Copper coated steel contact wire with high strength, low relaxation and high electric conductivity for electric traction

A technology of electric traction and high conductivity, which is applied in the field of copper-clad steel contact wire with high strength, low relaxation and high conductivity, can solve the problems of short service life, low heat resistance, difficulty in meeting the requirements of high-speed railways, etc., and achieve reduction The effect of reducing construction difficulty, reducing pre-tensioning process, and reducing straightening difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

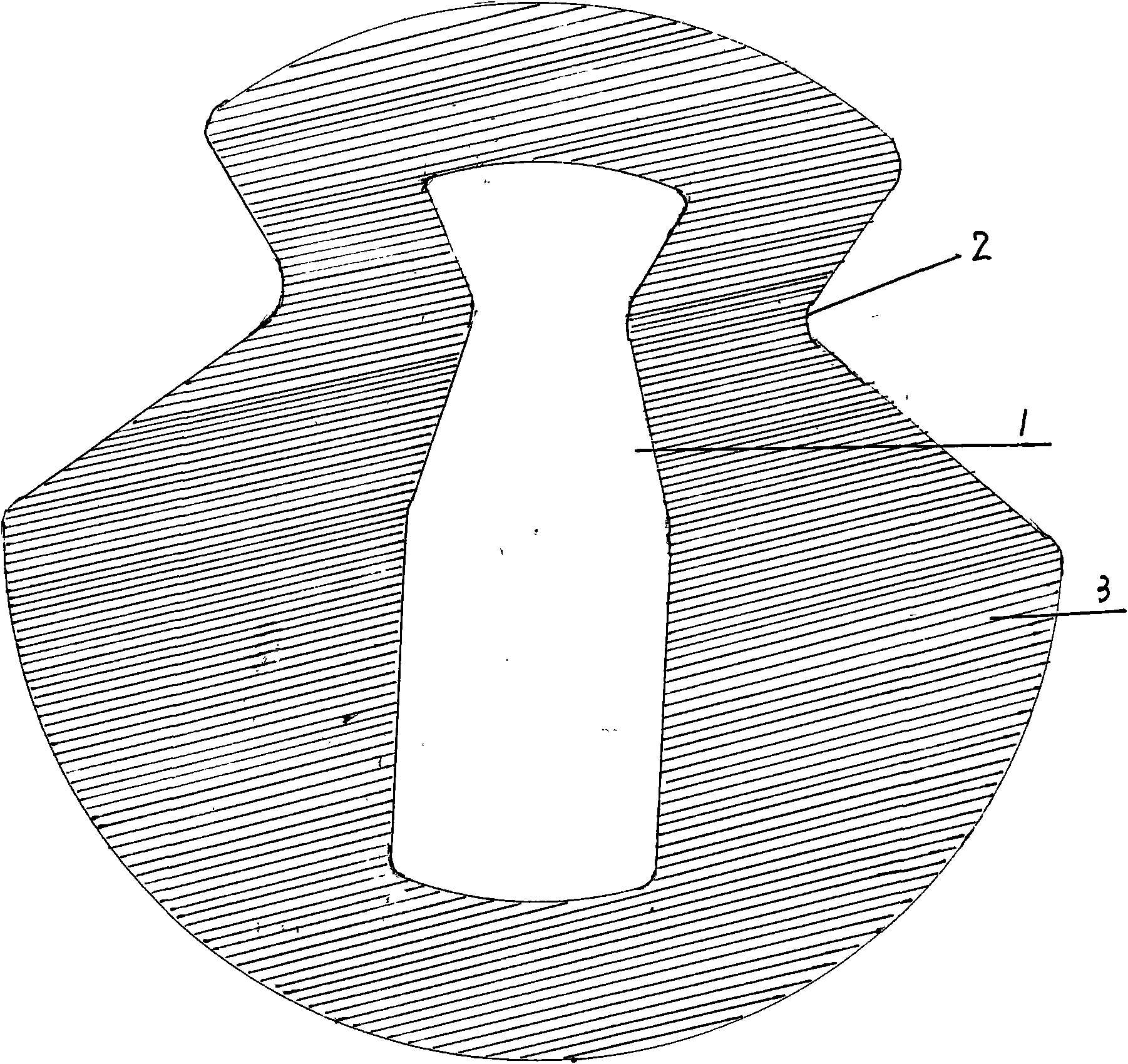

[0017] A high-strength, low-relaxation, high-conductivity copper-clad steel contact wire for electric traction, which wraps copper or copper-silver alloy on a high-strength, low-relaxation steel core, and forms a steel-clad composite contact wire after cold rolling; Tensile strength reaches ≥600 / mm 2 At the same time, the conductivity can reach ≥80% IACS. The tensile strength of the steel core above is ≥1860N / mm 2 , The relaxation rate is ≤2.5% (the initial load is 70% of the tensile strength, and the force loss after 1000 hours is less than or equal to 2.5%). The above-mentioned copper or copper-silver alloy layer accounts for 79%-81% of the sectional area of the contact wire, and the steel core accounts for 19%-21% of the sectional area of the contact wire. The yield strength of the steel core is more than 87% of the tensile strength. It has the high electrical conductivity of copper and the high strength, low relaxation and high yield ratio of steel.

[0018] Such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com