Global nonlinear inductance test method of switched reluctance motor

A technology of switched reluctance motor and test method, which is applied in the direction of motor generator test, measurement of resistance/reactance/impedance, measurement device, etc., can solve the problem of large inductance error of switched reluctance motor, and achieves simple measurement method and measurement accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

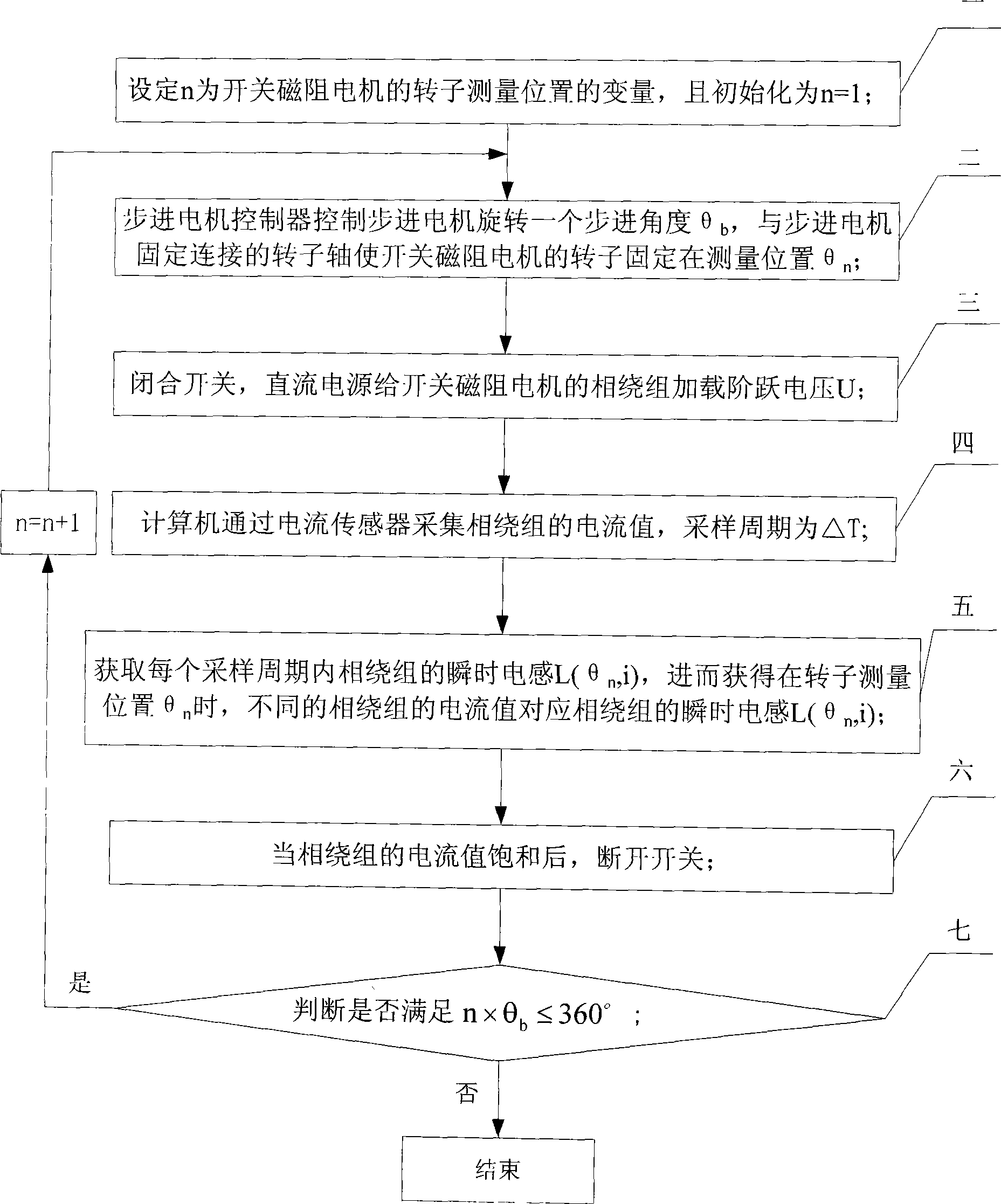

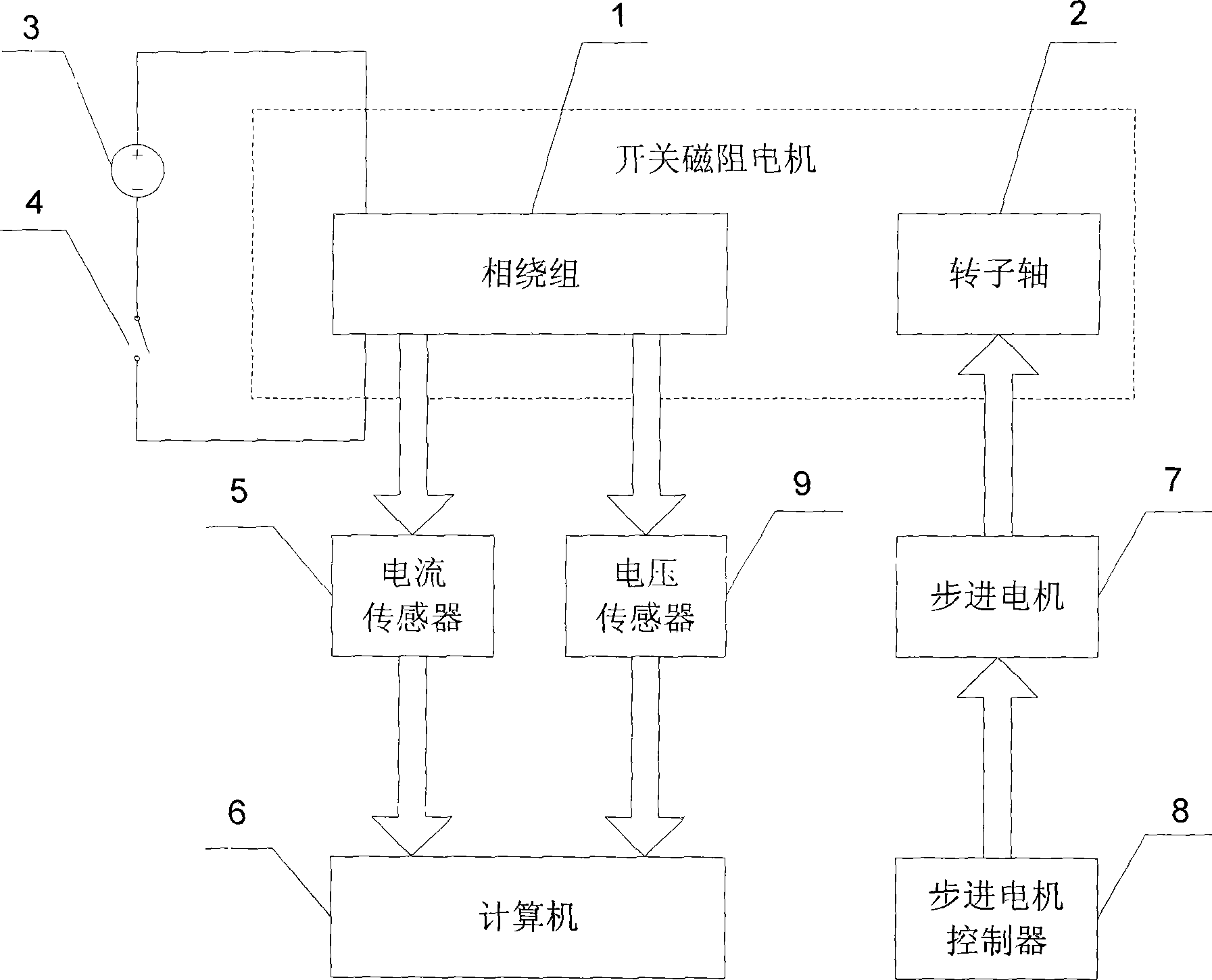

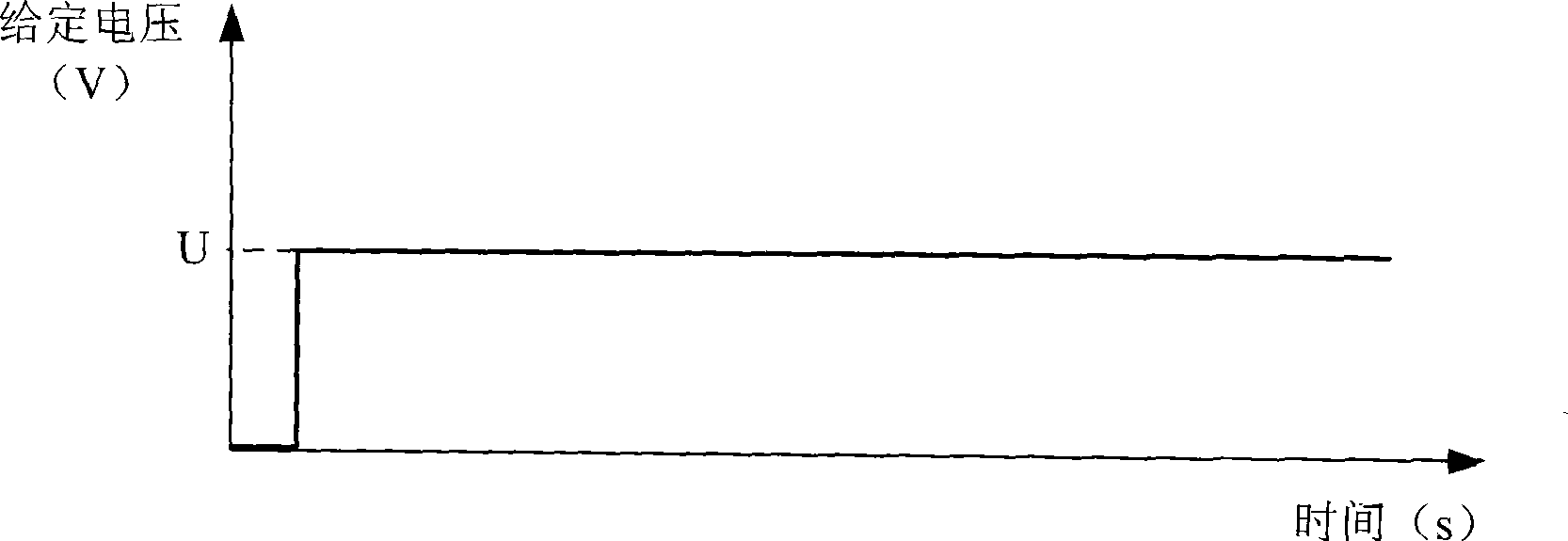

specific Embodiment approach 1

[0022] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the device used in the method of this embodiment includes a switched reluctance motor, a DC power supply 3, a switch 4, a current sensor 5, a computer 6, a stepper motor 7 and a stepper motor controller 8, and the phase of the switched reluctance motor The positive input terminal of the power supply of the winding 1 is connected to the positive terminal of the DC power supply 3, the negative terminal of the DC power supply 3 is connected to one end of the switch 4, and the other end of the switch 4 is connected to the negative input terminal of the power supply of the phase winding 1,

[0023] The current sensor 5 collects the current of the phase winding 1 and outputs it to the computer 6,

[0024] The output terminal of the stepper motor controller 8 is connected with the control terminal of the stepper motor 7, and the output shaft of the stepper motor 7 is fix...

specific Embodiment approach 2

[0056] Embodiment 2: The difference between this embodiment and Embodiment 1 is that it also includes a voltage sensor 9, which collects the voltage of the phase winding 1 and outputs it to the computer 6. Others are the same as Embodiment 1.

[0057] The voltage sensor 9 monitors whether the voltage value loaded on both ends of the phase winding 1 is normal.

specific Embodiment approach 3

[0058] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the step voltage U=1.2I described in step 3 e R, where I e R is the rated current of the phase winding 1, R is the equivalent resistance of the phase winding 1, and the others are the same as the first embodiment.

[0059] It is better to set the voltage value loaded on both ends of the phase winding 1 in this way, and the motor will not be burned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com