Thread-control high-pressure environment liquid sampler

A high-pressure environment and liquid sampling technology, applied in the direction of sampling devices, etc., can solve the problems of sampling difficulties, inability to effectively inspect and control quality, and inability to truly reflect the quality of polymer dispensing, etc., to achieve simple structure and prevent shearing , the effect of convenient sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The experimental methods in the following examples are conventional methods unless otherwise specified.

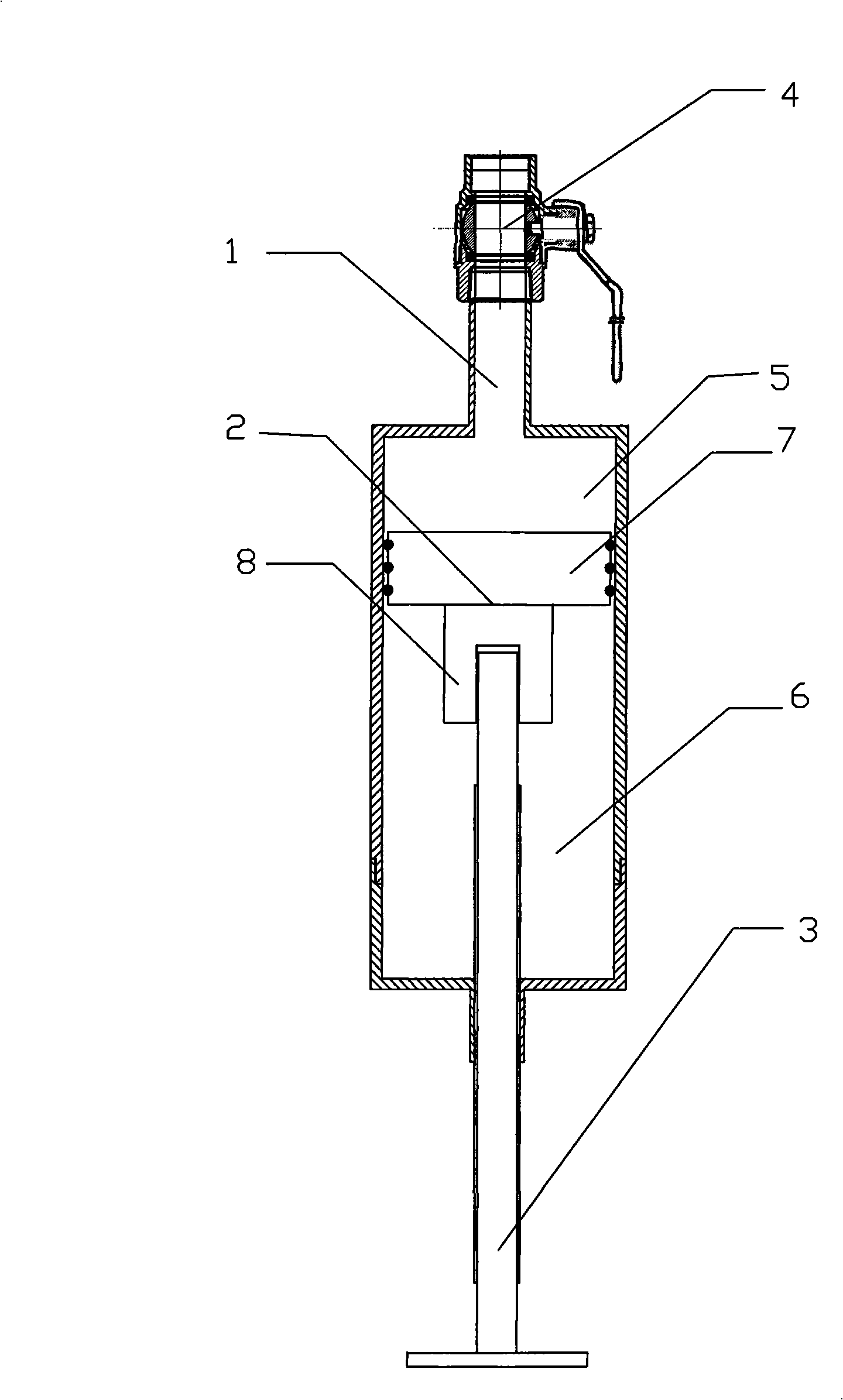

[0014] Such as figure 1 As shown, the thread control type high-pressure environmental liquid sampler of the present invention includes a sealed cylinder composed of a main cavity and a sampling cavity 1 communicating with it, a piston 2 , a push rod 3 and a sampling valve 4 . The piston includes a piston head 7 and a boss 8 arranged on the piston head. The free end of the boss is processed into a circular groove, which forms a clearance fit with the cylindrical push rod. The piston is located in the main cavity, and its outer edge is matched with the inner cavity wall of the main cavity (the piston head is provided with a sealing ring), and the main cavity is divided into an inlet connected with the sampling cavity. The buffer chamber 6 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com