Method for evaluating service reliability of numerical control equipment

A reliability and equipment technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of not considering the dynamic changes of reliability, reducing the production efficiency and utilization rate of CNC equipment, and reducing the service reliability of CNC equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

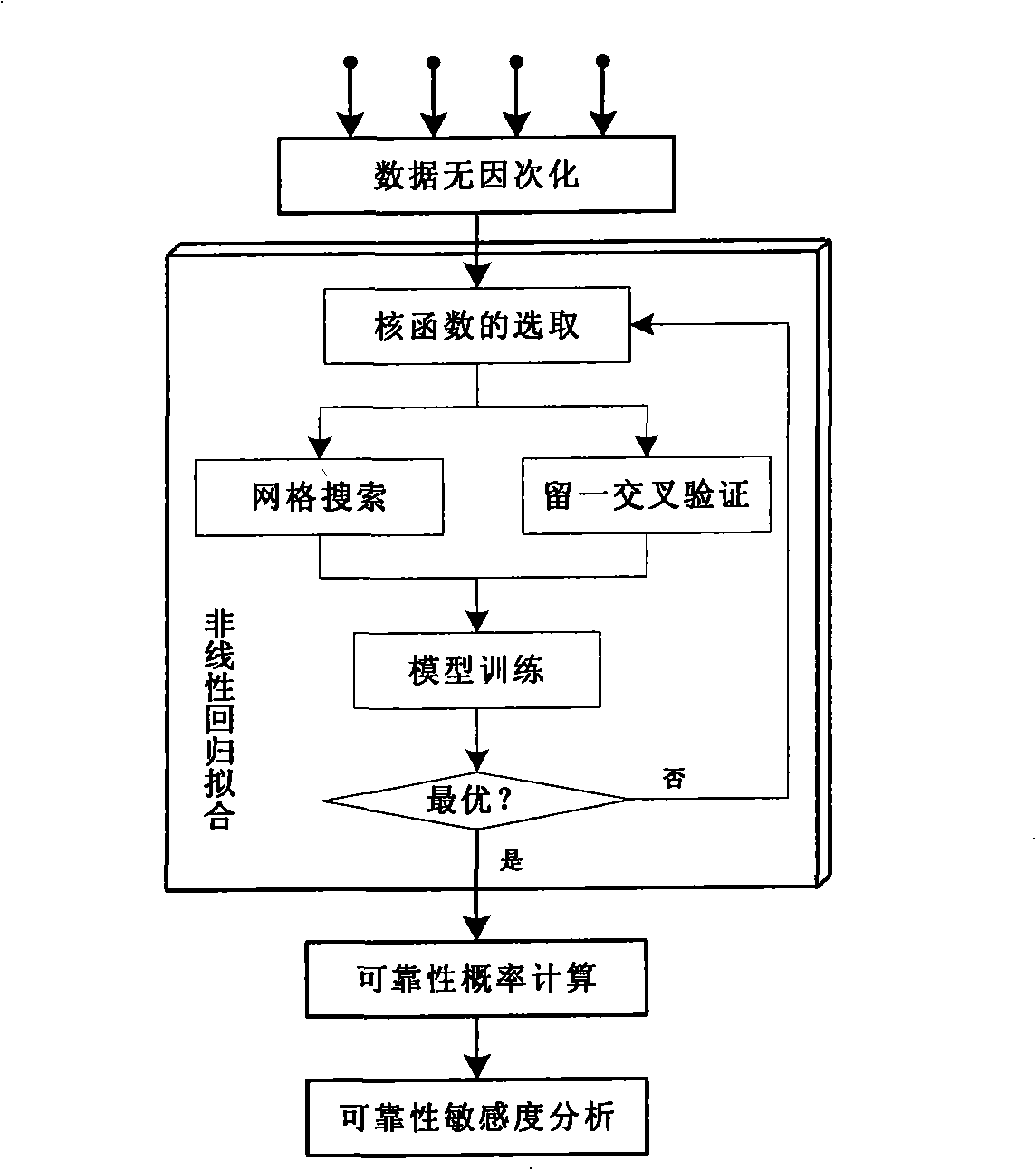

Method used

Image

Examples

Embodiment

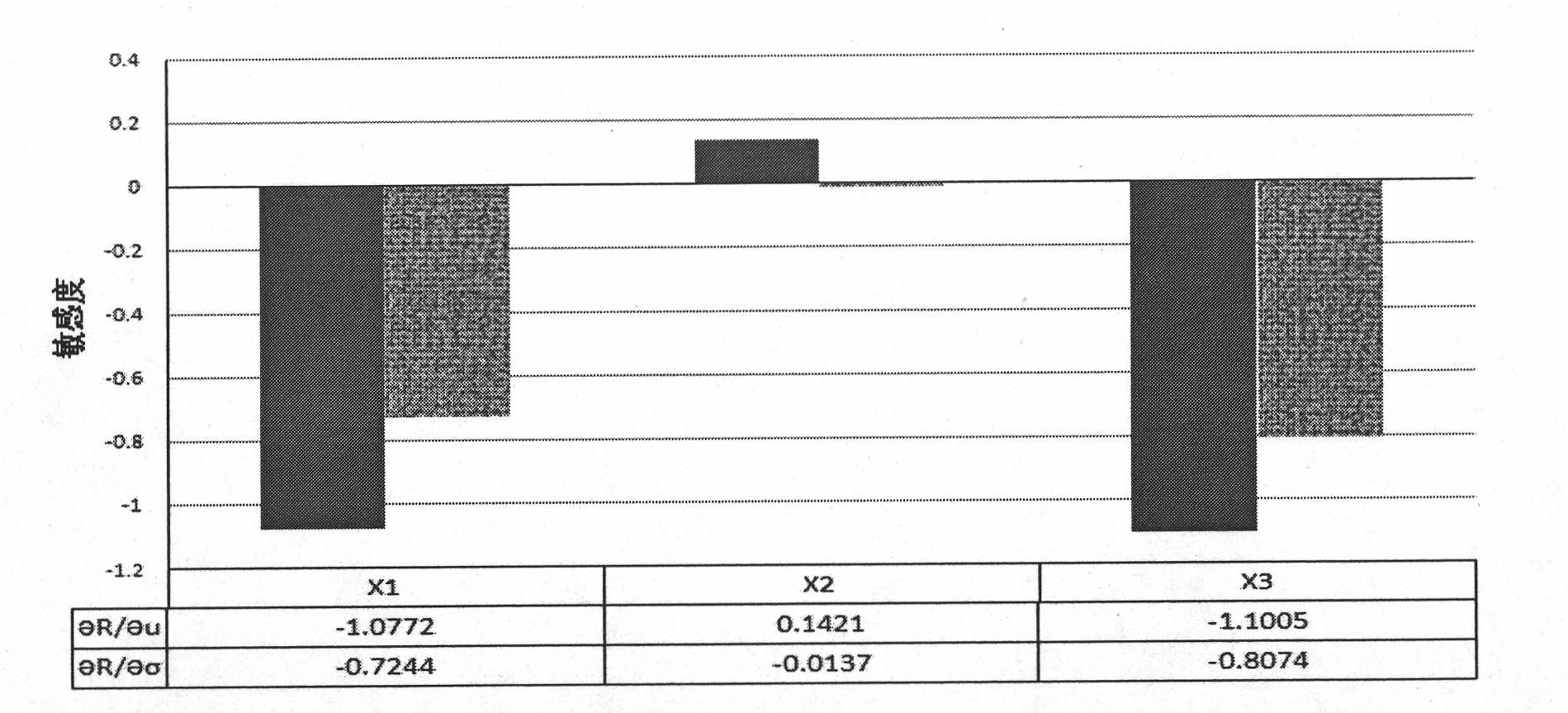

[0057] This embodiment provides a specific implementation process of the present invention in engineering practice, and at the same time verifies the effectiveness of the present invention.

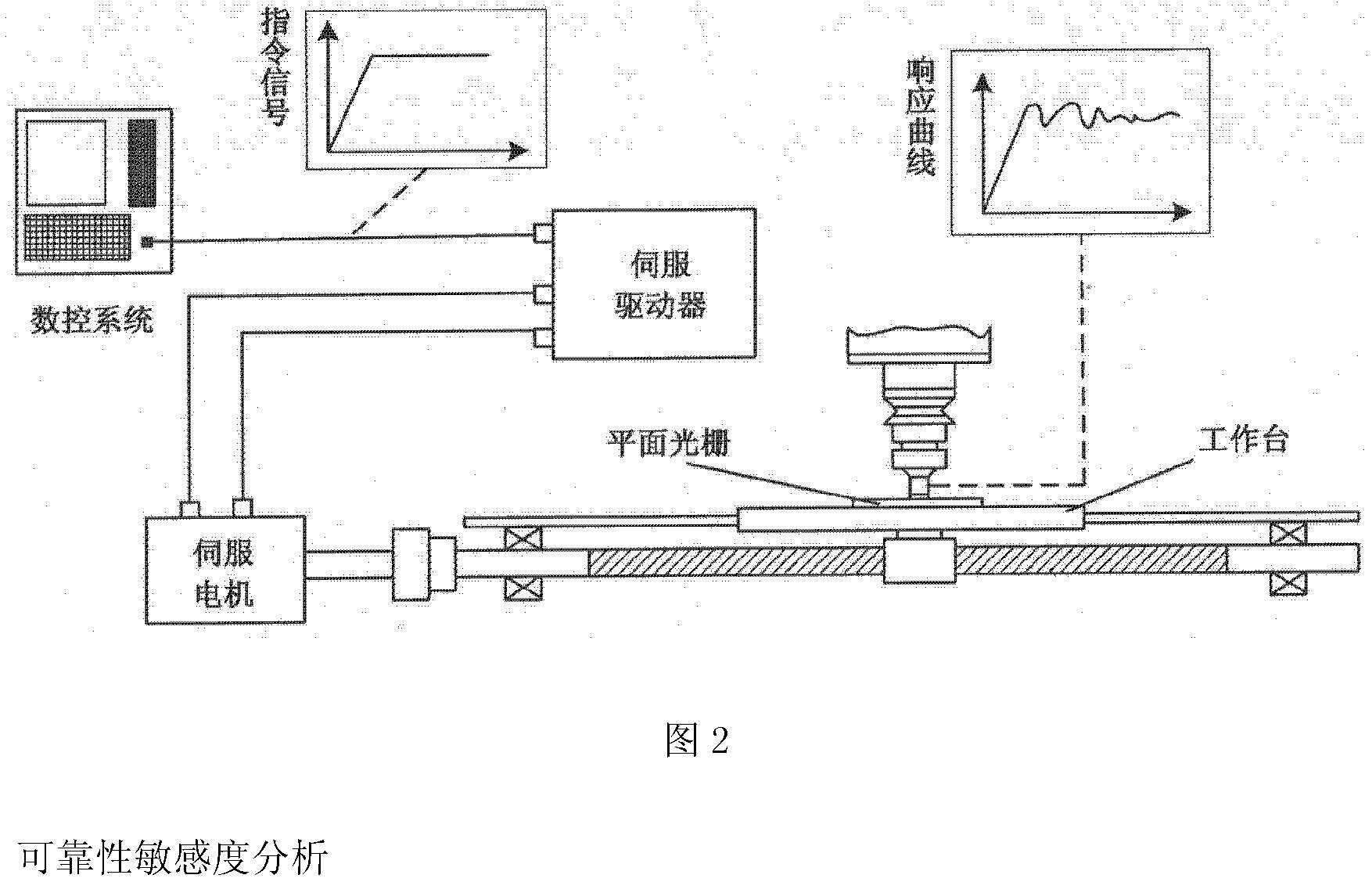

[0058] Reference figure 2 , The feed servo system is an important functional part of CNC equipment and the link between CNC equipment and mechanical transmission parts. The technical indicators such as the motion speed and acceleration, following error, positioning accuracy, and surface quality of CNC equipment depend to a large extent on the feed servo system. However, the feed servo system is constantly affected by various random factors such as external disturbance, vibration, friction, thermal deformation, wear of guide rails and screw nut pairs, and changes in the characteristics of electronic components during the use of CNC equipment, causing its mechanical transmission component parameters (Load quality, rail damping, system stiffness, etc.) and servo drive parameters (position loop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com