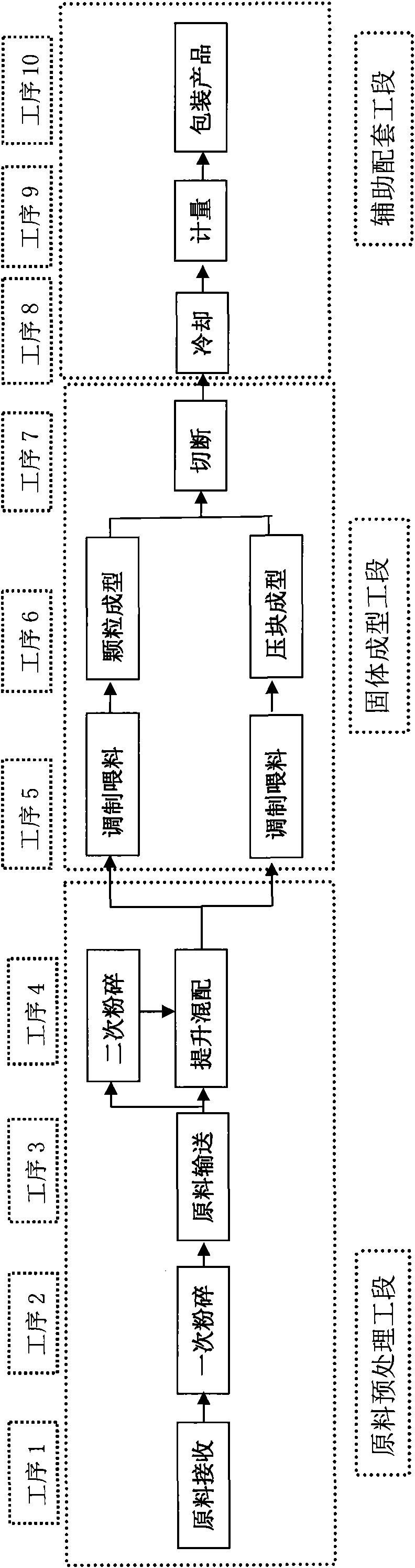

Processing method for biomass solid molding fuel

A technology of solid briquetting fuel and processing method, applied in solid fuel, biofuel, waste fuel and other directions, can solve the problems of low productivity, high energy consumption, poor operating environment, etc., to increase processing capacity, improve processing capacity, improve The effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

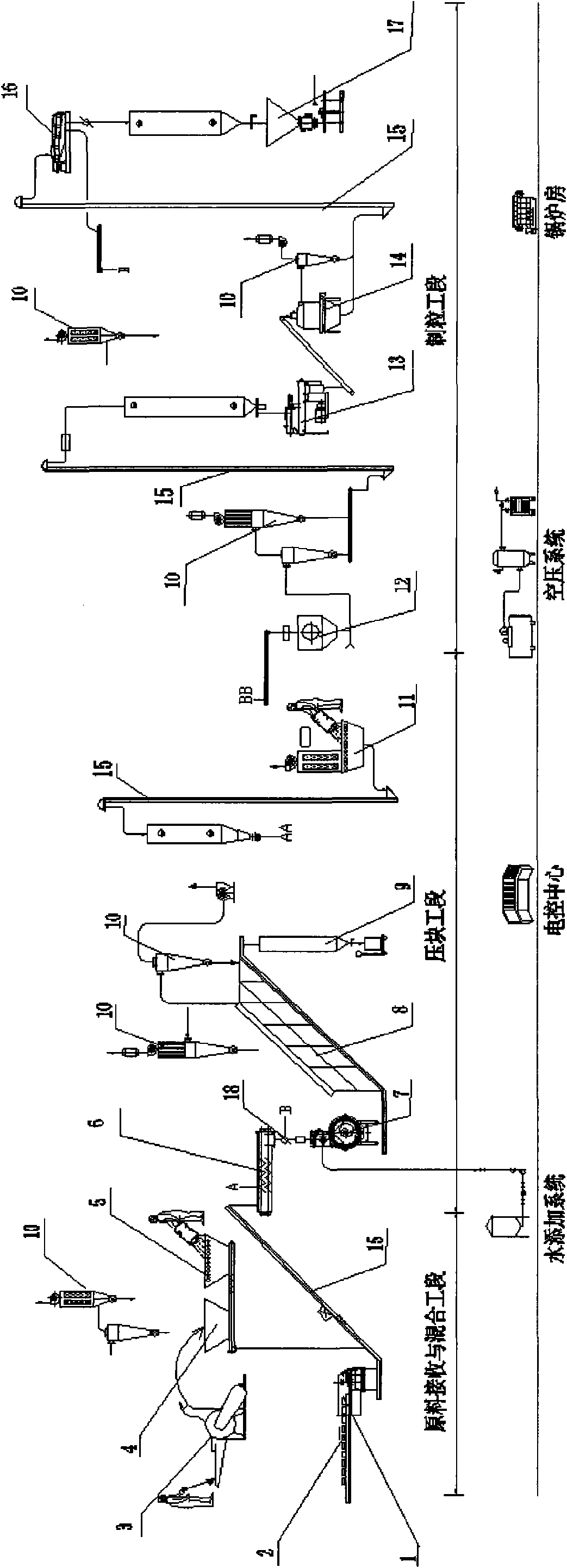

[0061] Example 1: Production of bulk briquettes from crop straws

[0062] The crushed crop stalks are manually or mechanically stacked in the raw material receiving device 1, and continuously conveyed by the scraper conveying device 2, which can ensure that the raw materials are fully dried and mixed, and the moisture content is consistent. At the same time, according to the requirements of feeding speed and molding speed, the main raw material is prepared in the raw material kneading and crushing device 3, and then enters the raw material inlet 4 after kneading. If the final straw has a high water content, peanut shells should be added, which is conducive to shaping. All the raw materials are lifted to the raw material mixing bin 6 through the scraper conveying device 15 for mixing. Simultaneously can add other additives such as pulverized coal according to user's requirement, therefore through pulverized coal adding device 11 (such as figure 2 Middle AA place) is connecte...

Embodiment 2

[0063] Example 2: Production of pelletized fuel from crop straws

[0064] The requirement of granular briquette fuel is higher than that of block briquette fuel, and the raw material needs secondary crushing. The specific implementation process is as follows:

[0065] The crushed crop stalks are manually or mechanically stacked in the raw material receiving device 1, and continuously conveyed by the scraper conveying device 2, which can ensure that the raw materials are fully dried and mixed, and the moisture content is consistent. At the same time, according to the requirements of feeding speed and molding speed, the main raw material is prepared in the raw material kneading and crushing device 3, and then enters the raw material inlet 4 after kneading. If the final straw has a high water content, peanut shells should be added, which is conducive to shaping. All the raw materials are lifted to the raw material mixing bin 6 through the scraper conveying device 15 for mixing. ...

Embodiment 3

[0067] Example 3: Production of block and granule fuel from crop stalks

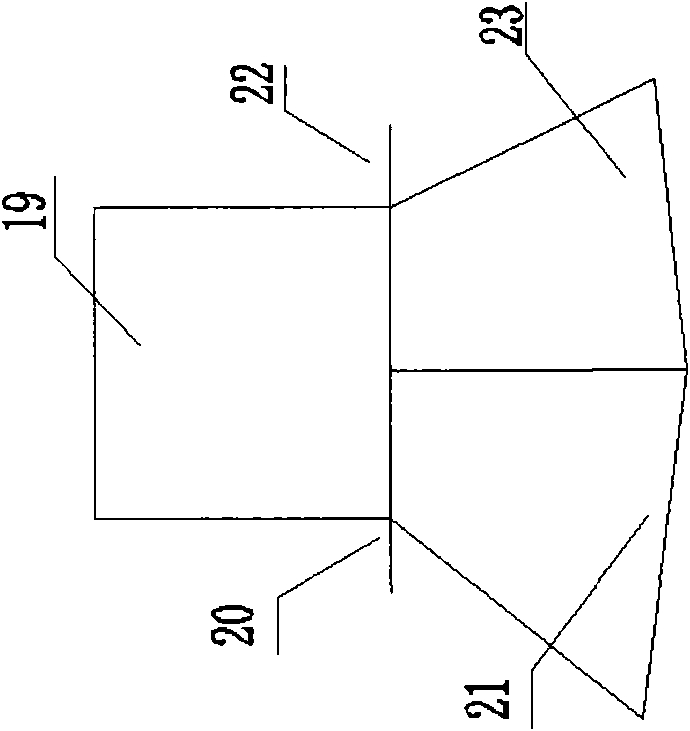

[0068] According to market demand and raw material situation, this process route can pass through pneumatic tee 18, namely figure 2 In the B place, open the pipeline switches 21 and 23 entering the briquetting section and the granulation section simultaneously, and connect the particle fuel interface 23 to the BB place, so that the machine can produce block and particle molding fuel simultaneously. The working process is the same as in Examples 1 and 2.

[0069] Under normal working conditions, the biomass solid briquette fuel production line built by the present invention is controlled by the electric control center throughout the processing process, including the main control of the central control room and the individual control of main equipment. The main control room is responsible for the start-up and operation monitoring of the entire production line and shutdown, the single control is responsib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com