Torque motor actuator of rotary diesel engine

A torque motor and diesel engine technology, which is applied in the field of marine diesel engine position control electronic speed control actuators, can solve the problems of low reliability, poor linearity of the rotation angle sensor, and inability to directly feed back the displacement of the diesel engine fuel injection pump rack, etc. Fast, reliable control of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0020] Firstly, the working principle of the diesel engine position control speed regulation mode is analyzed. The control of the speed of the diesel engine is realized by controlling the fuel injection quantity of the fuel injection pump, and the control of the fuel injection quantity is realized by adjusting the position of the fuel injection pump rack. The output of the speed control actuator is generally directly connected to the rack. The electronic speed control of the diesel engine position control is to control the displacement of the speed control actuator output by collecting information such as the speed, exhaust, and oil temperature of the diesel engine, and feedback it through the position sensor. Output displacement.

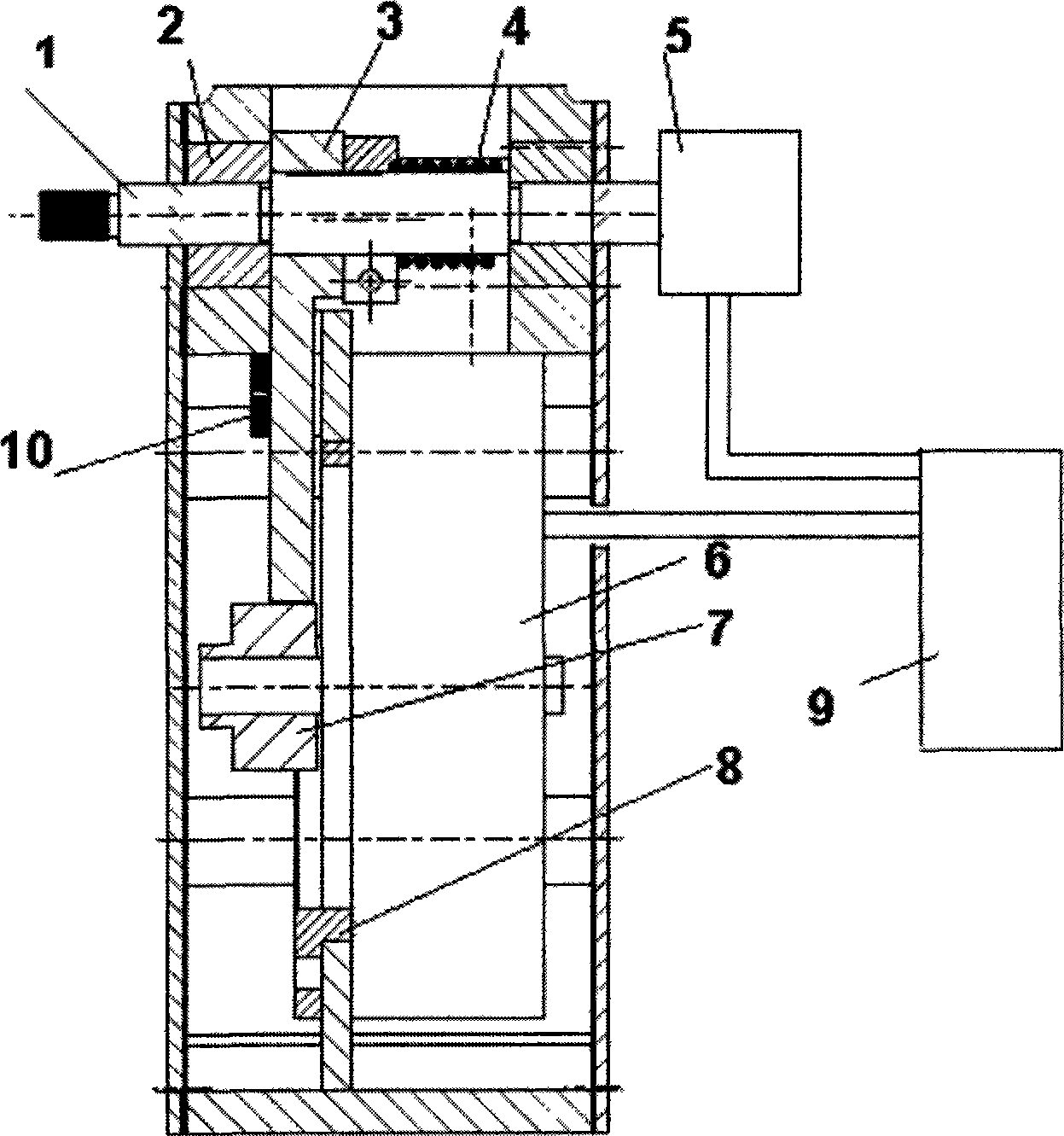

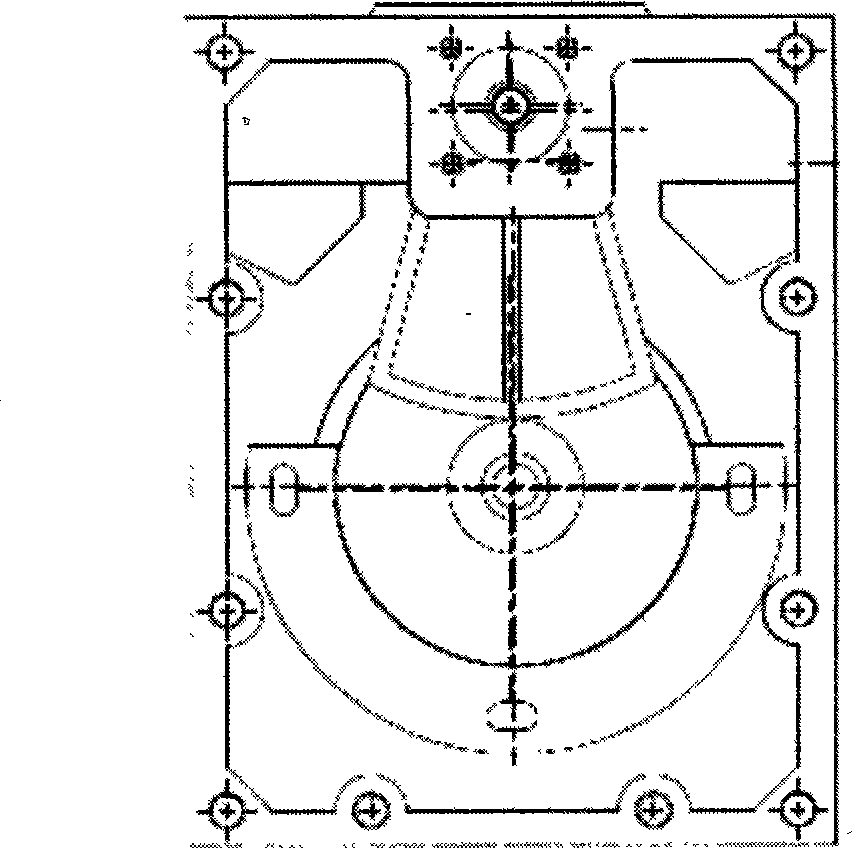

[0021] In order to realize the purpose of the speed regulating actuator, the torque motor actuator of the rotary diesel engine of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com