Supporting leg and universal wheel for heavy equipment

A technology of heavy equipment and universal wheels, which is applied in the direction of casters, wheels, transportation and packaging, etc. It can solve the problems of uneconomical, inability to adjust height and level, and inapplicability, so as to prevent deformation and ground damage, and reduce the force on rollers Unevenness, the effect of reducing equipment vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0011] The present invention is composed of a multi-spherical universal wheel A, a spiral support foot B, a high-performance damping pad (12) and a bolt washer (13), except for the felt ring oil seal (6) and the damping pad (12) Outside, all are metal parts; Every heavy equipment uses the quantity of the present invention at least more than three.

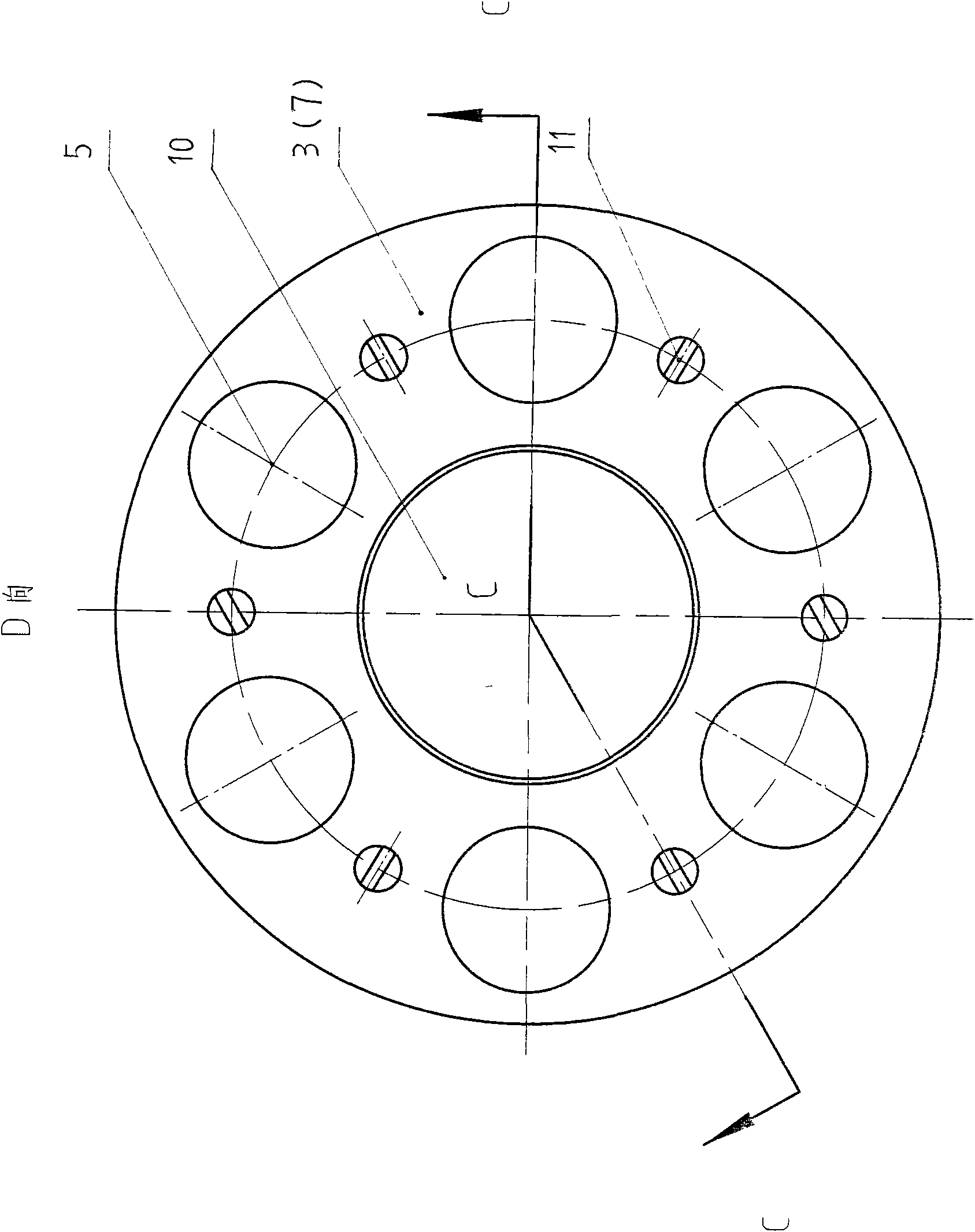

[0012] Multi-spherical universal wheel A is made up of wheel disc (3), small steel ball (4), ball roller (5), felt ring oil seal (6), retaining ring (7) and screw (11). A plurality of ball rollers (5) are evenly distributed on the same circumference of the same roulette (3), and the number is 3 to 12, which are used to share different equipment weights; each ball roller (5) is densely covered with a circle of small Steel ball (4) can be rotated in any direction to improve its rolling performance, so i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com