact of paper transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

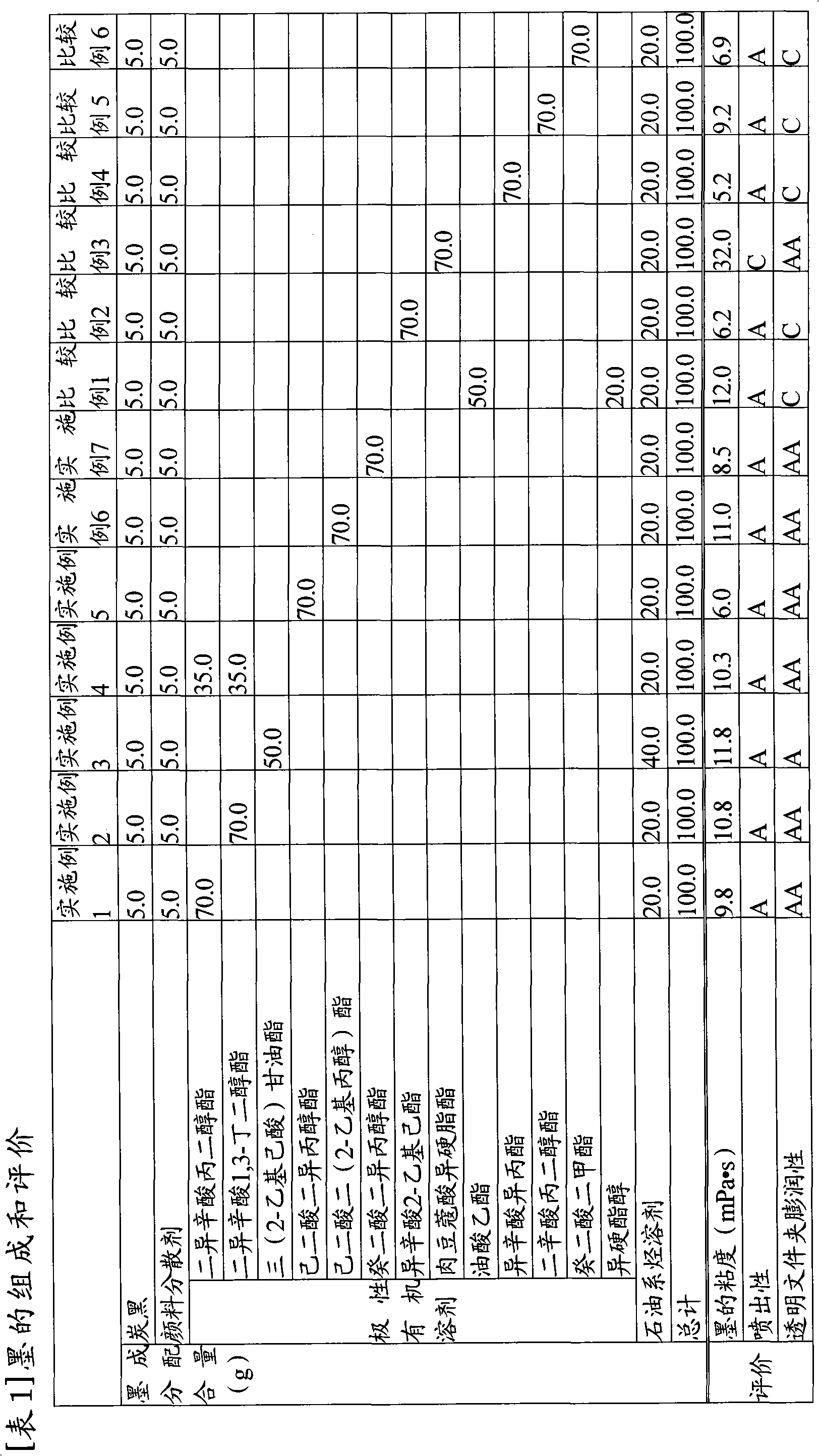

[0057] Hereinafter, the present invention will be described in detail through examples, but the present invention is not limited thereto.

[0058]

[0059] The ingredients shown in Table 1 were put into a 250ml polypropylene container and mixed, and 450g of zirconia beads (0.5mm in diameter) were put in, and a rocking mill (Rocking mill) (SEIWA GIKEN CO., LTD. ) dispersion for 60 minutes, and then, the zirconia beads were filtered, and the obtained contents were filtered with 3.0 μm and 0.8 μm membrane filters to remove dust and coarse particles to obtain respective inks.

[0060] The carbon black used was "MA11" manufactured by Mitsubishi Chemical Corporation, the pigment dispersant was "SOLSPERSE S-11200" manufactured by Lubrizol Japan Ltd., and the petroleum-based hydrocarbon solvent was "AF7 (naphthalene-based solvent) manufactured by NISCO Mitsubishi Corporation. ".

[0061] All of the obtained inks had a pigment particle diameter within an appropriate range for inkjet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com