Turbulent and boiling combined-circulation fluidized bed refuse incinerator

A waste incinerator and combined cycle technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of unstable temperature of incinerators, insufficient combustion, and reduced blending ratio, so as to increase daily processing capacity and save Energy, the effect of alleviating high temperature slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

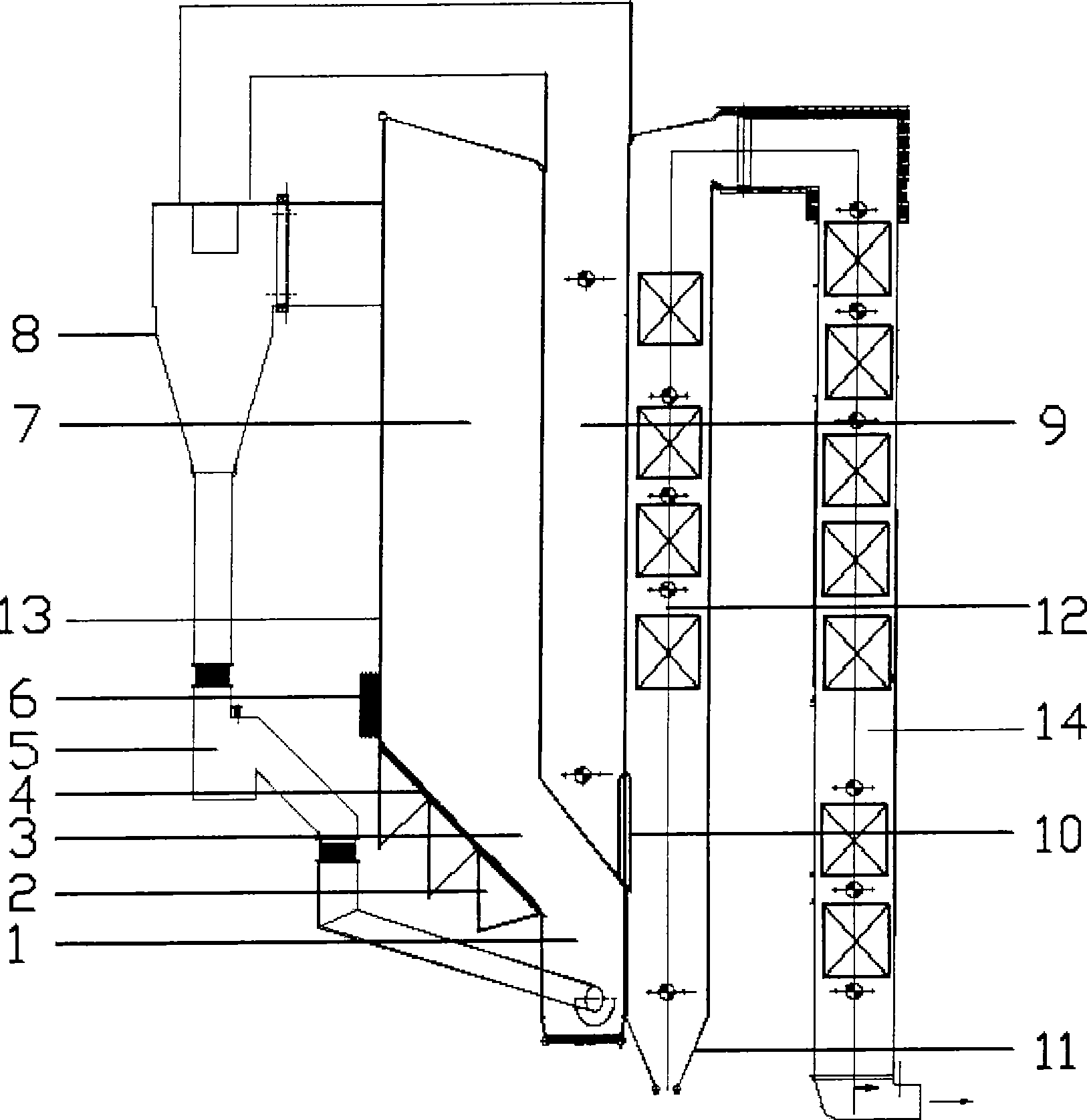

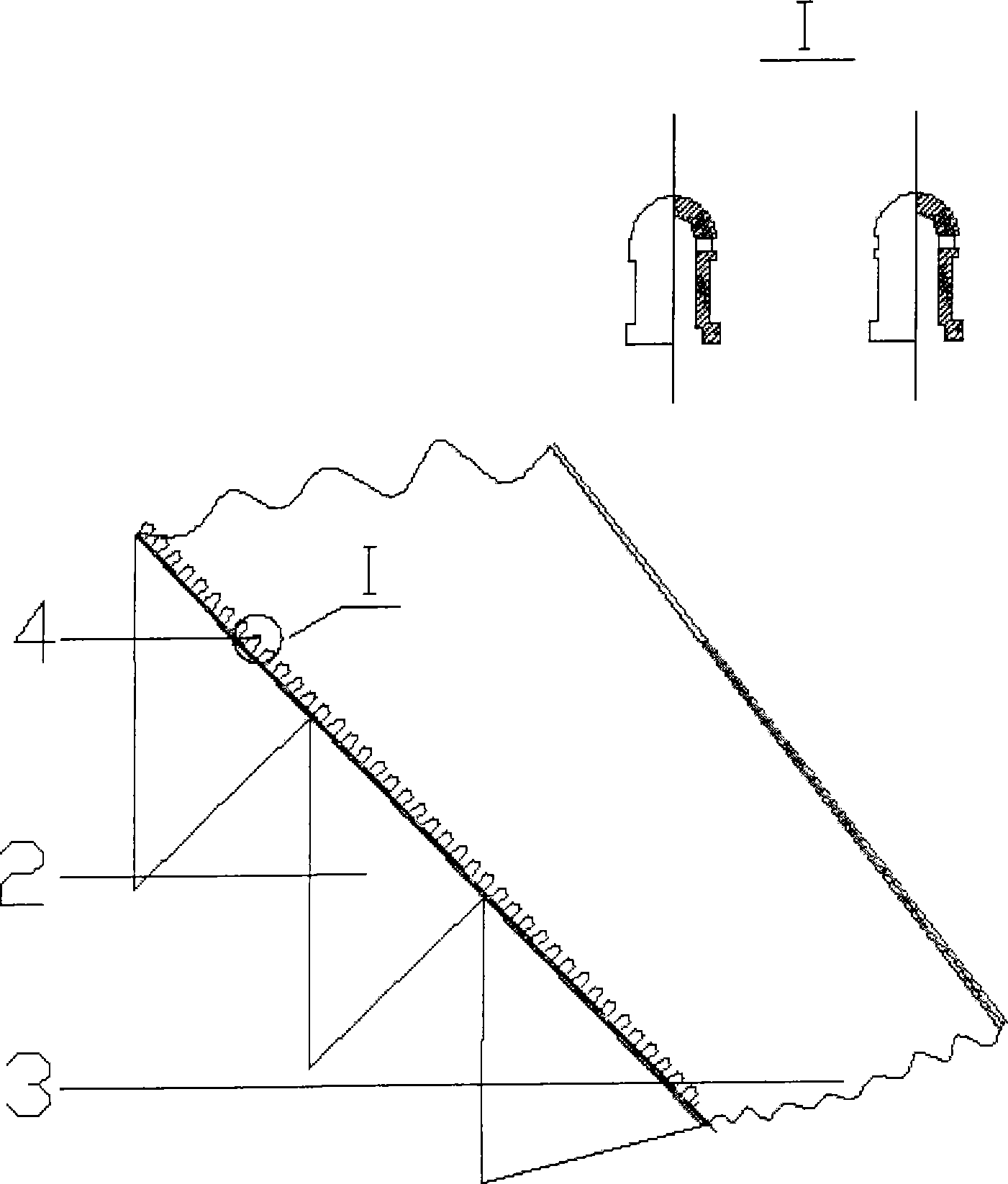

[0015] like figure 1 and figure 2 The shown turbulent compound circulating fluidized bed garbage incinerator includes a furnace 13 and a cyclone separator 8. The lower part of the furnace 13 is provided with a boiling chamber 1. The boiling chamber 1 is provided with a fluidized bed. A garbage inlet is opened in the middle of the furnace 13. There is a turbulence chamber 3 between the feed port 6, the waste feed port 6 and the boiling chamber 1, which can make the waste be transferred obliquely. The turbulence chamber 3 includes an air distribution plate. Chamber hood. The lower part of the turbulence chamber 3 is provided with three air chambers 2 arranged equidistantly.

[0016] The upper part of the furnace 13 is connected with the cyclone separator 8, the lower part of the cyclone separator 8 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com