Method for processing maize milk beverage by using gold corn

A technology of sweet corn and corn steep liquor, which is applied in the field of processing corn steep liquor beverages with ultra-sweet and tender corn, which can solve the problems of short shelf life, false gel, precipitation, etc., and achieve the effects of avoiding stratification, maintaining fragrance and taste, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

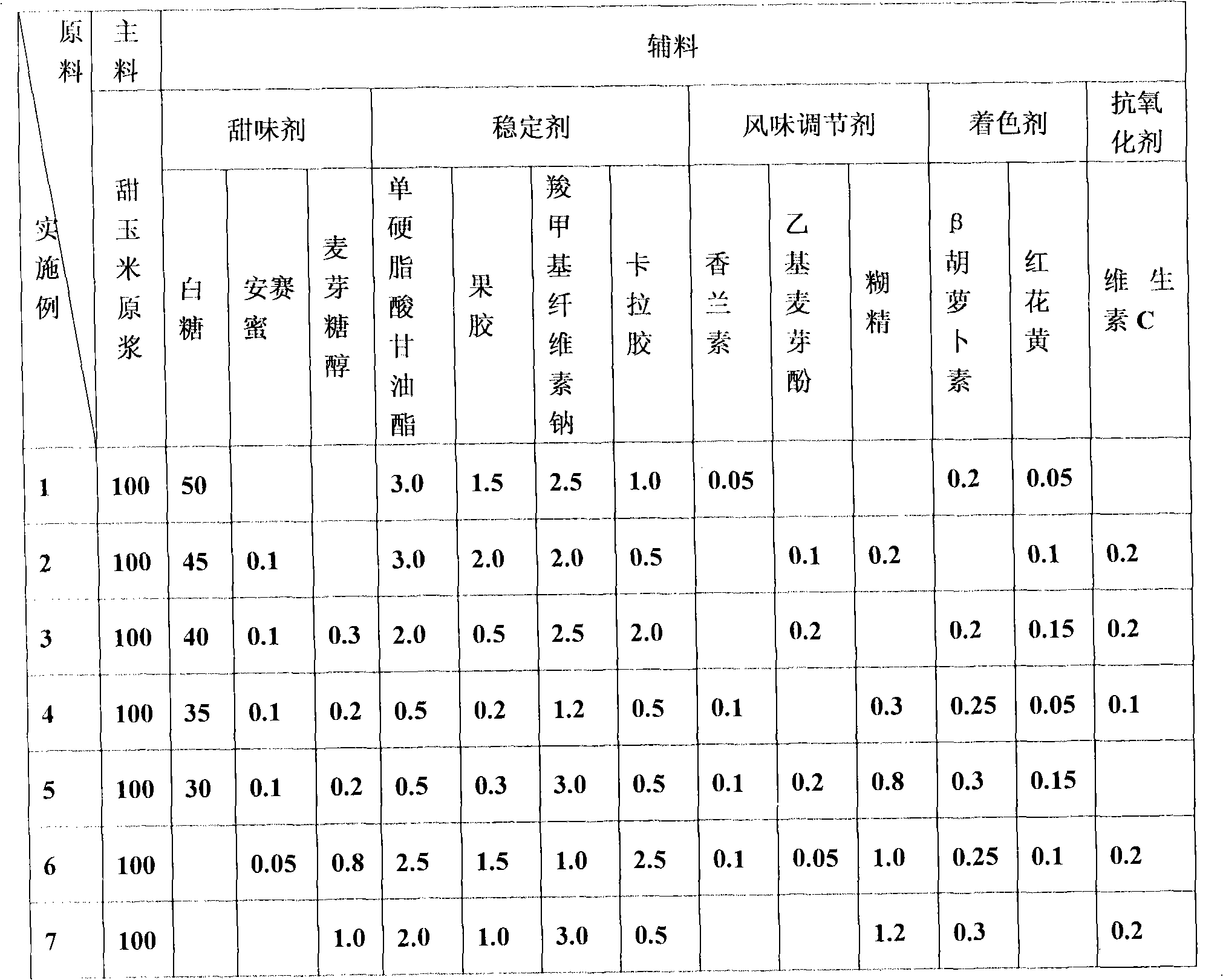

[0018] Corn syrup beverage ingredient list

[0019]

[0020] The list of sweetener ingredients only lists white sugar, acesulfame potassium, and maltitol, and it is also feasible to add one or a combination of aspartame, sucralose, xylitol, fructose, or glucose.

[0021] Preparation method 1: According to the ratio provided in the ingredient list, take 100 parts of corn puree,

[0022] Preparation of mixed solution: mix 1-50 parts of sweetener, 0.2--8 parts of stabilizer, 0.05-1.2 parts of flavor regulator, 0.1-0.45 parts of coloring agent and 0-0.2 parts of antioxidant Emulsify and dissolve for 10-20 minutes at a temperature of 80°C to obtain a mixed solution; the stabilizer is one or a combination of glyceryl monostearate, sodium carboxymethylcellulose, carrageenan, sucrose fatty acid ester, xanthan gum or pectin more than one combination.

[0023] After mixing the corn puree and the mixed liquid, heat it in a sealed insulation tank to 72°C-75°C for gelatinization treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com