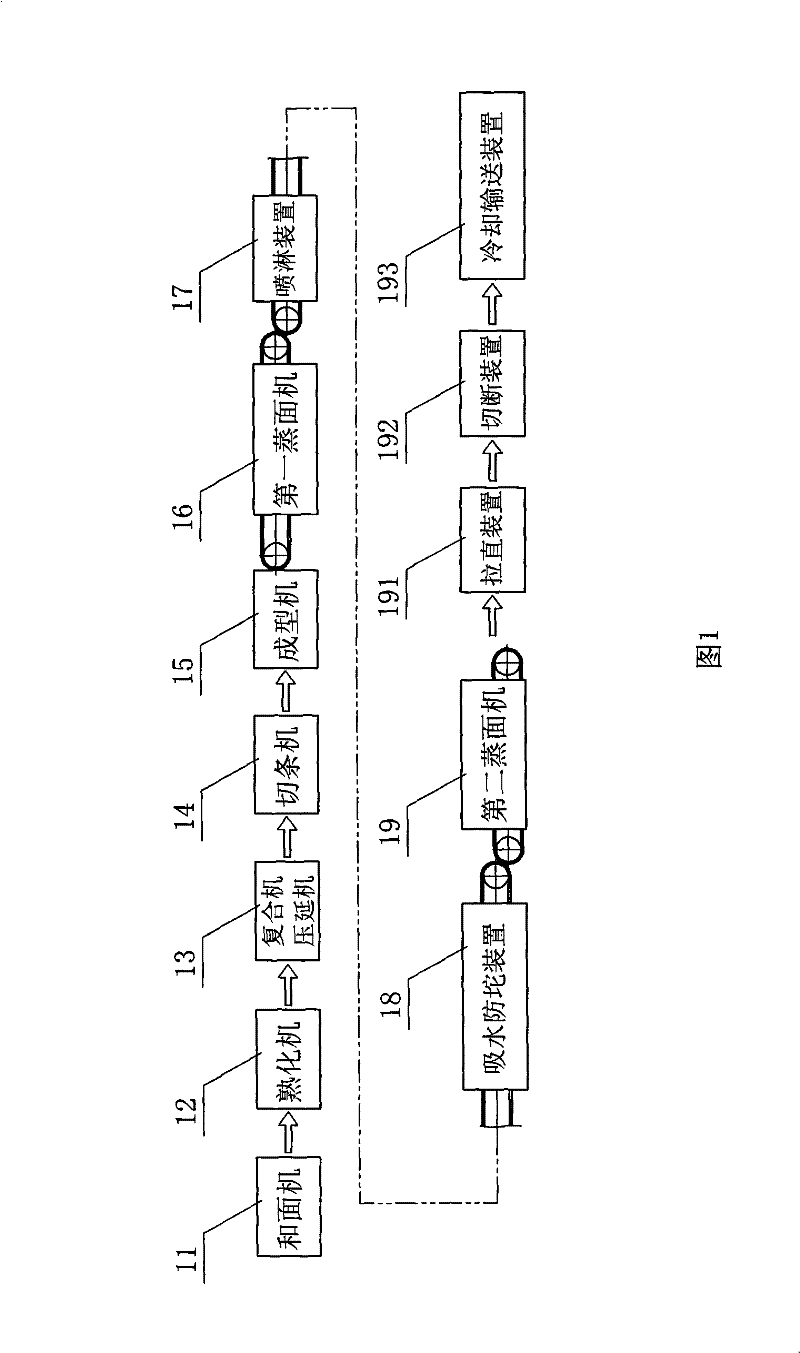

Steamed noodle production line and noodle steaming machine thereof

A noodle steamer and production line technology, applied in the fields of dough processing, baking, food science, etc., can solve the problems of reduced water content of noodles, hardened noodles, affecting the taste and tendon of steamed noodles, etc., so as to reduce gasification and water content. High, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

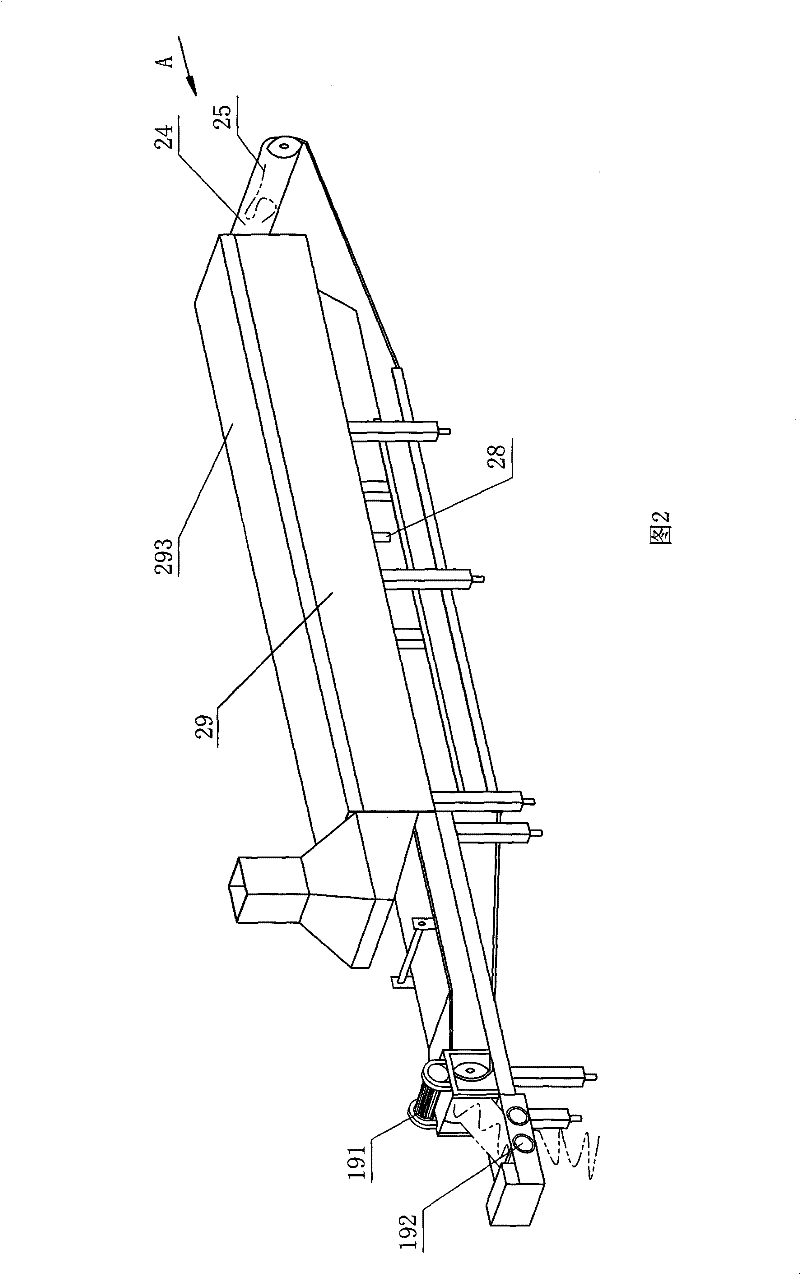

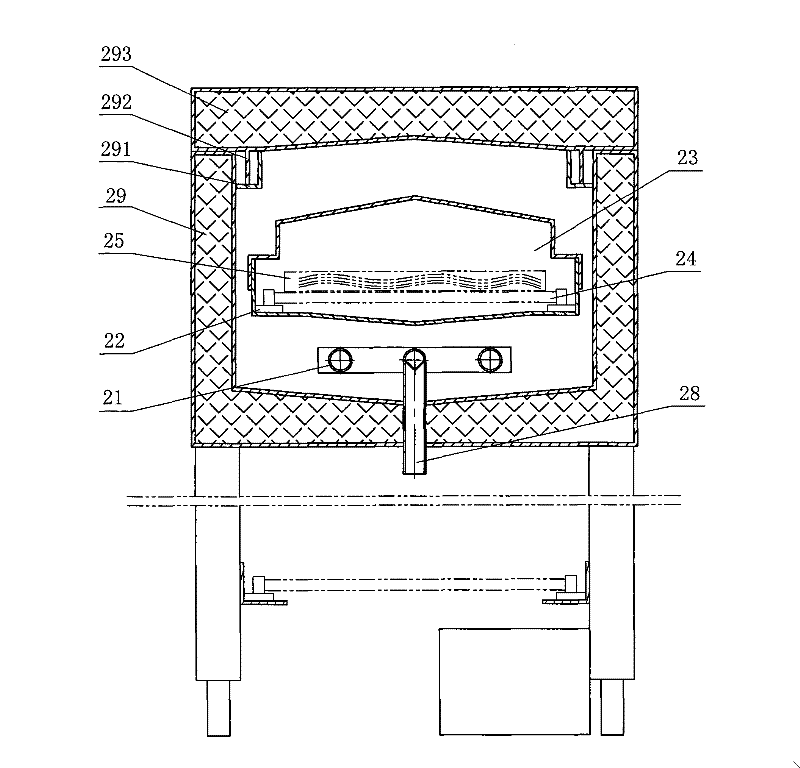

[0035] like Figure 2-7The noodle steamer shown is the first embodiment provided by the present invention, and the noodle steamer includes a steamer and a steam injection pipeline 21 and an inner container arranged in the steamer, and both ends of the inner container have a The opening of the mesh belt 24, the inner cavity of the inner bag is a conveying mesh belt transmission channel 23, and the inner wall of the inner bag is provided with a conveying mesh belt guide rail 22, and the conveying mesh belt 24 can convey raw noodles 25 through the conveying mesh belt guide rail 22; The air injection pipeline 21 is positioned at the bottom of the liner, the two ends of the steam injection pipeline 21 are provided with plugs 26, and the air injection holes 27 are spaced above the side of the pipeline wall along the length direction of the pipeline, and the air injection holes 27 on both sides are staggered. , when the intake air from the air intake pipe 28, the steam will be spraye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com