Preparation method and use method of biologically degradable shape memory tubular support stent

A biodegradable, tubular support technology, applied in stents, medical science, prostheses, etc., can solve problems such as the need for external high temperature, the inability to precisely control the glass transition temperature of the final product in advance, and the pain of patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A specific embodiment of the present invention is a method for preparing a biodegradable shape memory tubular support stent, the steps of which are:

[0031] A. Preparation of biodegradable shape memory polymer material with a glass transition temperature of 5-37°C.

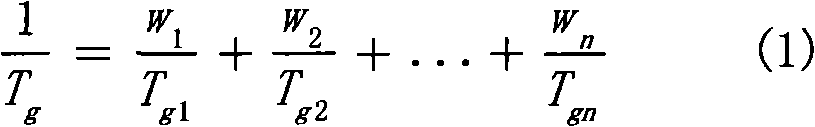

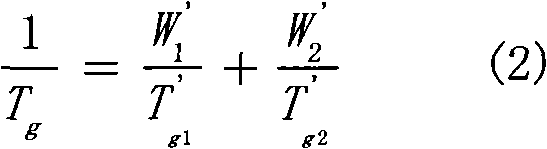

[0032] Physical blending method: at least one biodegradable shape memory polymer material with a glass transition temperature lower than 37°C is physically blended with at least one biodegradable shape memory polymer material with a glass transition temperature higher than 37°C; The mass ratio between the polymer materials used for blending is determined by the following formula (1):

[0033] 1 T g = w 1 T g 1 + w 2 T ...

Embodiment 2

[0040] This example is basically the same as Example 1, except that the biodegradable shape-memory polymer material with a glass transition temperature higher than 37°C is changed to poly-L-lactic acid with a molecular weight of 180,000, and its glass transition temperature (T g1 ) is 58°C. Calculate according to formula (1), the mass ratio W of poly-L-lactic acid and poly-ε-caprolactone 1 :W 2 It is 83:17.

Embodiment 3

[0042] This example is basically the same as Example 1, except that the glass transition temperature is lower than 37° C. The biodegradable shape memory polymer material is changed to polydioxanone, and its glass transition temperature (T g1 ) is 5°C. Calculate according to formula (1), the mass ratio W of poly DL-lactic acid and polydioxanone 1 :W 2 It is 52:48.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com