Open type ring flange for fastening high-pressure oil tube

A high-pressure oil pipe, tightening technology, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of low production efficiency, short service life, large material consumption, etc., to achieve high manufacturing production efficiency, The effect of long service life and high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

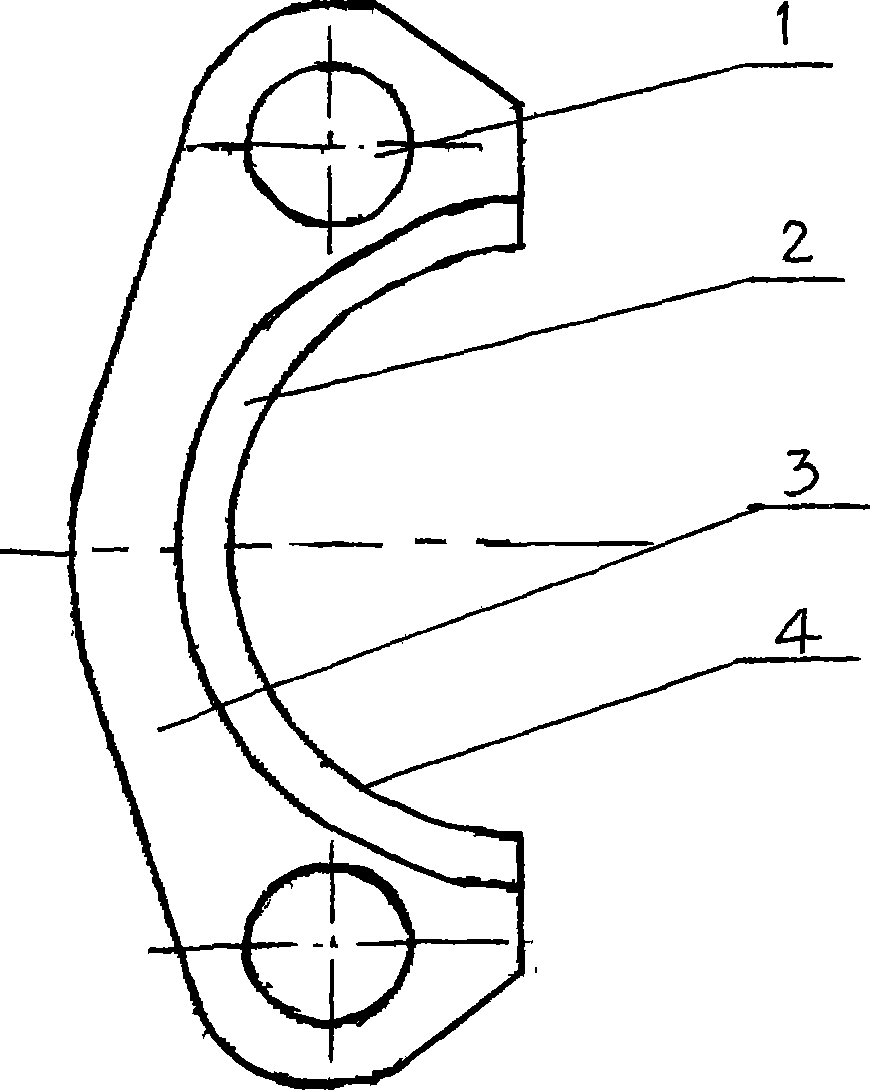

[0011] Such as figure 1 , 2 As shown, a set of products of the present invention includes two sets of flange bodies 3 with the same shape and structure. During use, the two sets of flange bodies 3 are installed from the two sides of the oil pipe respectively, and the mating surface 4 of the flange body 3 is in contact with the flange body 3. The outer wall of the oil pipe is matched and contacted. The flange body 3 is made of No. 45 steel through forging.

[0012] The inner wall surface of the flange body 3 is the so-called mating surface 4 . Below the mating surface 4 , that is, an annular sealing groove 2 is processed on the inner wall of the lower end of the flange body 3 . The upper end of the flange body 3 is a reinforcing rib 5 integrally constructed, and the inner wall surface of the reinforcing rib 5 is also a mating surface. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com