Liquid-cooled electric machine and method for cooling such electric machine

A cooling coil and air cooling technology, applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of motor diameter and weight, limited heat conduction, and uncooled rotors, etc., to achieve compact structure and high efficiency The effect of cooling, simple configuration and fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

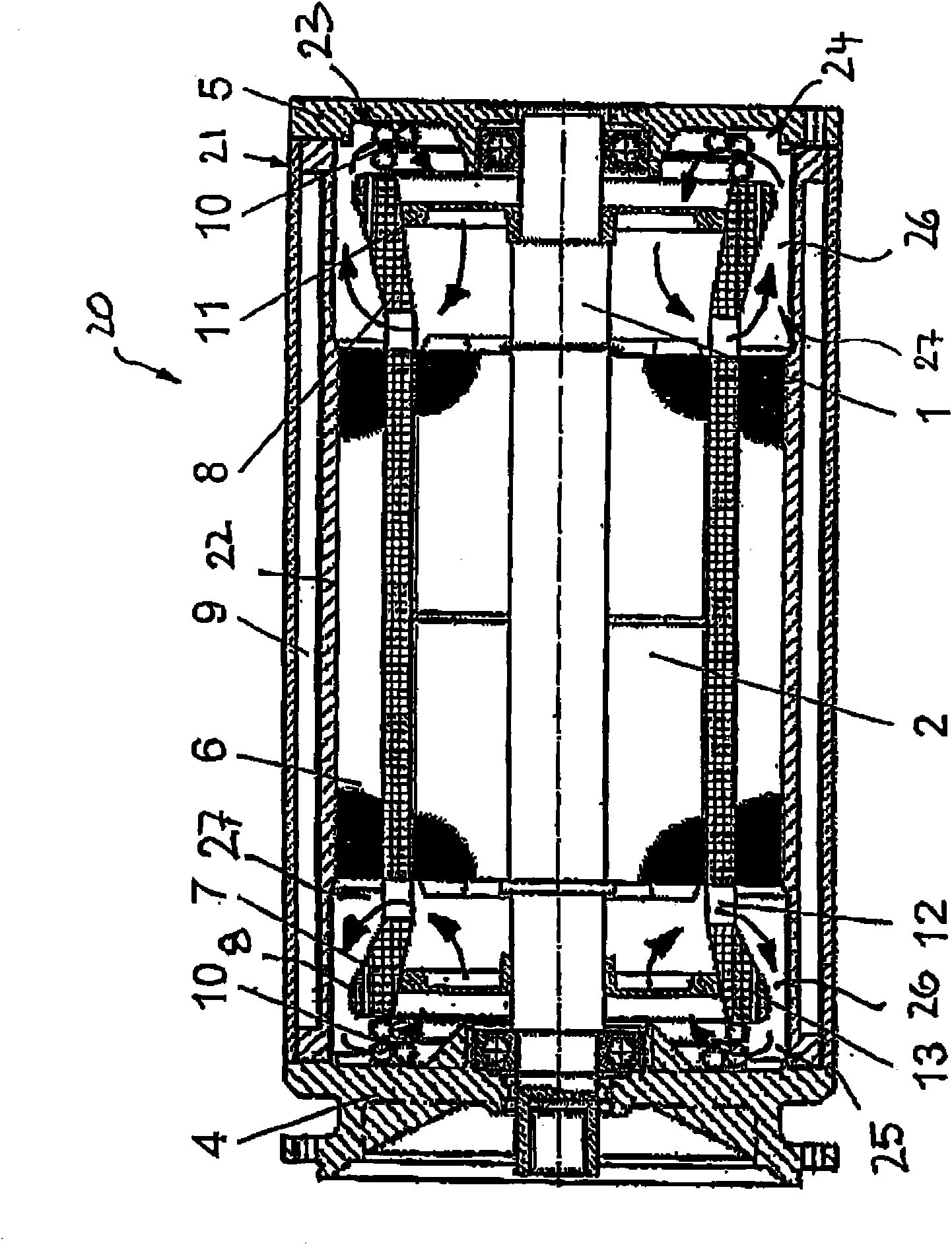

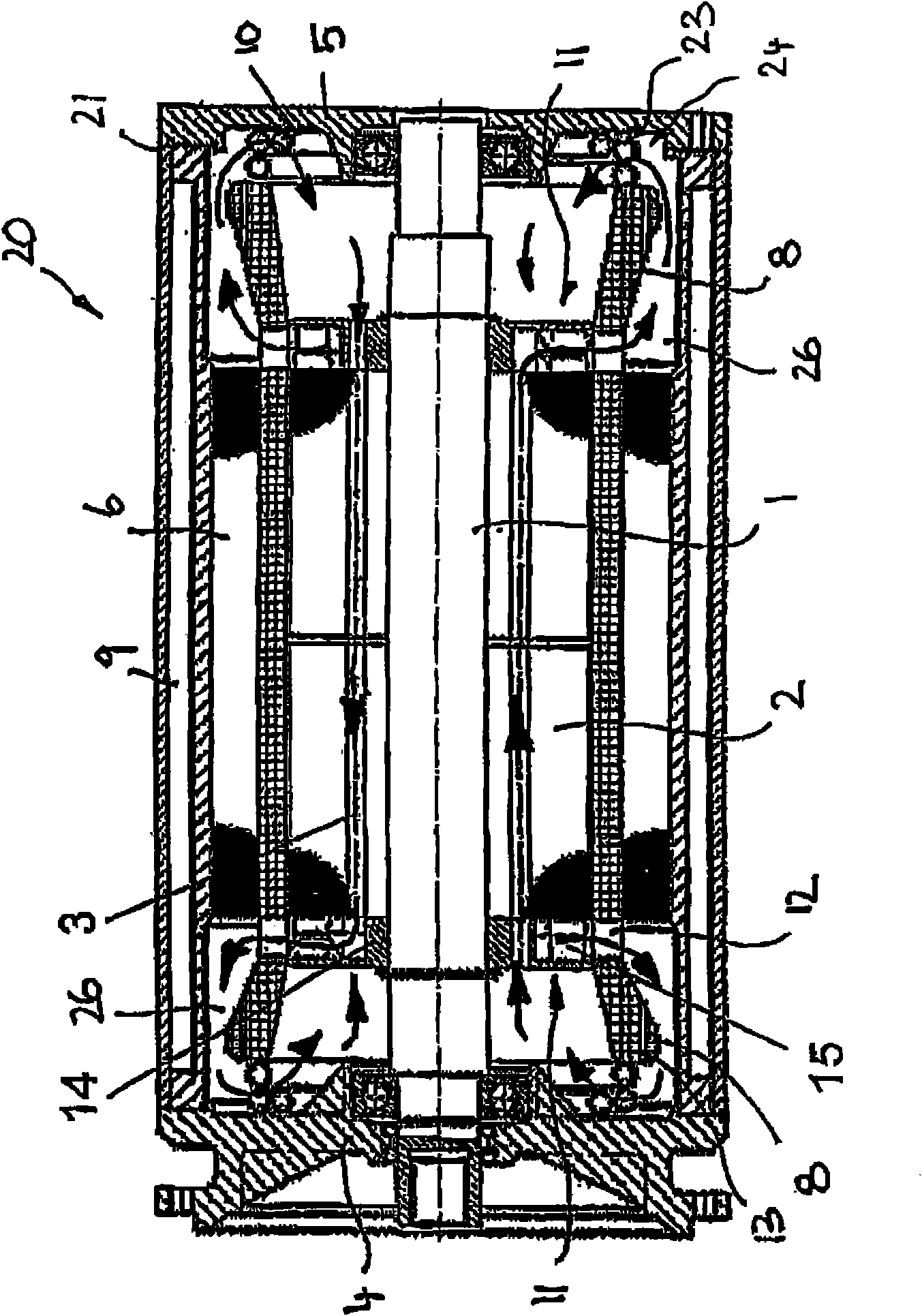

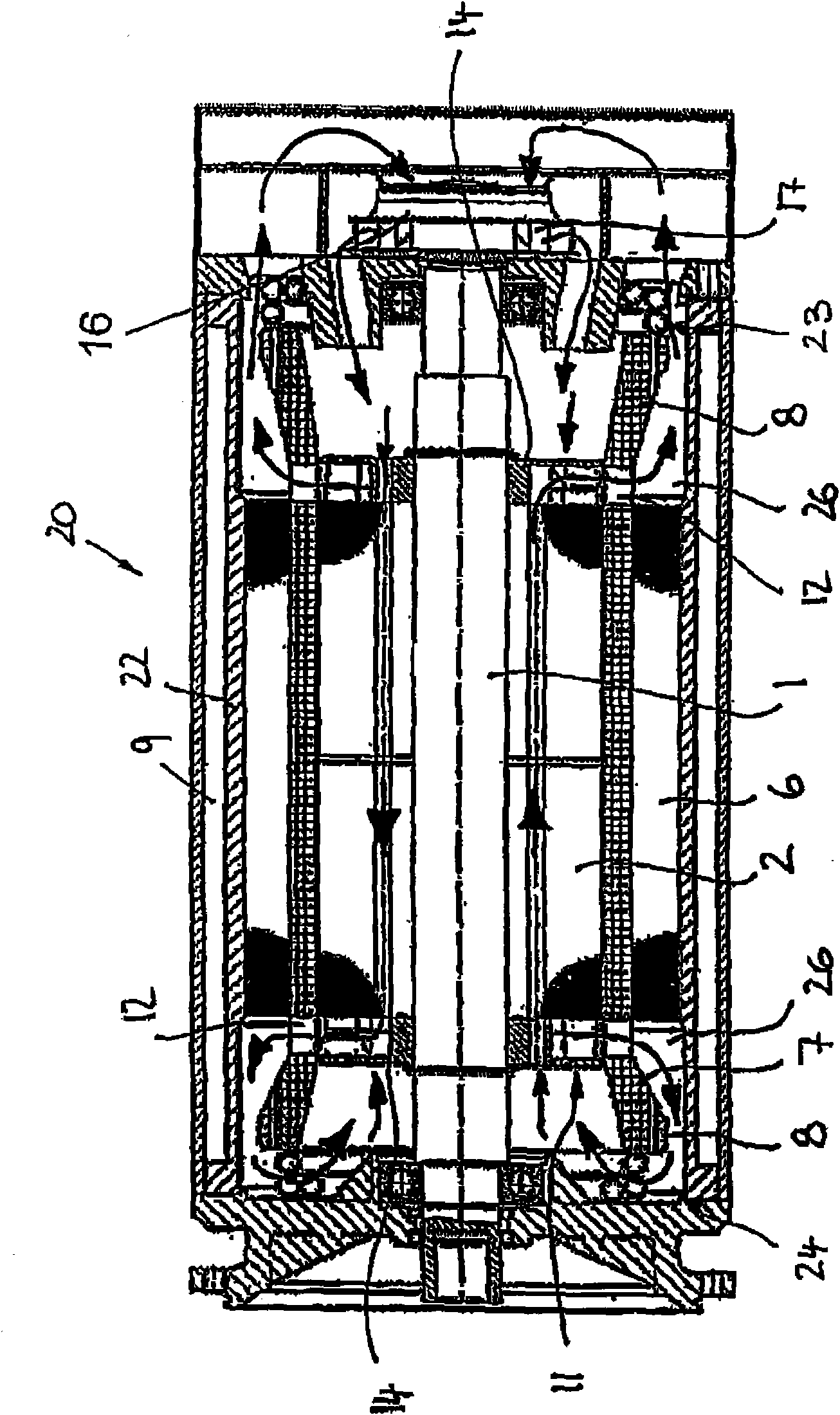

[0031] figure 1 The illustrated electric machine 20 comprises a shaft 1 with a rotor 2 which is rotatably mounted on end shields 4 and 5 which form part of a machine housing 21 and / or on the end faces thereof A closing jacket 22 surrounds the stator 6 of the machine 20 . The jacket 22 includes a jacket cooling device 9 through which a cooling liquid or liquid cooling circuit 23 circulates. The jacket is seated on the stator core without any horizontal and / or planar gaps, so that a good heat transfer from the stator 6 to the cooling jacket is achieved.

[0032] In addition to the liquid cooling circuit 23 described, the cooling device 24 of the electric machine 20 comprises an air cooling device 25 for cooling the winding ends 8 which protrude on both sides of the stator 6 and the rotor 2 from the housing 21 , more precisely, protrudes into the winding end space 26 defined by the jacket 22 and the end shields 4 and 5 . Such as figure 1 As shown, the stator 6 comprises a win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com