Device for measuring trans-critical cycle heat exchange of CO2-oil mixture

A cyclic heat exchange and transcritical technology, applied in the direction of material thermal conductivity, etc., can solve problems such as increased manpower and time consumption, low internal pressure, and inability to inject lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

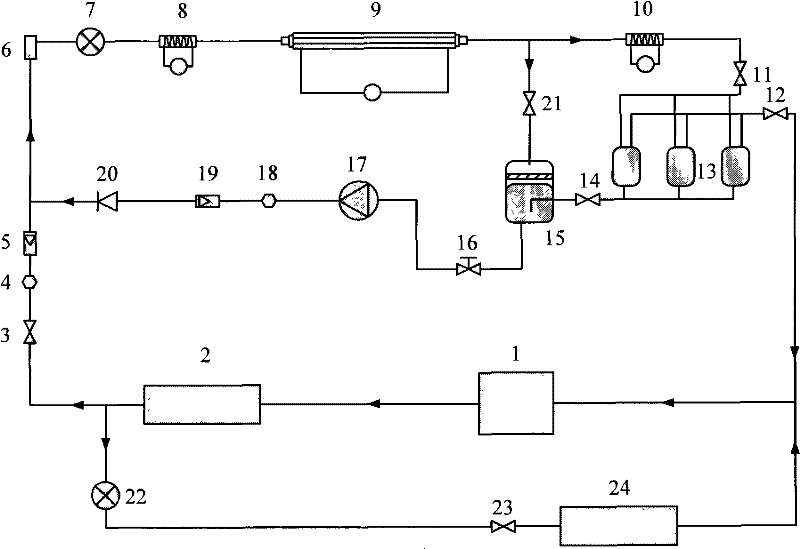

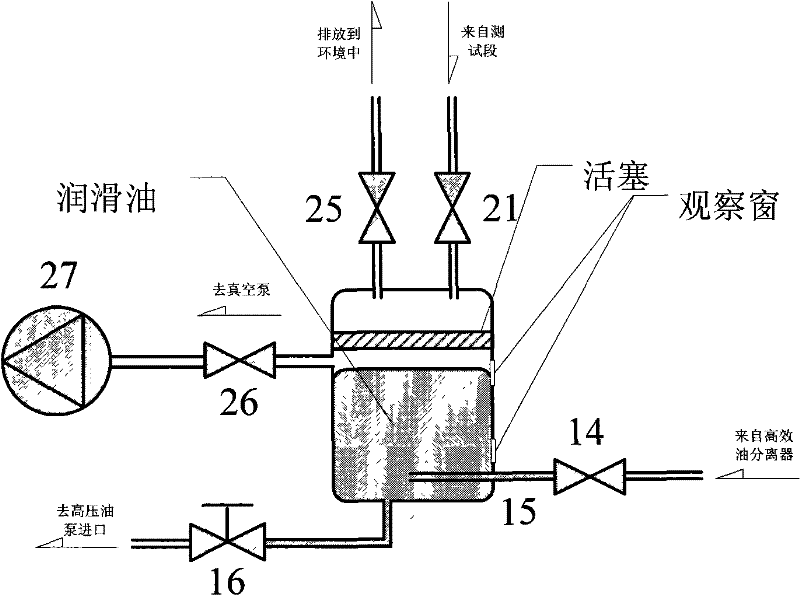

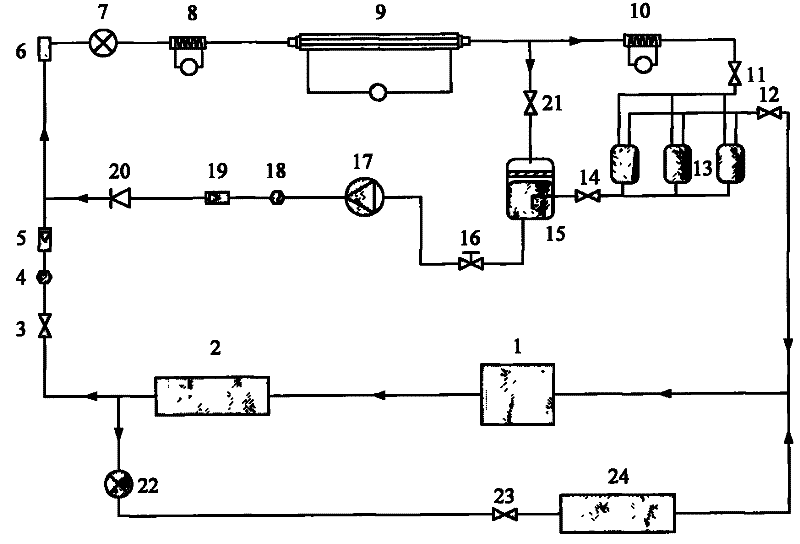

[0028] Such as figure 1 As shown, this embodiment includes a loop and two branches: CO 2 Measuring circuit, CO 2 Bypass branch and lubricating oil branch.

[0029] CO 2 The measurement circuit includes: compressor module 1 (Dorin TCS340 / 4-D), condenser 2 (FUJITSU), first stop valve 3 (Swagelok SS-10NBSW8T-G), first sight mirror 4 (Danfoss SGN), CO 2 Mass flow meter 5 (Emerson 5860E), mixing chamber 6, first electronic expansion valve 7 (FUJIKOKIEDM-4QYPKG-1YD2), preheater 8, CO 2 Transcritical cycle heat transfer characteristic test section 9, post heater 10 (custom-made), second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com