Welding joint conveying device on inner surface of piping

A conveying device and inner surface technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of limited working time, poor welding, unusable, etc., achieve correct welding, reduce costs, and expand the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

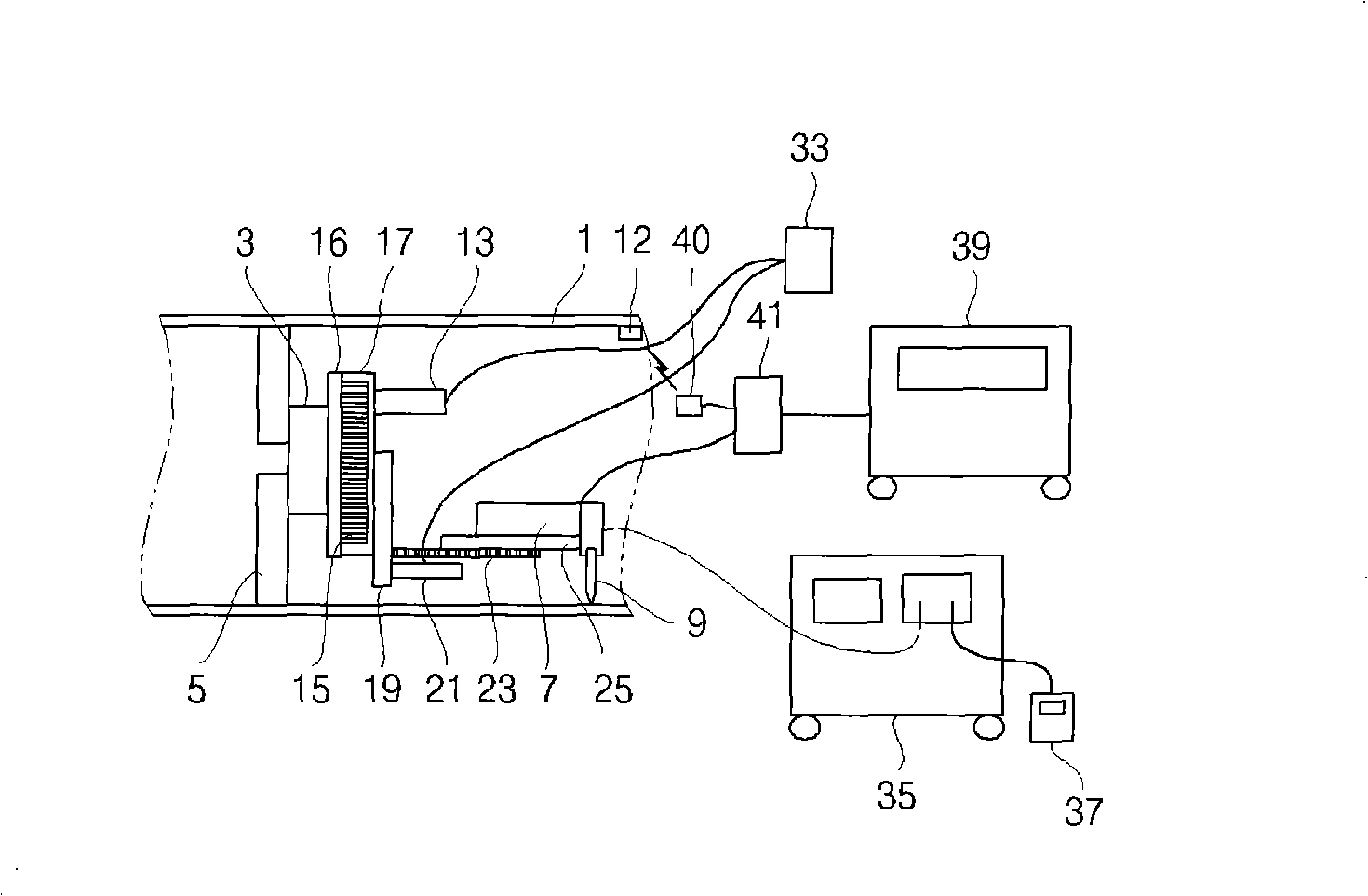

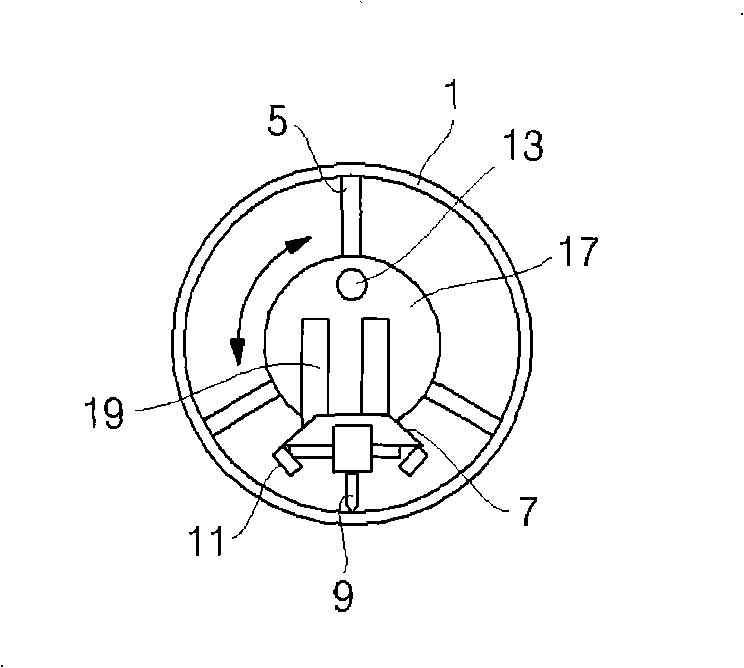

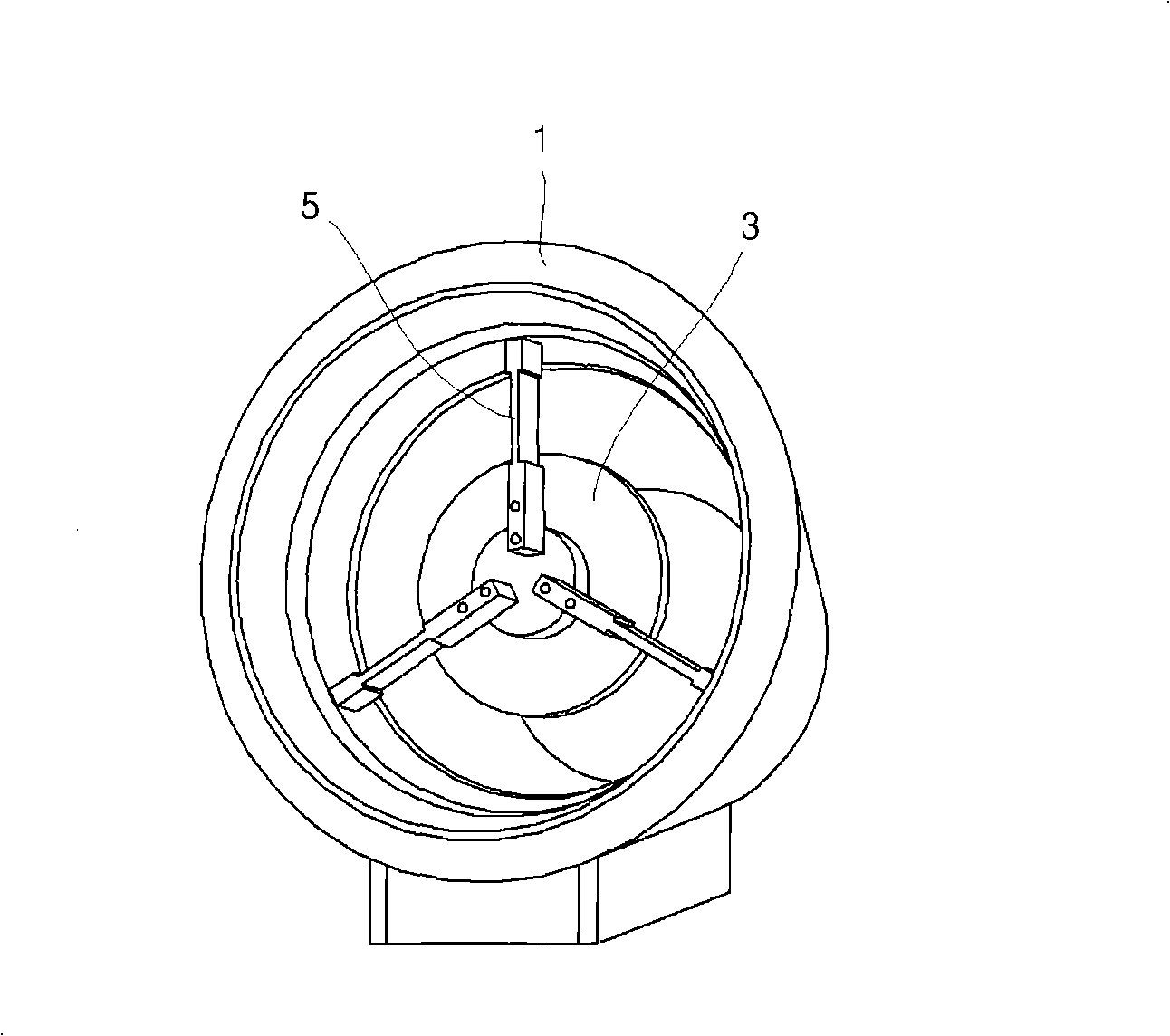

[0029] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings.

[0030] refer to Figure 1 to Figure 6 According to an embodiment of the present invention, the structure of the welding head conveying device on the inner surface of the pipe includes: an interlocking chuck 3 used as a main body; The fixed part 5; the rotary drive motor 13 that generates the power required for welding the pipe 1 in the circumferential direction; the rotary drive part 15 that transmits the power of the rotary drive motor 13 to the rotary cover 17; protects the rotary drive part 15 and uses The conveying device in the longitudinal direction is installed in a manner that is formed, and the rotating cover 17 that rotates along the circumferential direction of the pipe 1 is transmitted from the above-mentioned rotating drive part 15; the rotating part mounting rod 19 connected to the above-mentioned rotating cover 17; The front and rear conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com