Log frame-shaped board and log cabinet formed by the log frame-shaped board

A log and frame-shaped technology, which is applied in the field of cabinets composed of log frame-shaped panels, can solve the problems of high manufacturing cost, inability to enter ordinary people's homes, and no rapid assembly, so as to reduce transportation costs and damage rates, reduce Warehouse loss, easy disassembly and assembly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

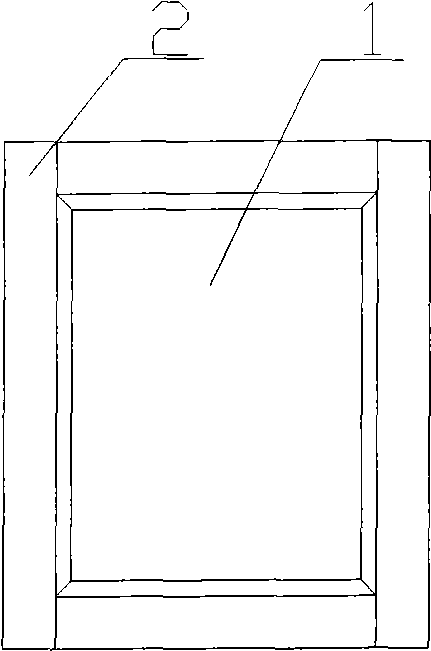

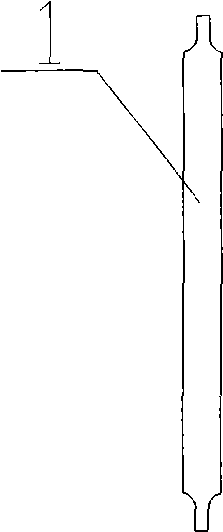

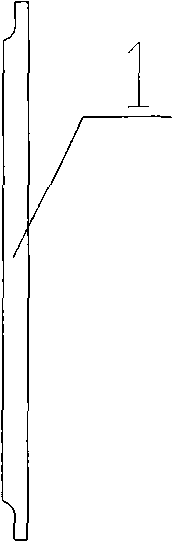

[0016] Embodiment 1: with reference to attached Figure 1~4 . The log frame-shaped board is composed of a rectangular frame 2 and a solid wood board 1. The solid wood board 1 is embedded in the groove inside the rectangular frame 2. It matches the convex-concave-convex structure around the inner side of rectangle 2. A groove is formed on the upper and lower horizontal frames of the rectangular frame 2 and the width of the groove is equal to the thickness of the rectangular frame.

Embodiment 2

[0017] Embodiment 2: with reference to attached Figure 5 . On the basis of Embodiment 1, two or more nuts 5 are built into the end face of the rectangular frame 2 in a log frame-shaped board, and there are grooves in the rectangular frame 2 of the other log frame-shaped board, and the bosses are connected. The boss in the part 3 is inserted in the groove of the rectangular frame 2 of another log frame-shaped board, and the boss body adopts screw 4 to connect with the nut in the log frame-shaped board and connects two log frame-shaped boards as a whole.

Embodiment 3

[0018] Embodiment 3: with reference to attached Image 6 . On the basis of embodiment 1, there are 2 or more grooves on the upper and lower horizontal frames of the rectangular frame 2 in the log frame-shaped board, and the concave sleeve 6 is embedded in the groove, and the groove bottom of the concave sleeve Have screw through hole and screw through hole is provided with screw 7, and this screw 7 is connected with the expansion plug in the end face of another rectangular frame 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com