Relief valve for fuel supply system and method for manufacturing such a valve

A fuel supply system, overflow valve technology, applied in the direction of the charging system, pumping device components for elastic fluid, liquid fuel feeder, etc., can solve the problem of expensive mechanical chip removal operations, long processing time, waste Material and other issues, to achieve the effects of reduced leakage, prevention of accumulation, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

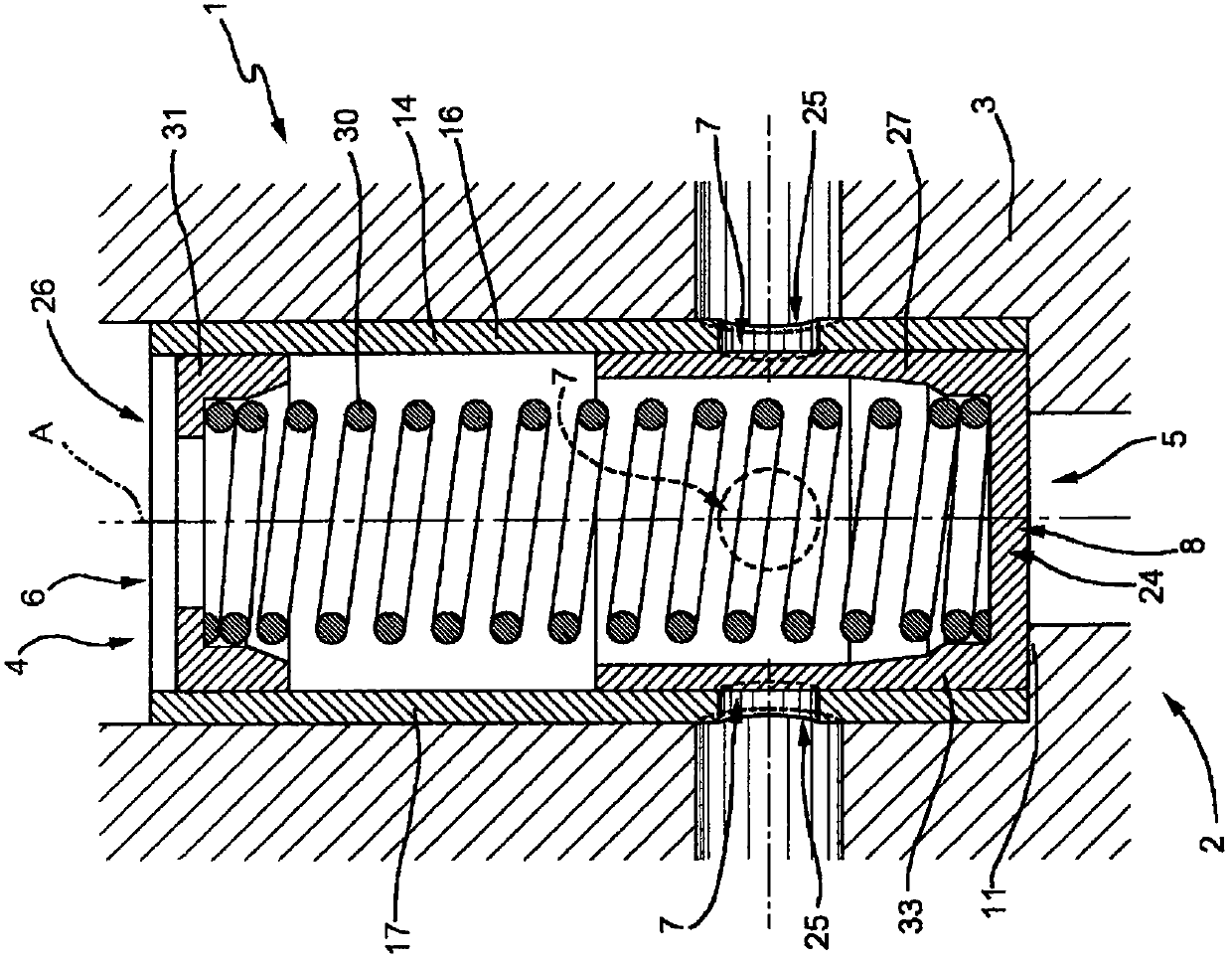

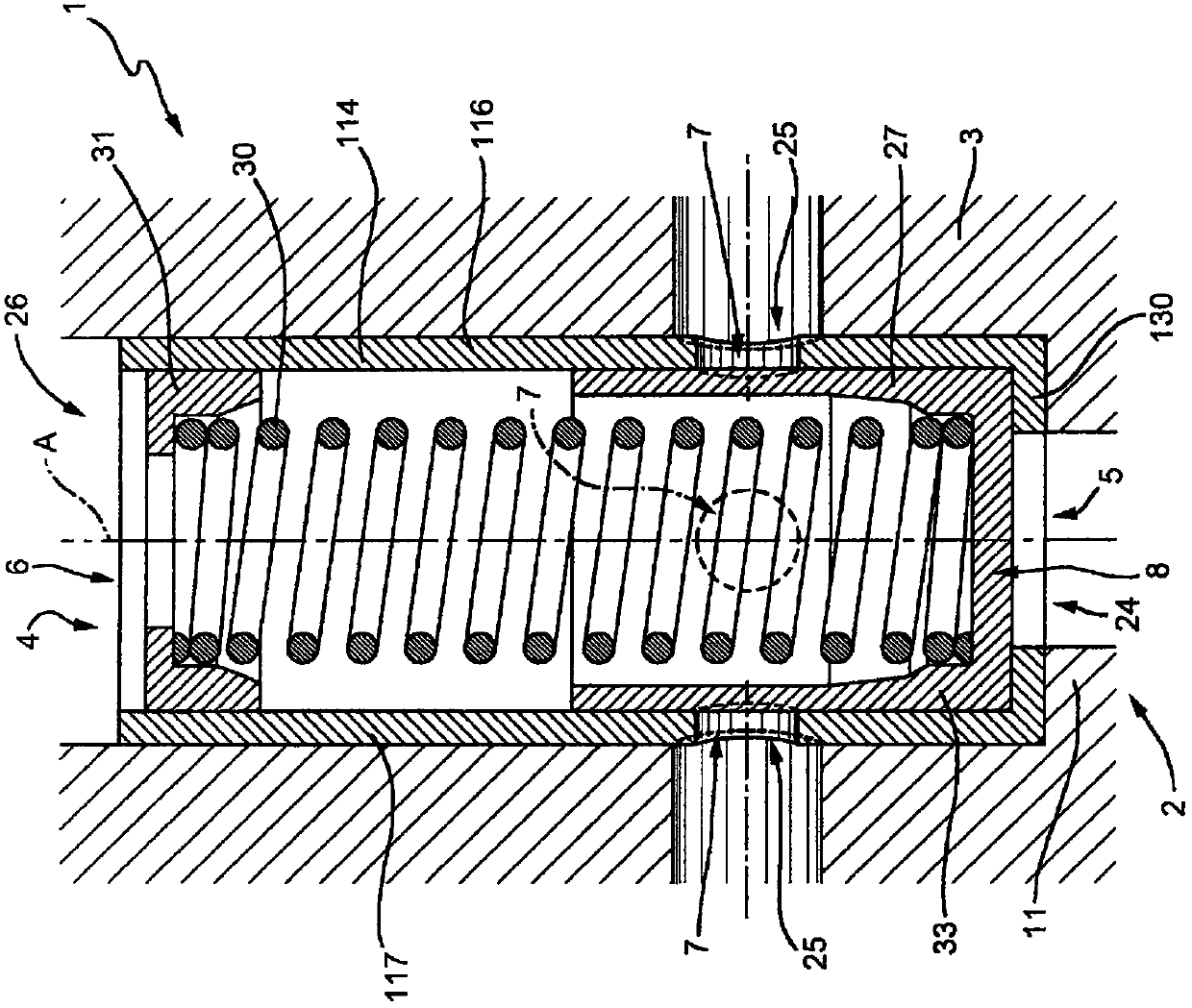

[0040] refer to figure 1 , 1 denotes the entire system for supplying fuel, preferably diesel fuel, from a reservoir (not shown) to an internal combustion engine (not shown).

[0041] The system 1 comprises: a high pressure pump 2 (only partially visible) having a pump body 3 and a seat 4 formed in the pump body 3 ; an inlet duct 5 ; a lubrication duct 6 ; a discharge duct 7 and an overflow valve 8 . An inlet duct 5 , a lubricating duct 6 and a discharge duct 7 are formed in the pump body 3 . Furthermore, the pump body 3 comprises an annular wall 11 protruding at one end of the seat 4 .

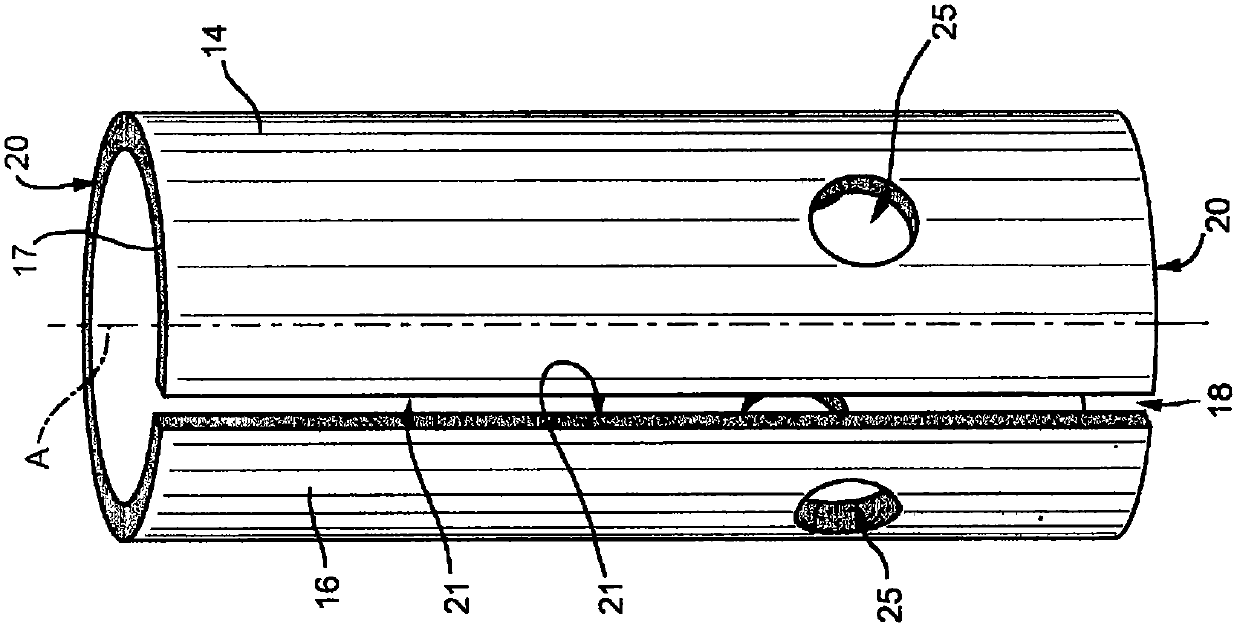

[0042] refer to figure 1 and figure 2 The overflow valve 8 comprises a valve body 14 formed by a metal plate 16 bent at least partially in the form of a cylindrical wall 17 . In more detail, the valve body 14 is a cylinder with a slot 18 along the generatrix of said cylinder. The slot 18 extends along the entire length of the cylinder. In fact, the unfolded metal sheet 16 comprises two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com