An automatic foam proportional mixing digital display controlling module

A technology of proportional mixing and control module, applied in various fluid ratio control, mixer, dissolution and other directions, can solve the problems affecting the accuracy of terminal liquid output ratio, dynamic deviation of system characteristics, inconvenient use, etc., to improve system reliability, The effect of reducing performance requirements and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

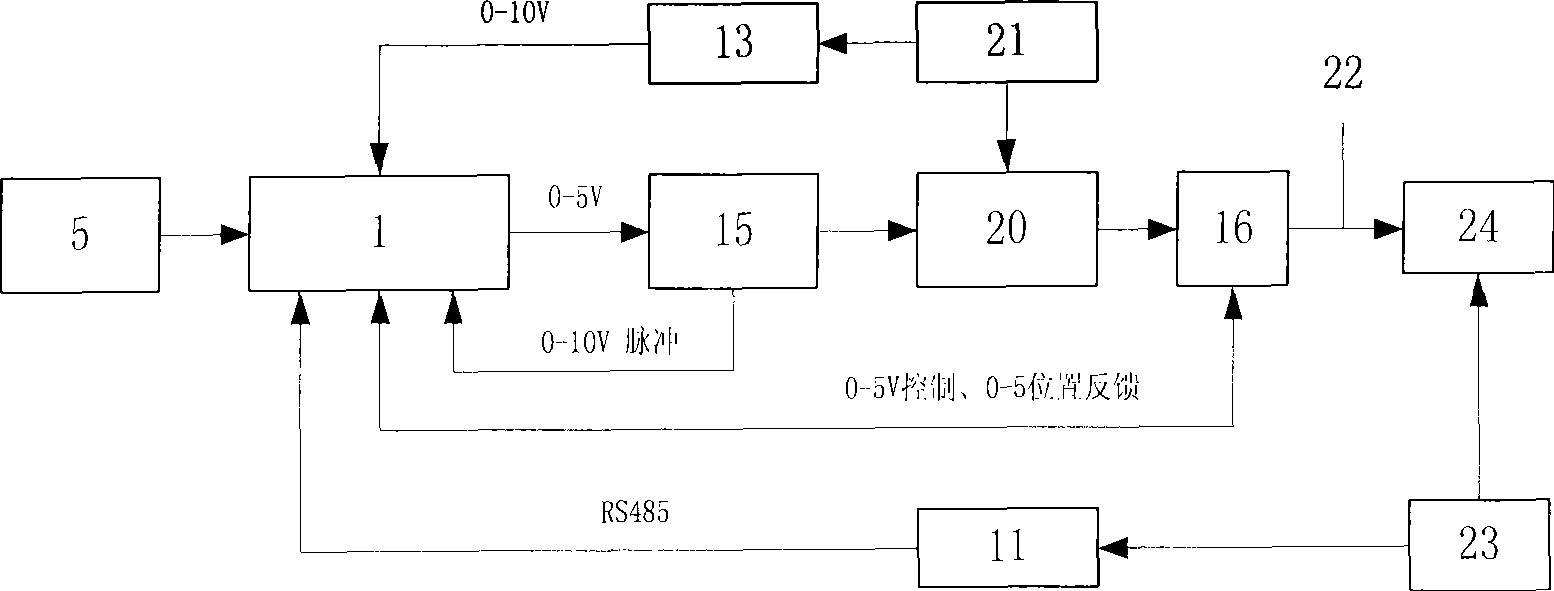

[0038] Embodiment 1, its structure is as image 3 As shown, the water flowmeter 11 adopts an electromagnetic flowmeter and is installed in the water supply circuit 23 , and the liquid level sensor 13 adopts a reed type liquid level switch and is installed in the foam liquid tank 21 . The microcomputer control unit 1 is connected to the water flow meter 11 through the RS485 interface, connected to the DC brushless motor driver 15 through the 0-5V analog output interface and the 0-12V pulse input interface, and connected to the electronic control valve driver 16 through the 0-5V analog input and output interface, The liquid level sensor 13 is connected through the 0-10V interface, and the display operating mechanism 5 adopts an 8-digit liquid crystal digital display. The water flow parameter and the motor speed parameter form a single-parameter feedback closed-loop control loop, and the microcomputer control unit 1 stores the speed and flow characteristic curve parameters and th...

Embodiment 2

[0039] Embodiment 2: its structure is as Figure 4 As shown, the water flow meter 11 adopts a differential pressure flow meter and is installed in the water supply circuit 23 , and the liquid level sensor 13 adopts a photoelectric liquid level switch and is installed in the foam liquid tank 21 . The microcomputer control unit 1 is connected to the differential pressure flowmeter through the 4-20mA interface, connected to the turbine foam flowmeter 12 through the 0-10V pulse input interface, connected to the 0-5V analog output interface, and 0-12V pulse input interface to the DC brushless motor driver 15. Connect the liquid level sensor 13 through the 0-5V interface, and the display operating mechanism 5 adopts a 640×480 dot matrix color liquid crystal display. The water flow parameter, the foam flow parameter and the speed parameter of the foam pump unit 20 constitute a double-parameter feedback closed-loop control loop. In actual work, the water supply flow rate reaches the ...

Embodiment 3

[0040] Embodiment 3: as Figure 5 As shown, the water flowmeter 11 adopts a turbine flowmeter and is installed in the water supply circuit 23 , and the liquid level sensor 13 adopts a Hall type liquid level switch and is installed in the foam liquid tank 21 . The microcomputer control unit 1 is connected to the turbine flowmeter through the 0-10V pulse input interface, connected to the pressure sensor 14 through the 0-5V interface, connected to the Hall type liquid level switch through the 0-10V interface, and connected to the DC brushless motor driver 15 through the RS485 interface , Connect the electronically controlled valve driver 16 through the 0-5V interface, and the display operating mechanism 5 adopts an 8-digit LED digital display. Water flow parameters, outlet pipeline pressure parameters and motor speed parameters constitute a dual-parameter feedback closed-loop control loop. The microcomputer control unit pre-stores the rotational speed and flow characteristic cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com