Support bar for trial assembling and adjusting of hydropower station tainter valve

An arc-shaped gate and trial assembly technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of inconvenient reuse of support rods, inconvenient force application of support rods, and inability to adjust in real time, so that the length can be adjusted immediately. Good adjustment, good rigidity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

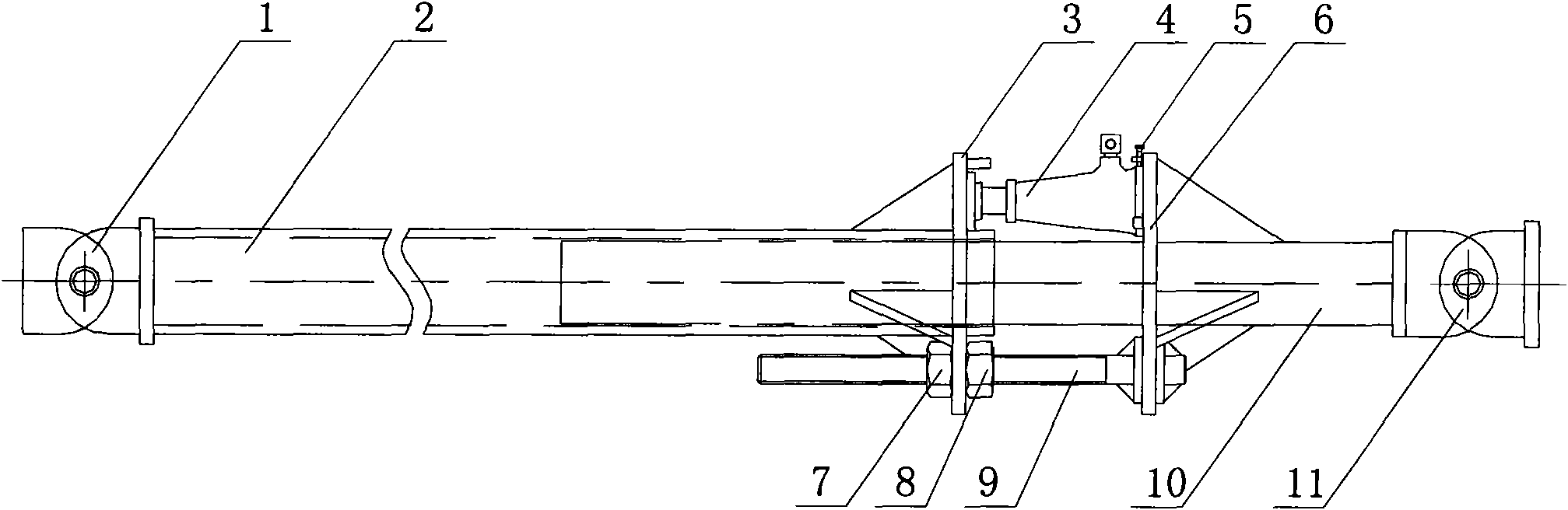

[0008] refer to figure 1 , a support rod for trial assembly and adjustment of arc gates in hydropower stations, comprising an upper hinge device 1, a lower hinge device 11, an outer steel casing 2, an inner steel casing 10, a jack 4, an upper bracket 3, a lower bracket 6, and a T-shaped Threaded stud locking mechanism, wherein the outer steel casing 2 and the inner steel casing 10 are movably socketed, and the upper hinge device 1 and the lower hinge device 11 are respectively arranged on the outer ends of the outer steel casing 2 and the inner steel casing 2 . The upper bracket 3 and the lower bracket 4 are respectively arranged on the outer steel casing 2 and the inner steel casing 10 sleeves, and the jack 4 and the T-shaped threaded stud locking mechanism are arranged on the lower bracket 6 and are located at corresponding positions on both sides of the support rod. The jack 4 is fixed with the lower bracket 6 through the locking stud 5, and the T-shaped locking mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com