Production data processing method and data acquisition device

A data collector and production data technology, applied in the field of data processing, can solve the problems of wasting paper, inefficient production management, and spending a lot of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

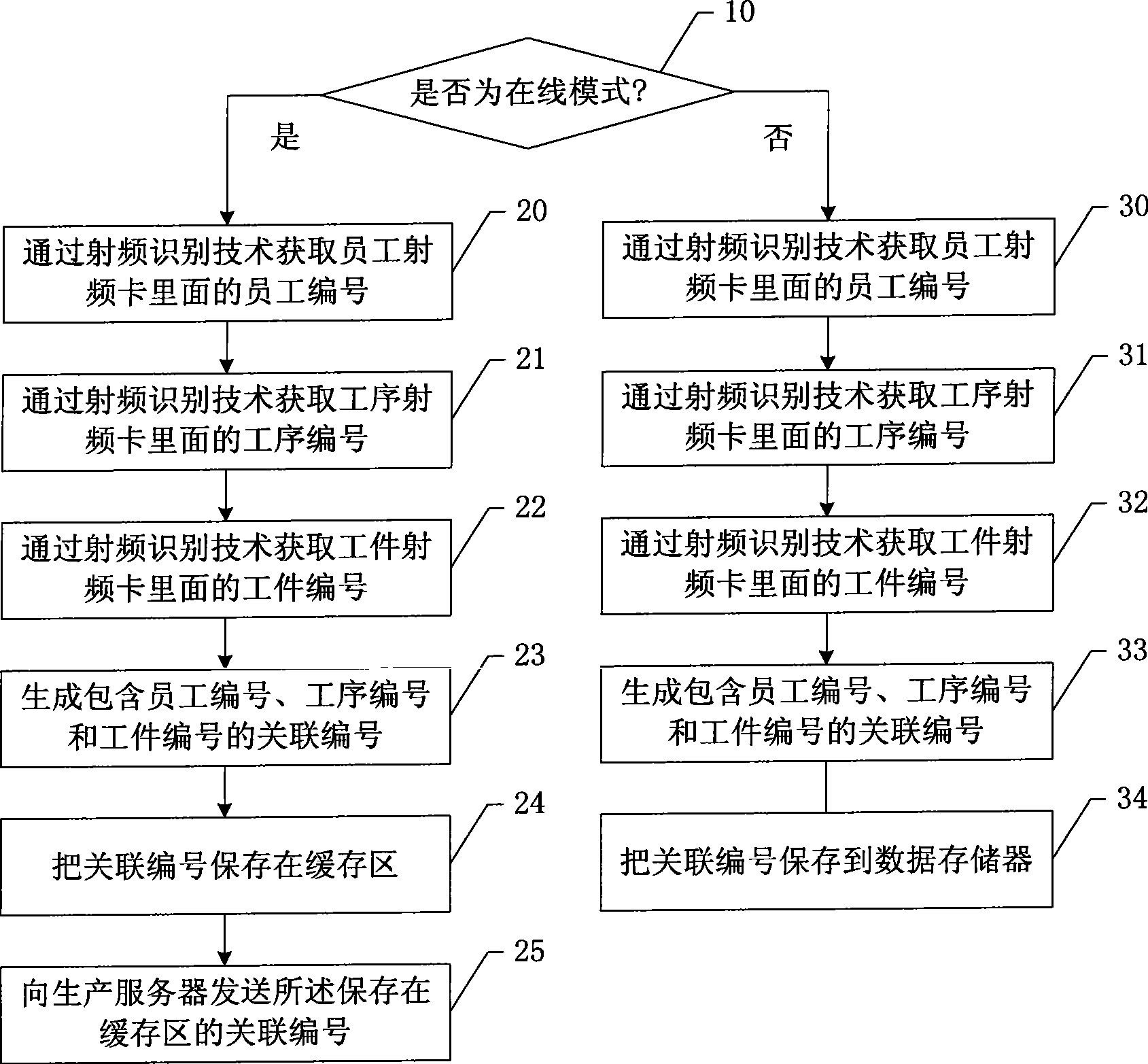

[0037] Please refer to figure 1 , is a flowchart of a production data processing method according to an embodiment of the present invention. The production data processing method on the production line includes the following steps.

[0038] Step 10. The data collector judges whether it is in online mode, if yes, proceed to steps 20 to 25, otherwise, proceed to steps 30 to 34.

[0039] There are several methods for the data logger to determine the mode. Method 1: The data collector is provided with a communication interface. When the data collector is turned on, it can detect whether it has established a connection with the production server. If so, it is determined to be in the online mode. Method 2: The data collector is equipped with a keyboard, and the online mode and offline mode are manually set through the keyboard.

[0040]In the online mode, the data collector is connected to the production server online, the associated number is stored in the buffer, and the data c...

Embodiment 2

[0061] Please refer to figure 2 , is a schematic structural diagram of the data collector of the embodiment of the present invention. The data collector comprises: antenna 44, radio frequency module 45 using radio frequency identification technology, liquid crystal display 41, keyboard 42, single-chip microcomputer system 46, external communication interface 47, data memory 49; Antenna 44 is connected with radio frequency module 45, single-chip microcomputer system 46 and The radio frequency module 45, the liquid crystal display 41, the keyboard 42, the communication interface 47, and the data memory 49 are connected.

[0062] Wherein, the single-chip microcomputer system 46 includes:

[0063] The mode determination unit is used to determine whether the data collector is in the online mode, and if so, send the online mode information to the online employee numbering unit, otherwise, send the offline mode information to the offline employee numbering unit.

[0064] The onlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com