Carrying apparatus

A handling device and technology for handling objects, which are used in transportation and packaging, devices for coating liquid on surfaces, conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings, but the present invention is not limited to the forms shown in the drawings and includes all embodiments that satisfy the requirements described in the claims. In addition, in this specification, the conveyance direction (see arrow F in the figure) is regarded as the front, and the right and left are divided according to this. And, look at the main view from the left.

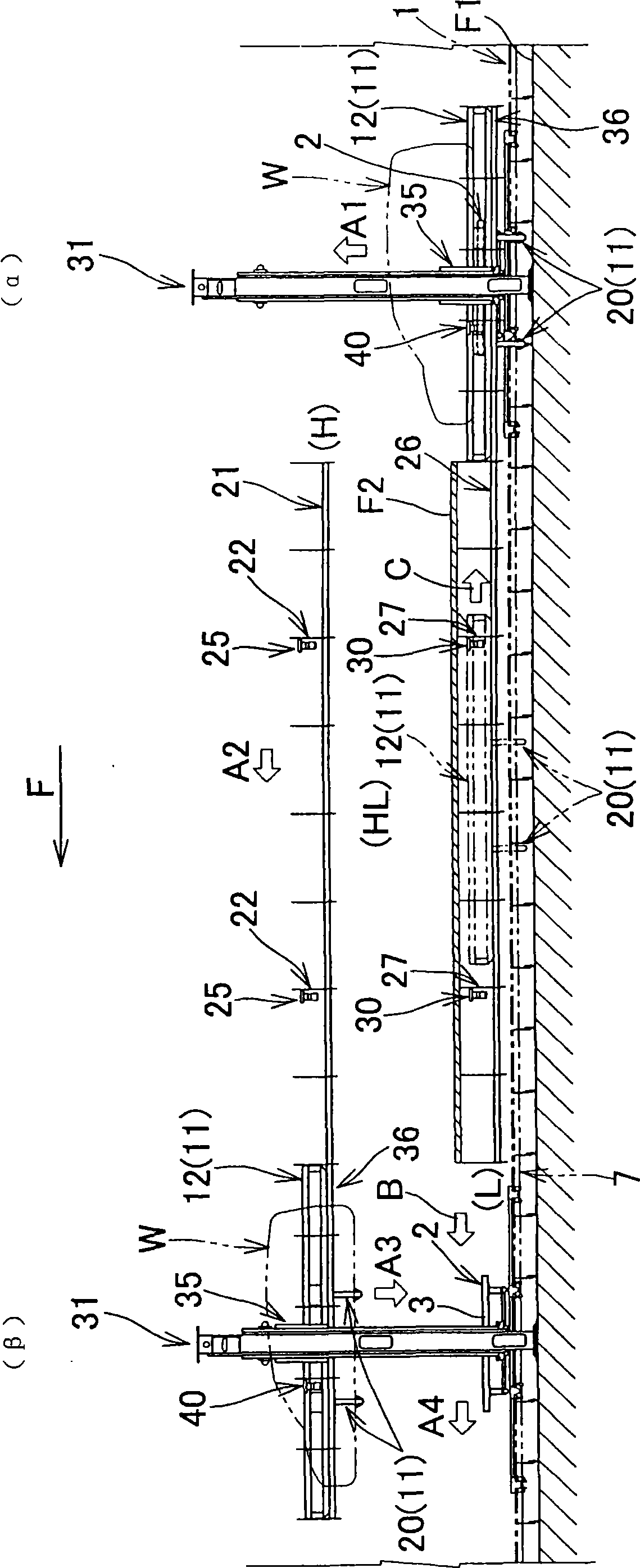

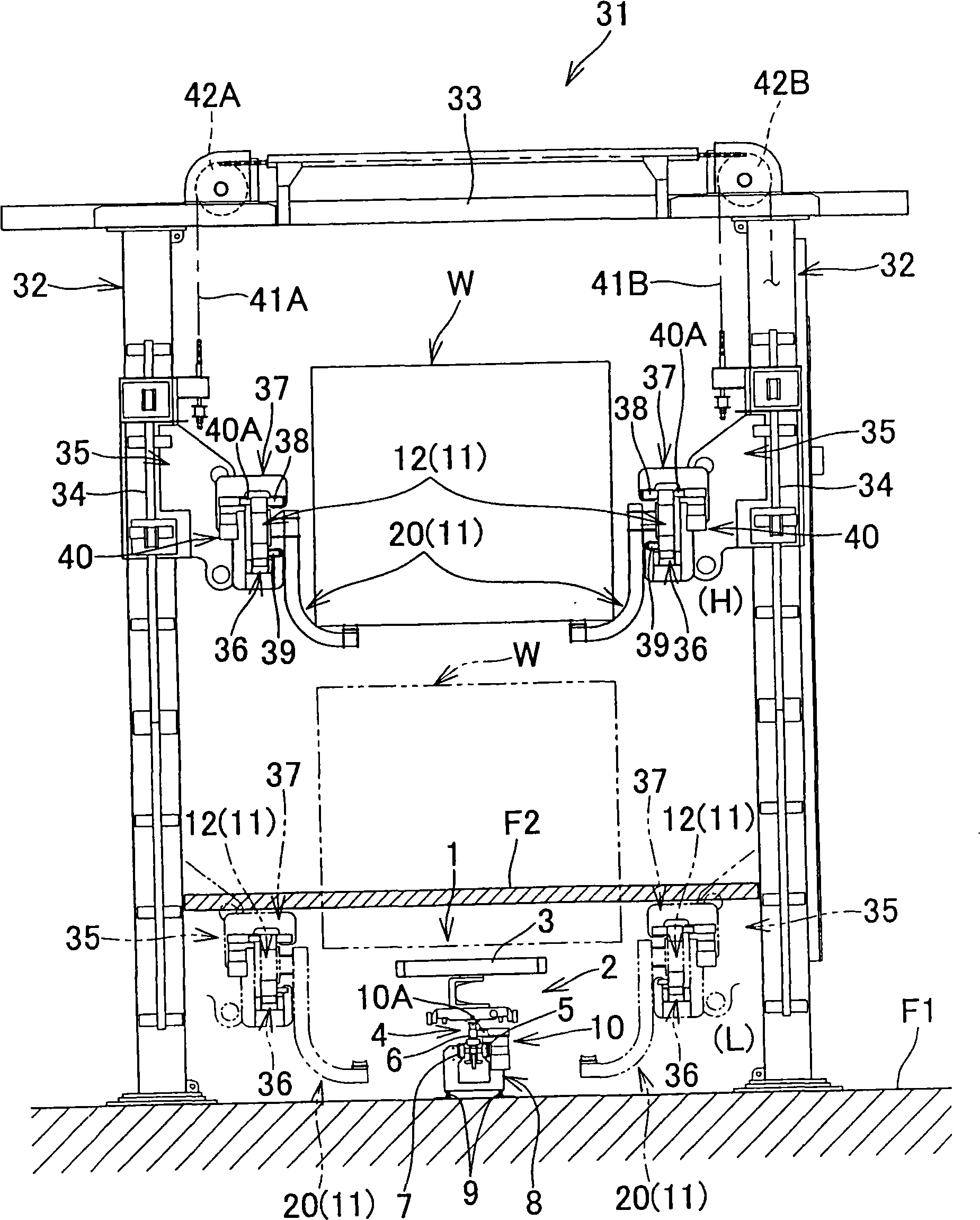

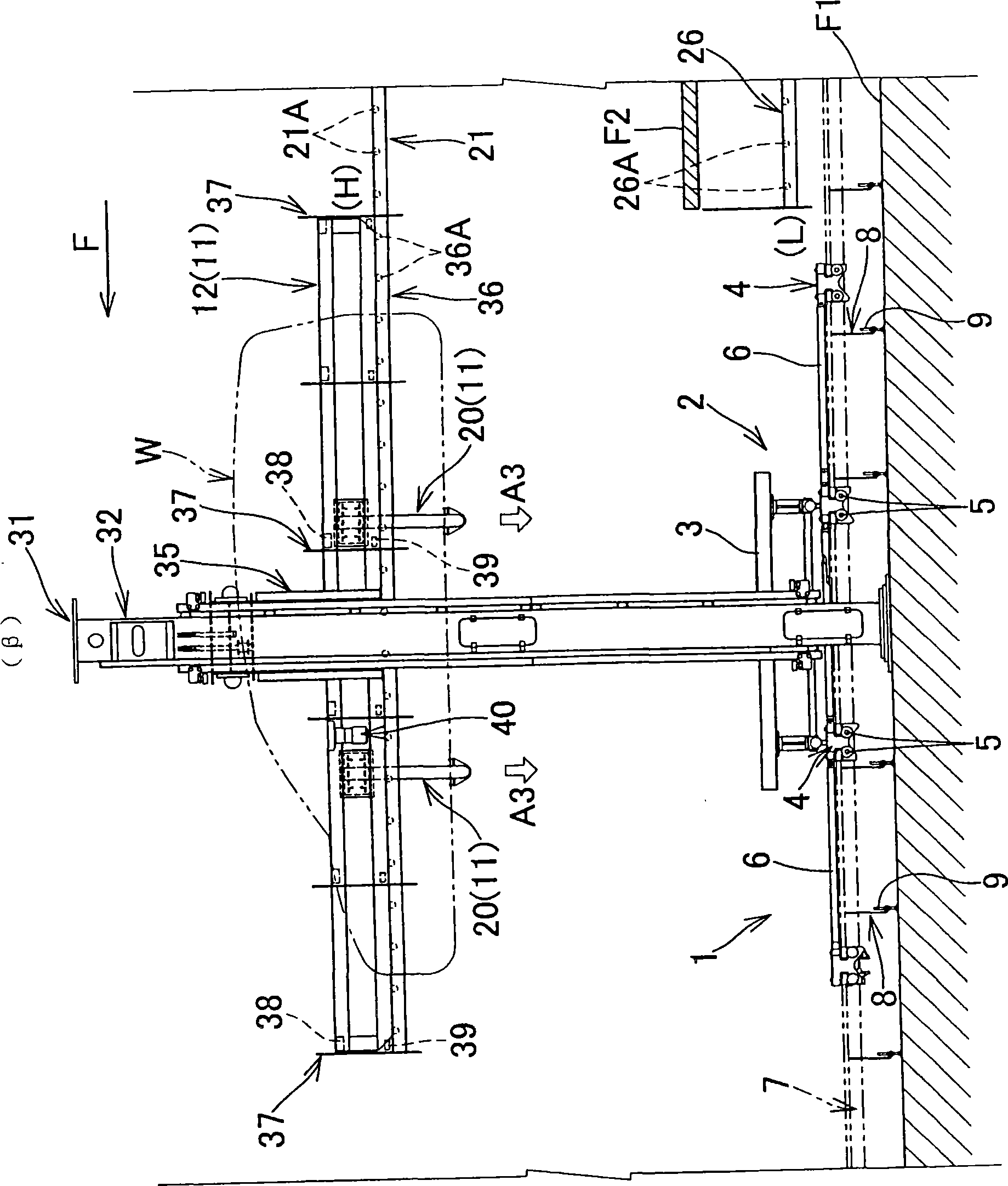

[0029] Figure 1 to Figure 7 It is a schematic diagram showing the structure of the conveying device according to the embodiment of the present invention. figure 1 To represent the front view around the ascending line, figure 2 To see the figure of the lifter from the rear, image 3 is an enlarged front view around the downstream side riser, Figure 4 is a perspective view of the carrier, Figure 5 It is a front view showing the transfer of objects on the downstream side of the ascending wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com