Viscous fan drive systems having fill and scavenge control

A technology of fluid flow and studio, applied in the direction of transportation and packaging, engine components, engine cooling, etc., can solve the problems of impact, fan drive regulation robustness limitation, fan driver lack of active control of viscous fluid, etc., to achieve regulation robustness short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

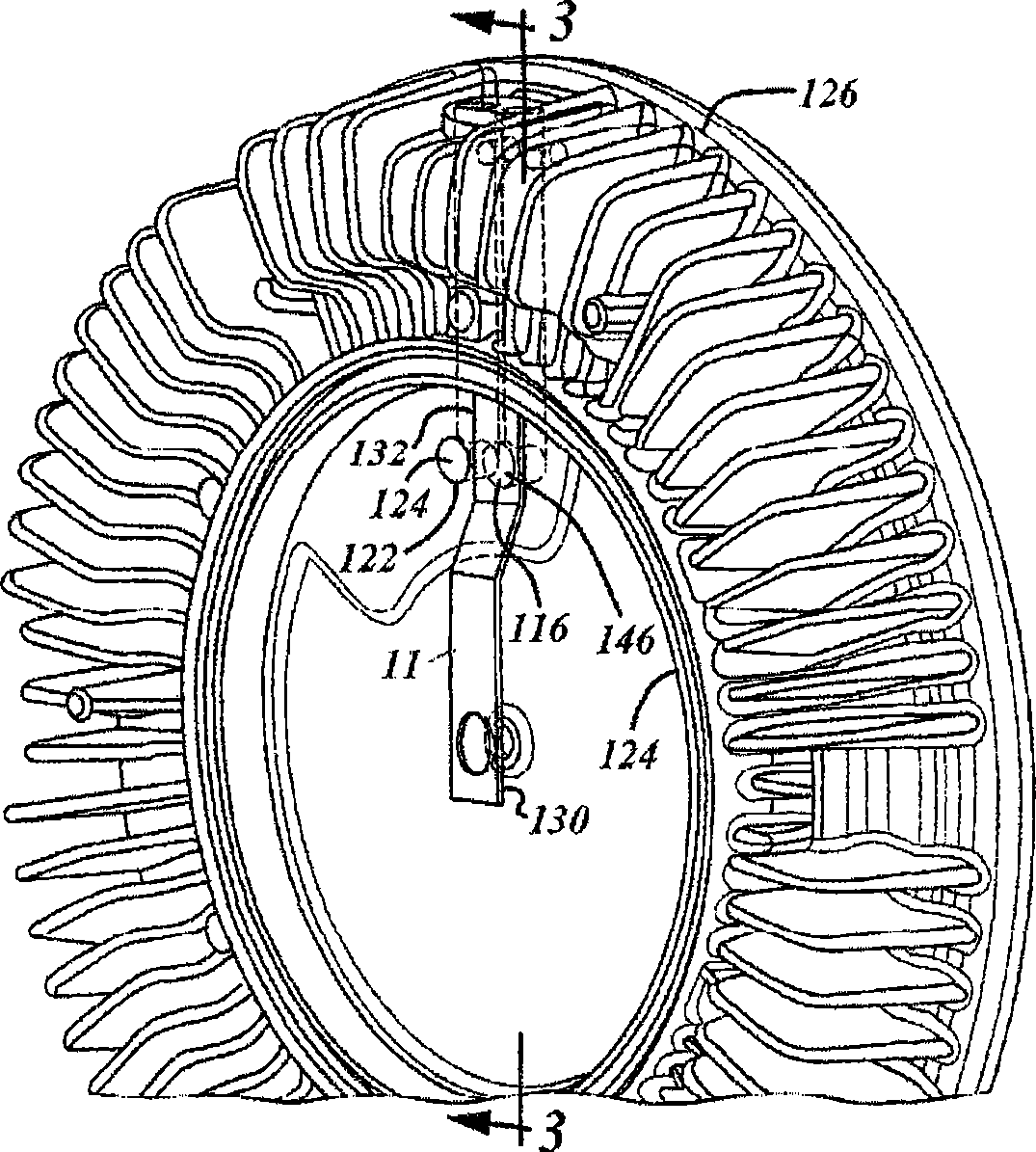

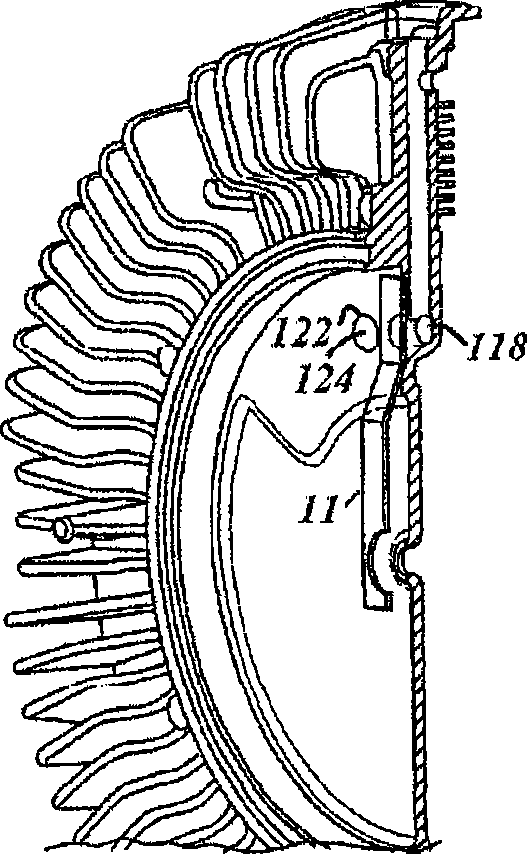

[0026] In the following figures, the same reference numerals will be used to refer to the same components. Although the invention can be advantageously used in clutch arrangements having different configurations and uses, it is particularly advantageous for use in an electronically and / or mechanically controlled fluid connection of the type used to drive a radiator cooling fan of an internal combustion engine. Although the fluid connection device of the present invention is described in connection with a cooling fan for simplicity, it should be understood that the present invention is not limited to these applications and configurations.

[0027] Furthermore, various other embodiments are contemplated having different combinations of the features of the invention described below, having some features other than those described herein, or even lacking one or more of these features. As such, it should be understood that the invention may be implemented in other and different sui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com