Image-based sheet metal deformation measurement and processing method

A processing method and sheet metal technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems that cannot be applied mechanically, cannot be widely used, and cannot meet the requirements of time series measurement, so as to achieve the goal of improving comparability and high guiding significance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

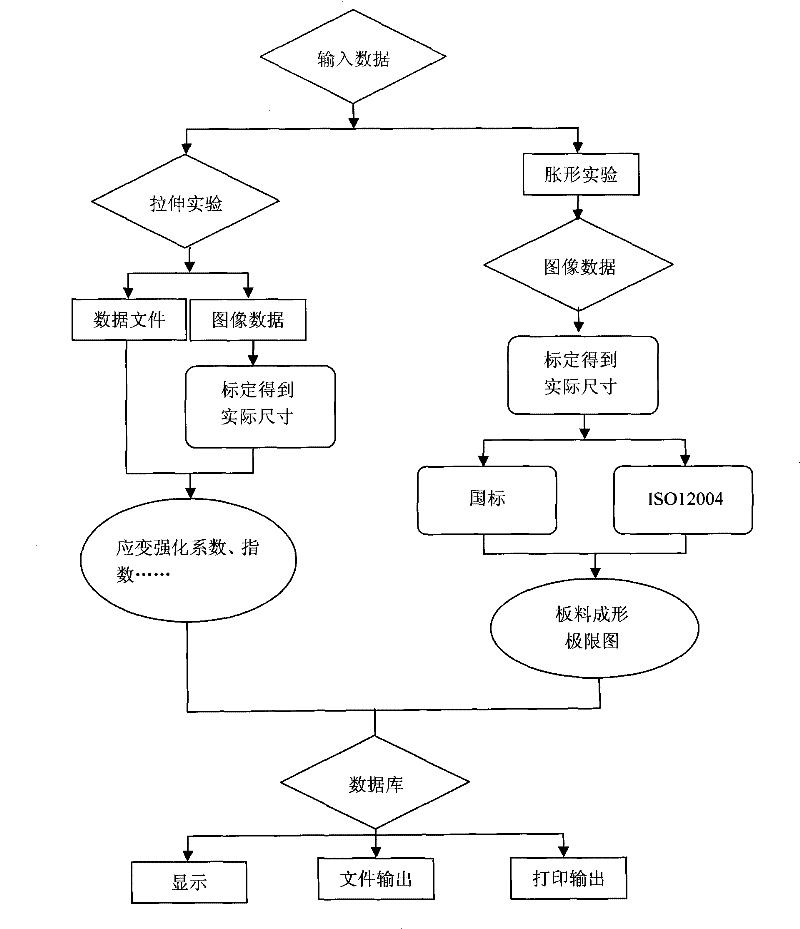

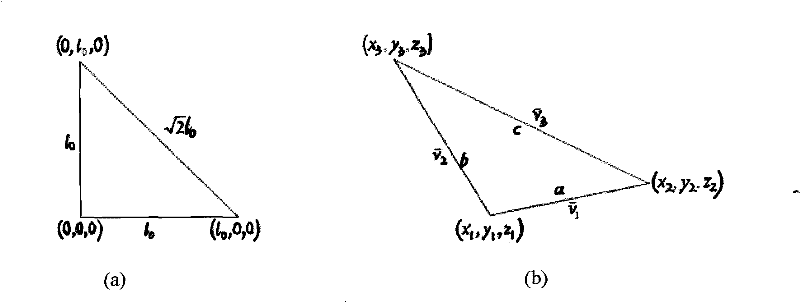

[0026] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

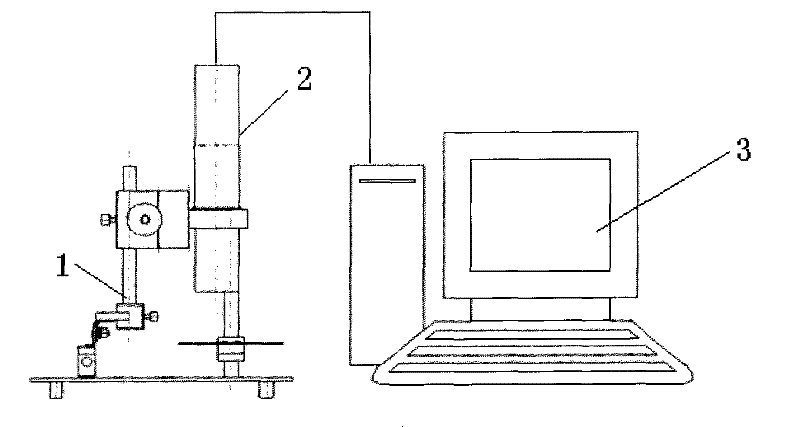

[0027] like figure 1 , figure 2 As shown, the image-based sheet metal deformation measurement processing method adopts a multi-axis rotation and lifting structure 1, a CCD camera and an optical lens 2, and an image and data processing computer 3, wherein the CCD camera and optical lens 2 are set on the multi-axis rotation and lifting On structure 1, the data output end of CCD camera and optical lens 2 is connected to the data input end of image and data processing computer 3, it is characterized in that described measurement processing method comprises the following steps:

[0028] Step 1: Print a grid conforming to the national standard GB / T 15825.8--1995 or ISO12004 on the surface of the sheet;

[0029] The second step: the images of the sheet before and after deformation are taken by the CCD camera and the optical lens and stored in the image and data proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com