Dual-redundancy switch reluctance motor

A switched reluctance motor, dual redundancy technology, applied in the direction of magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as low reliability, improve efficiency, improve System performance, the effect of improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

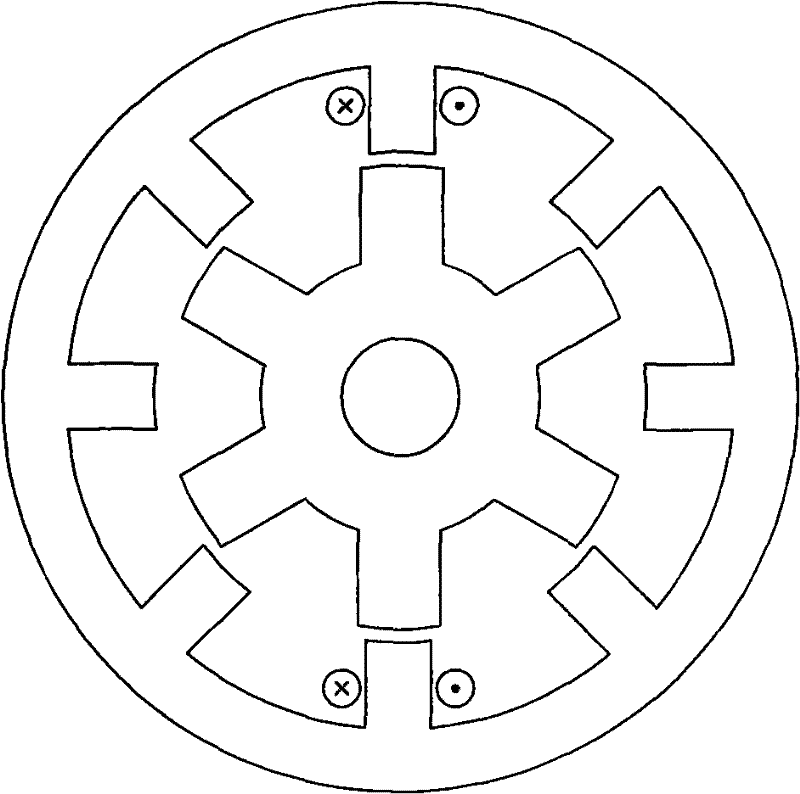

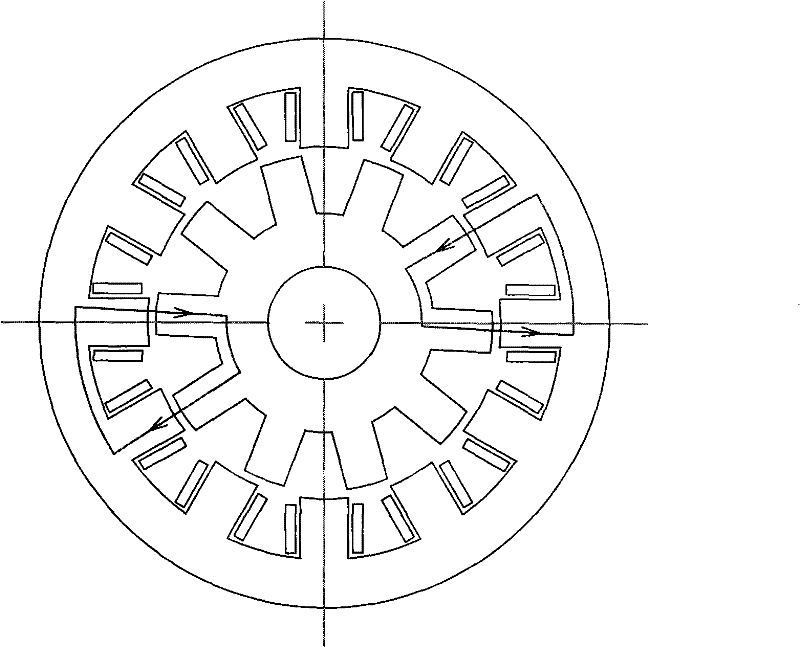

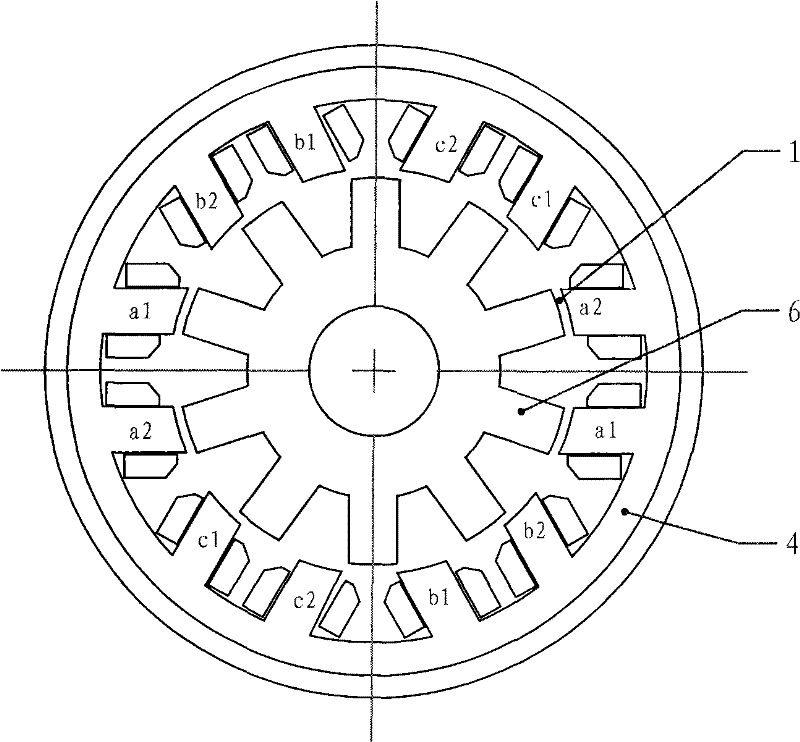

[0011] The double-redundancy switched reluctance motor described in this embodiment includes an air gap 1, a rotor core 6, and a stator core 4. It also includes two sets of three-phase windings. There are 10 rotor teeth on the rotor core 6, and the stator core 4 There are 12 stator teeth on it, and the same-phase windings of each set of three-phase windings are symmetrically wound on the stator teeth of the stator core 4, and form magnetic fluxes in the same direction. Two in-phase windings belonging to two sets of three-phase windings on two parallel stator teeth form magnetic fluxes in opposite directions, forming a short magnetic circuit structure.

[0012] Both the stator core 4 and the rotor core 6 of the motor in this embodiment have a salient pole structure.

[0013] The arrangement order of the two sets of three-phase windings on the stator teeth is:

[0014] a1→a2→c1→c2→b1→b2→a1→a2→c1→c2→b1→b2.

[0015] The arrangement order of the two sets of three-phase windings o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com