Two-port testing method of alternating current milliohm meter

A test method and end-to-end technology, applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problem that test lines affect test accuracy and test stability, cannot achieve high precision and test stability, and couple inductance and large parasitic inductance, etc., to achieve the effect of reducing purchase cost and maintenance cost, good electrical shielding performance, and reducing inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

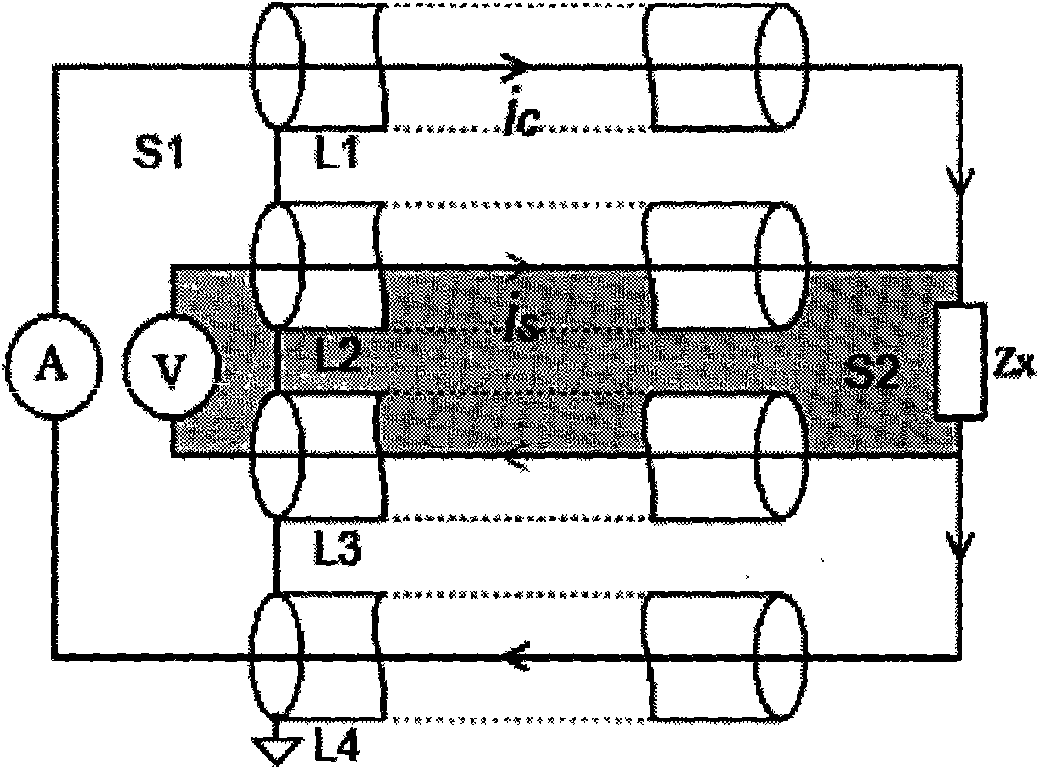

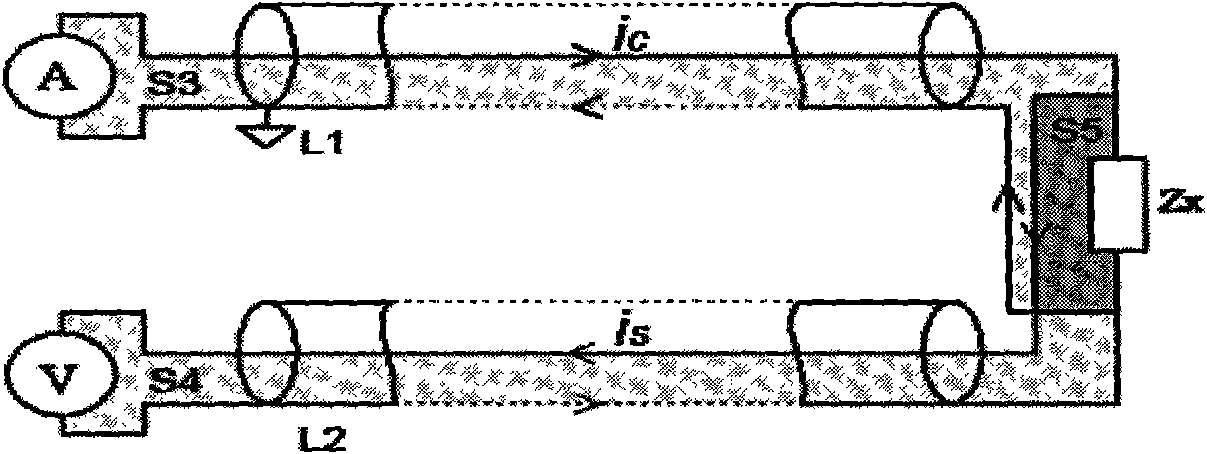

[0022] Such as figure 2 As shown, connect one end of a coaxial cable L1 to the excitation source circuit, and connect the shielding layer of the coaxial cable L1 to the ground wire of the excitation source circuit; connect one end of the other coaxial cable L2 to the sampling circuit phase The shielding layer of the coaxial cable L2 is connected to the input of the negative terminal of the sampling circuit, and its inner core wire is connected to the input of the positive terminal of the sampling circuit; the other ends of the two coaxial cables are respectively connected to the two ends of the Zx under test. This connection method makes the excitation current ic of the excitation circuit (see the arrow for the flow direction) flow through the inner core of the coaxial cable L1, then flow through the device under test Zx, and then flow back to the excitation source through the shielding layer of the coaxial cable L1. The current loop area is the sum of S3 and S5. Since S3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com