Method for anaerobic ammonia oxidation treatment of low-concentration ammonia nitrogen wastewater

A low-concentration ammonia nitrogen and anaerobic ammonia oxidation technology, applied in the field of ammonia nitrogen wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

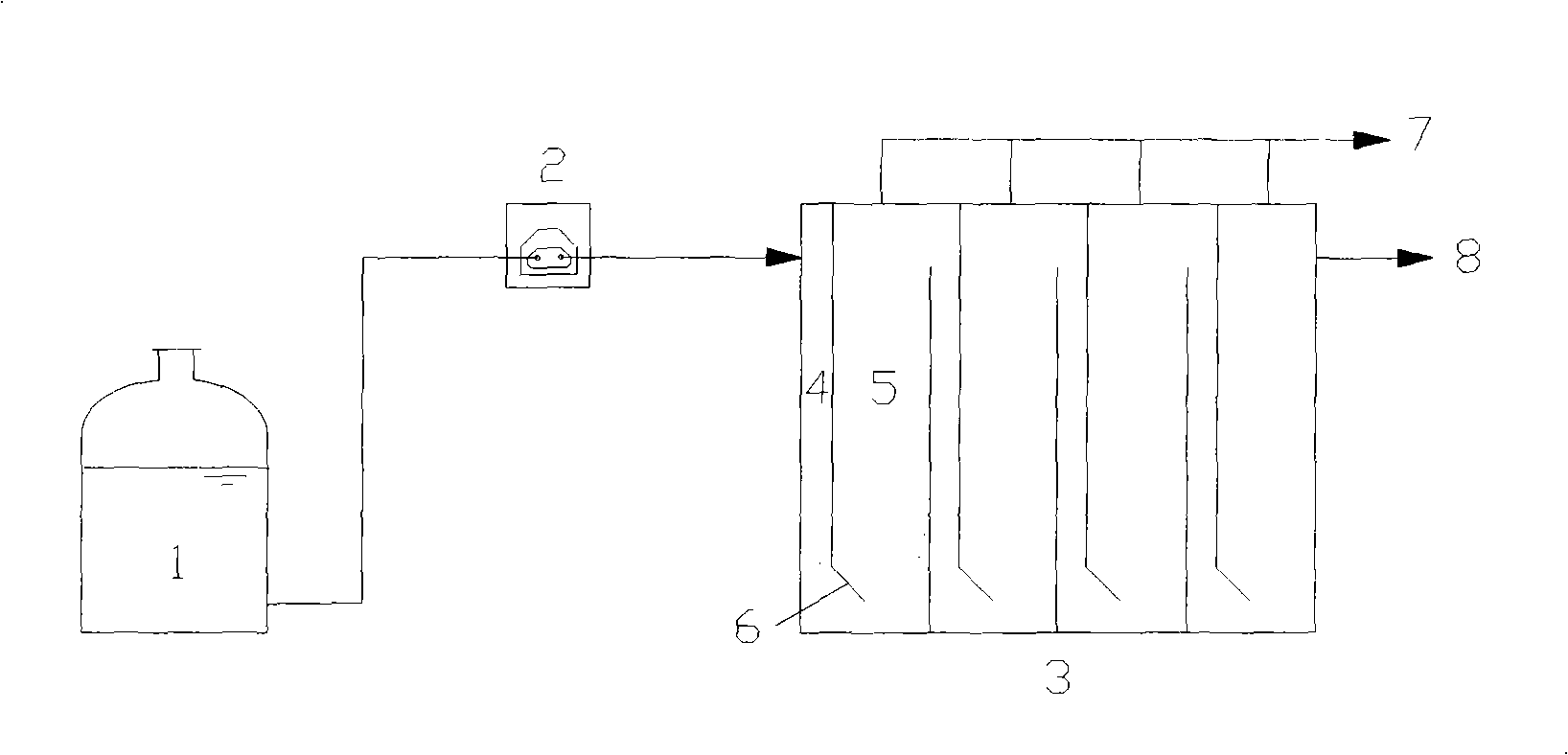

[0016] Inoculate the anaerobic sludge of the landfill leachate treatment plant and river sediment in the anaerobic baffle reactor at a ratio of 3:1, the concentrations of ammonia nitrogen and nitrite nitrogen are both 10mg / L, and the pH is 7.8 (Regulated with hydrochloric acid or sodium hydroxide, the same below) the ammonia nitrogen waste water enters the anaerobic baffle reactor 3 through the water inlet storage bottle 1, controls 0.33L / h with the constant flow peristaltic pump 2 between 1 and 3 The hydraulic retention time of the water is 48h, and the reaction temperature is controlled at 25°C. The treated wastewater is discharged from the water outlet 8, and the biogas is discharged from the exhaust port 7. After 3 months, the anaerobic ammonium oxidation in the anaerobic baffle reactor Bacteria become the dominant flora, and the removal rate of ammonia nitrogen and nitrite nitrogen reaches 80% for 5 consecutive days, indicating that the anaerobic baffled reactor has been s...

Embodiment 2

[0019] Inoculate the anaerobic sludge of the landfill leachate treatment plant and river sediment in the anaerobic baffle reactor at a ratio of 3:1, the concentrations of ammonia nitrogen and nitrite nitrogen are both 20mg / L, and the pH is 8.3 The ammonia nitrogen waste water enters the anaerobic baffle reactor 3 through the water storage bottle 1, and the constant flow peristaltic pump 2 between 1 and 3 is used to control the water volume to 0.33L / h, the hydraulic retention time is 48h, and the reaction temperature is controlled at After 3 months at 30°C, the anammox bacteria become the dominant bacterial group, and the removal rates of ammonia nitrogen and nitrite nitrogen reach 80% for 5 days, which means that the anaerobic baffled reactor has been successfully started;

[0020] After the reactor is successfully started, the ammonia nitrogen wastewater with an ammonia nitrogen concentration of 31.3mg / L, a nitrite nitrogen concentration of 34.9mg / L, and a pH of 8.3 enters 3 t...

Embodiment 3

[0022] Inoculate the anaerobic sludge of the landfill leachate treatment plant and river sediment in the anaerobic baffle reactor at a ratio of 3:1, the concentrations of ammonia nitrogen and nitrite nitrogen are both 15mg / L, and the pH is 8.0 The ammonia nitrogen waste water enters the anaerobic baffle reactor 3 through the water storage bottle 1, and the constant flow peristaltic pump 2 between 1 and 3 is used to control the water volume to 0.33L / h, the hydraulic retention time is 48h, and the reaction temperature is controlled at After 3 months at 28°C, the anammox bacteria became the dominant bacterial group, and the removal rates of ammonia nitrogen and nitrite nitrogen reached 80% for 5 days, indicating that the anaerobic baffled reactor had been successfully started;

[0023] The ammonia nitrogen concentration is 48.7mg / L, the nitrite nitrogen concentration is 49.5mg / L, and the ammonia nitrogen waste water that pH is 8.0 enters the anaerobic baffle reactor 3 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com