Structure of operating part of explosion prevention button head

A technology of operating parts and operating parts, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of ineffective prevention of water ingress and achieve good protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

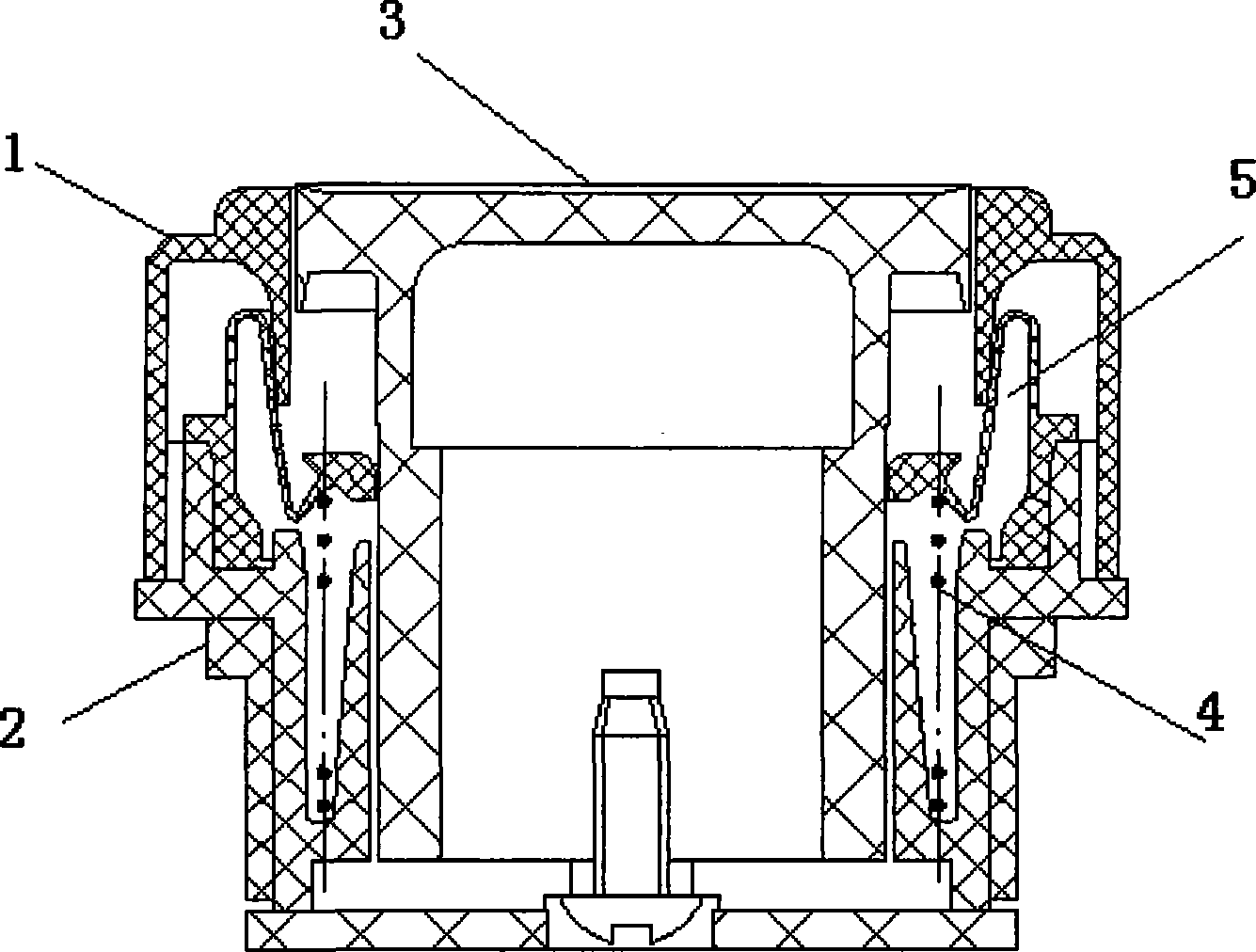

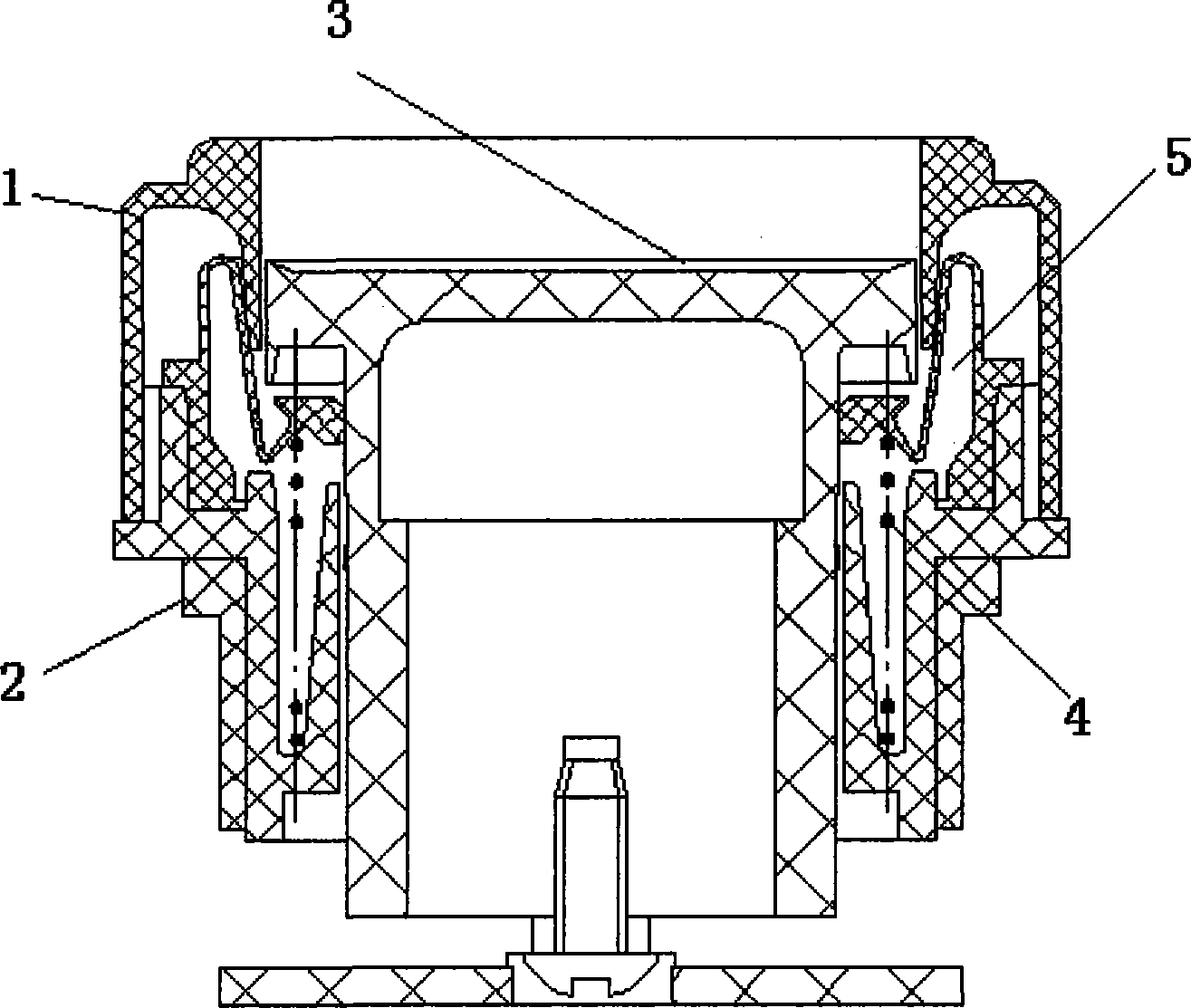

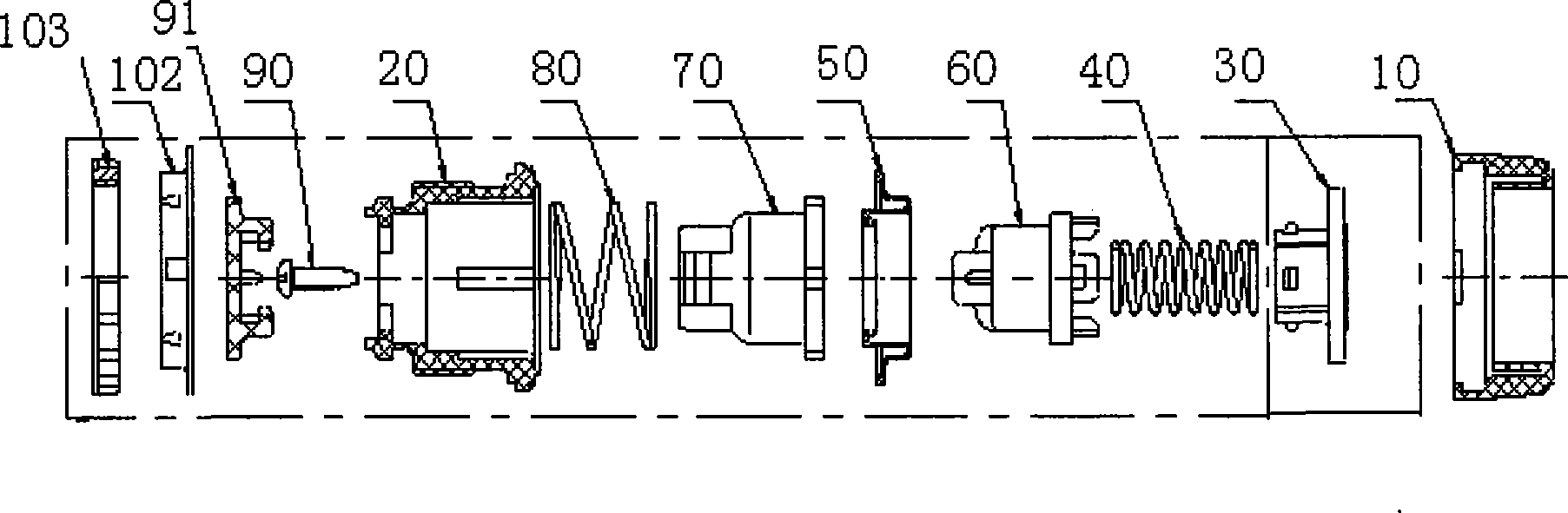

[0014] by image 3 It can be seen that the present invention includes: a cover 10, a body 20 connected with the cover 10; in the cavity formed by the cover 10 and the body 20, it also includes an operating member 30 on the upper part of the cavity and a stopper on the lower part of the cavity. A plate 91; a first spring 40, a compression ring 60, a telescopic sealing ring 50, a movable shaft 70, a second spring 80 are sequentially arranged under the operating member 30; also includes a fixing mechanism 90; the fixing mechanism 90 It is placed under the movable shaft 70, and the body 20 and the cover 10, and the compression ring 60 and the movable shaft 70 are integrated by the connection and transition of the telescopic sealing ring 50;

[0015] The operating component 30 is a flat head type, a lock head type, a mushroom head type, or an optional type;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com