Bulk material handling system and control

A bulk material and processing system technology, applied in the direction of electrical digital data processing, conveyor control devices, digital data processing parts, etc., can solve problems affecting cleaning efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

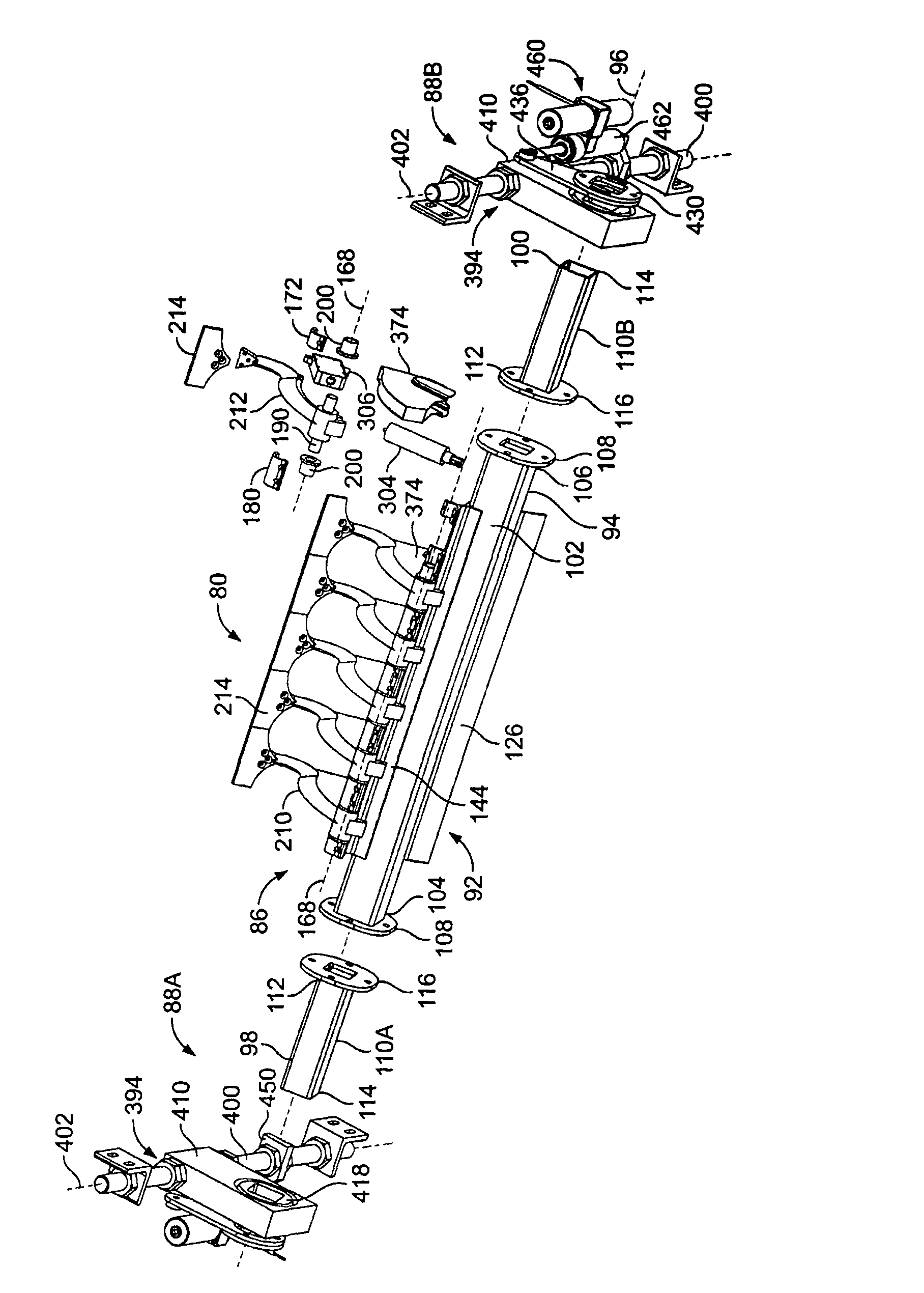

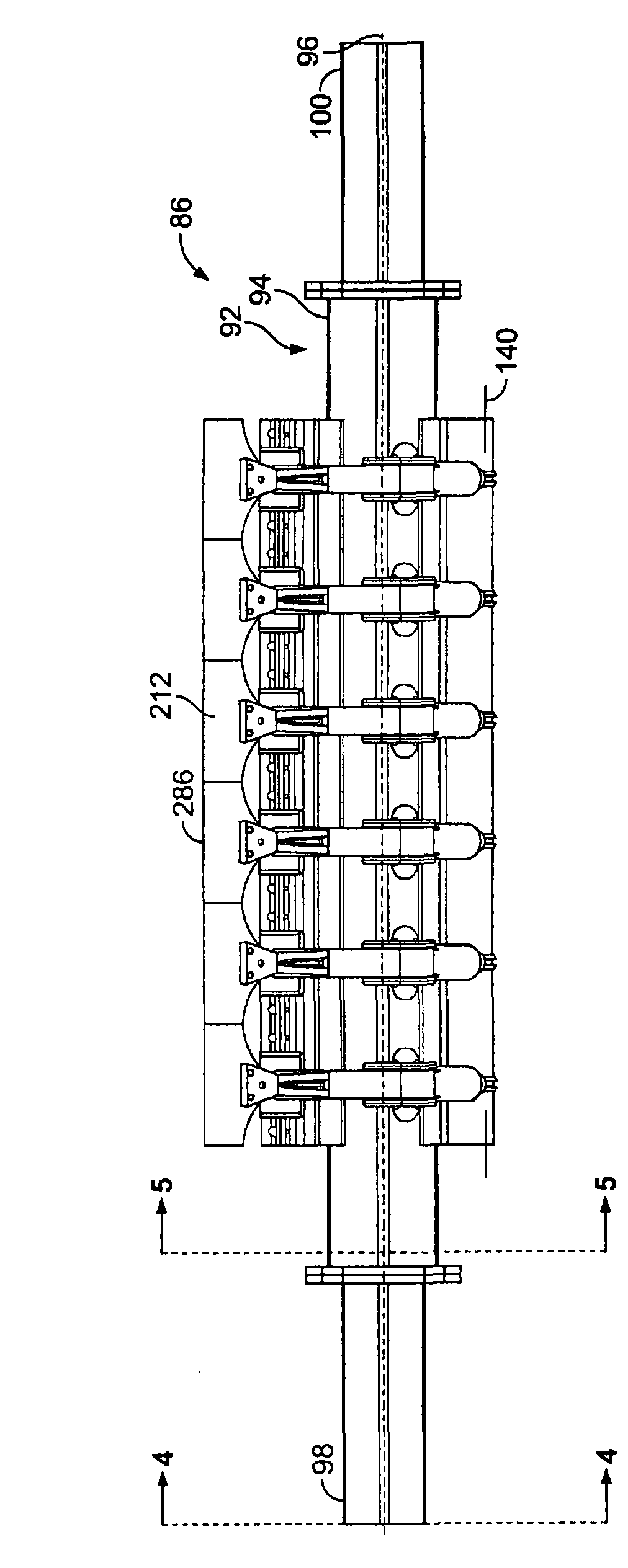

[0092] The following instructions describe techniques for controlling attachments for bulk material handling systems. In the following description, a great deal of specific detail (e.g., logic tools, opcodes, devices used to specify operands; source partitioning / sharing / duplication tools, types and interrelationships of system components, and logical partitioning / integration choices) is For a more complete understanding of the invention. However, it will be understood by those skilled in the art that the present invention may be practiced without these specific details. In other instances, control structures, gate level circuits and entire software instruction sequences have not been shown in detail in order to obscure the invention. Those of ordinary skill in the art will be able to implement the appropriate function from this description without undue experimentation.

[0093] The terms "one embodiment," "an embodiment," "example embodiment," etc. in the specification mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com