Liquid surface sealing of clip-shaped slot structure

A liquid surface and sealing device technology, which is applied in the connection of packing seal with fluid pressure, pipes/pipe joints/fittings, passing components, etc., can solve the problem of liquid surface sealing of the return palace groove structure that has not yet been seen, and achieve resistance Small size, good sealing, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

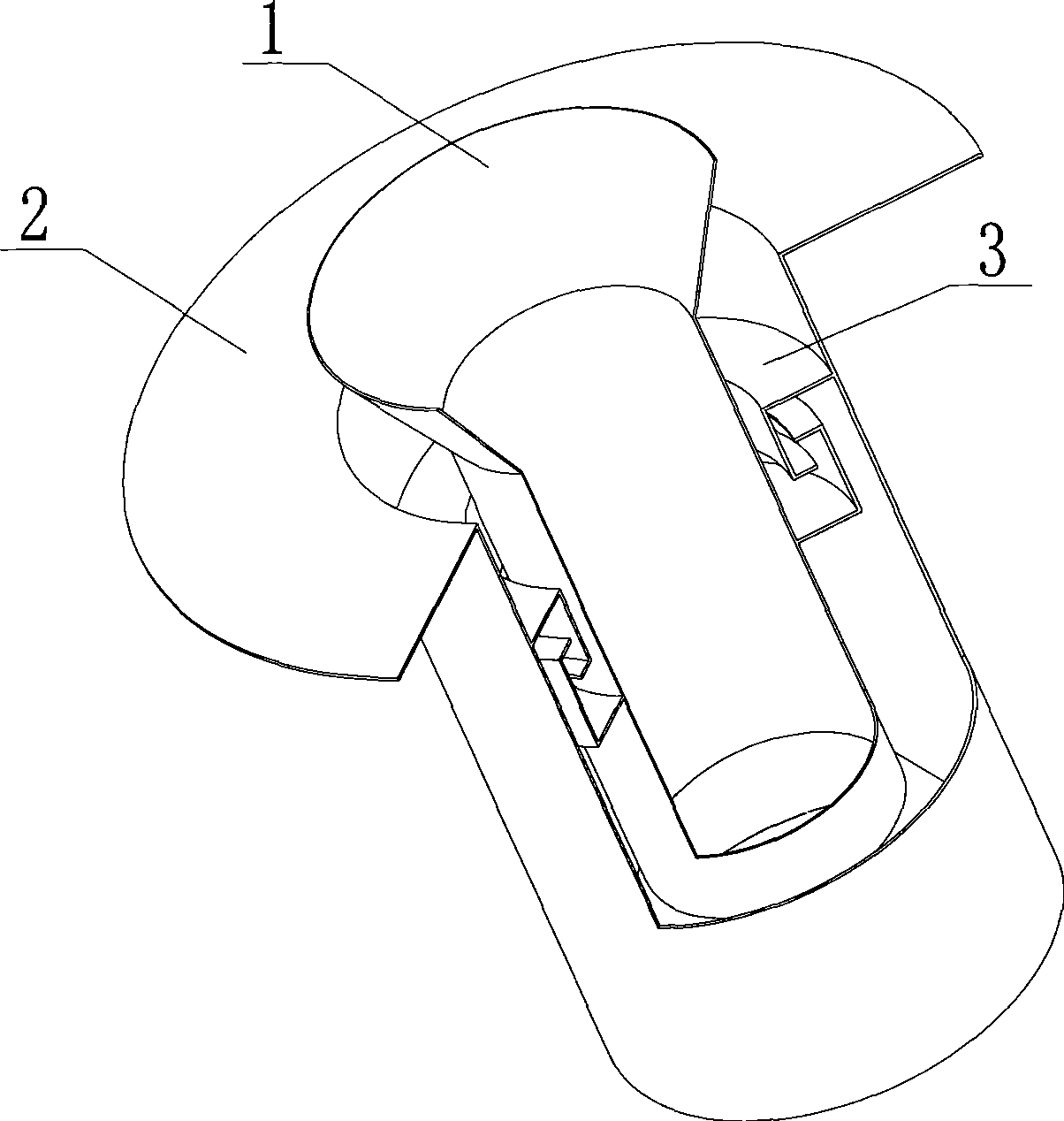

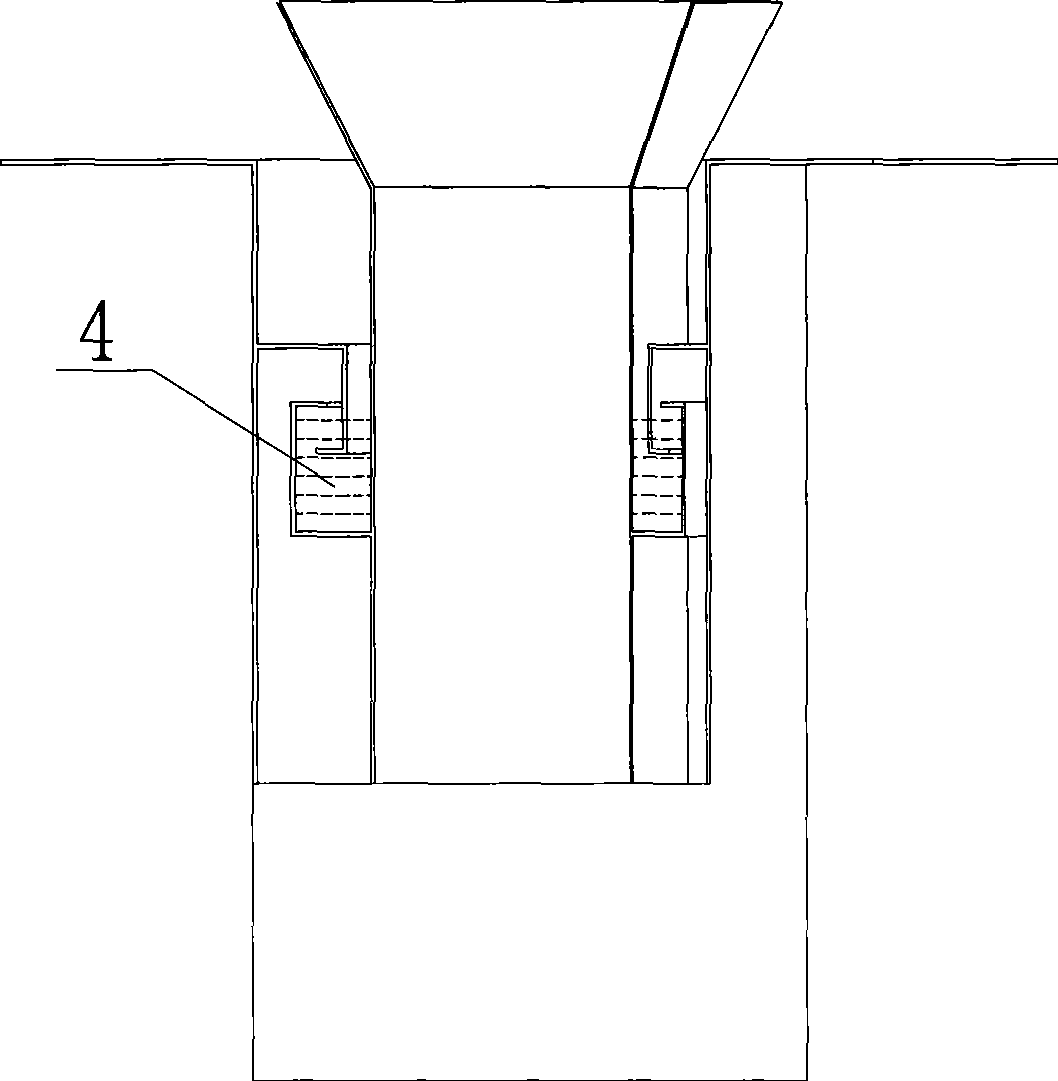

[0012] As shown in the figure, the liquid surface sealing device of the return palace groove structure, the working principle of the liquid surface sealing structure device is as follows: the 1-fixed element is inverted between the nozzle of the funnel and the nozzle of the 2-rotating element, and 3- The structure of the return palace groove is in the form of gap connection, and a certain amount of 4-working fluid is added to the structure of the 3-return palace groove, and the height of the liquid level must meet the design requirements. When the air flows through the 1-fixed element inverted funnel nozzle into the 2-rotating element tube, due to the sudden expansion of the cross-sectional area of the nozzle, the flow rate increases, and its pressure drops to form a violent vortex, the speed is almost completely lost, and the pressure gradually decreases, starting from 4-working The space between the liquid level and the cavity of the 3-return palace groove structure is alwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com