Mixed power electromechanical coupling power transmission device

A technology of power transmission and electromechanical coupling, which is applied in the arrangement of multiple different prime movers of power plants, pneumatic power plants, and general power plants, etc., can solve the requirement of heavy hybridization and integration of hybrid power systems. , low research level, etc., to achieve the effect of convenient control, reduced components, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

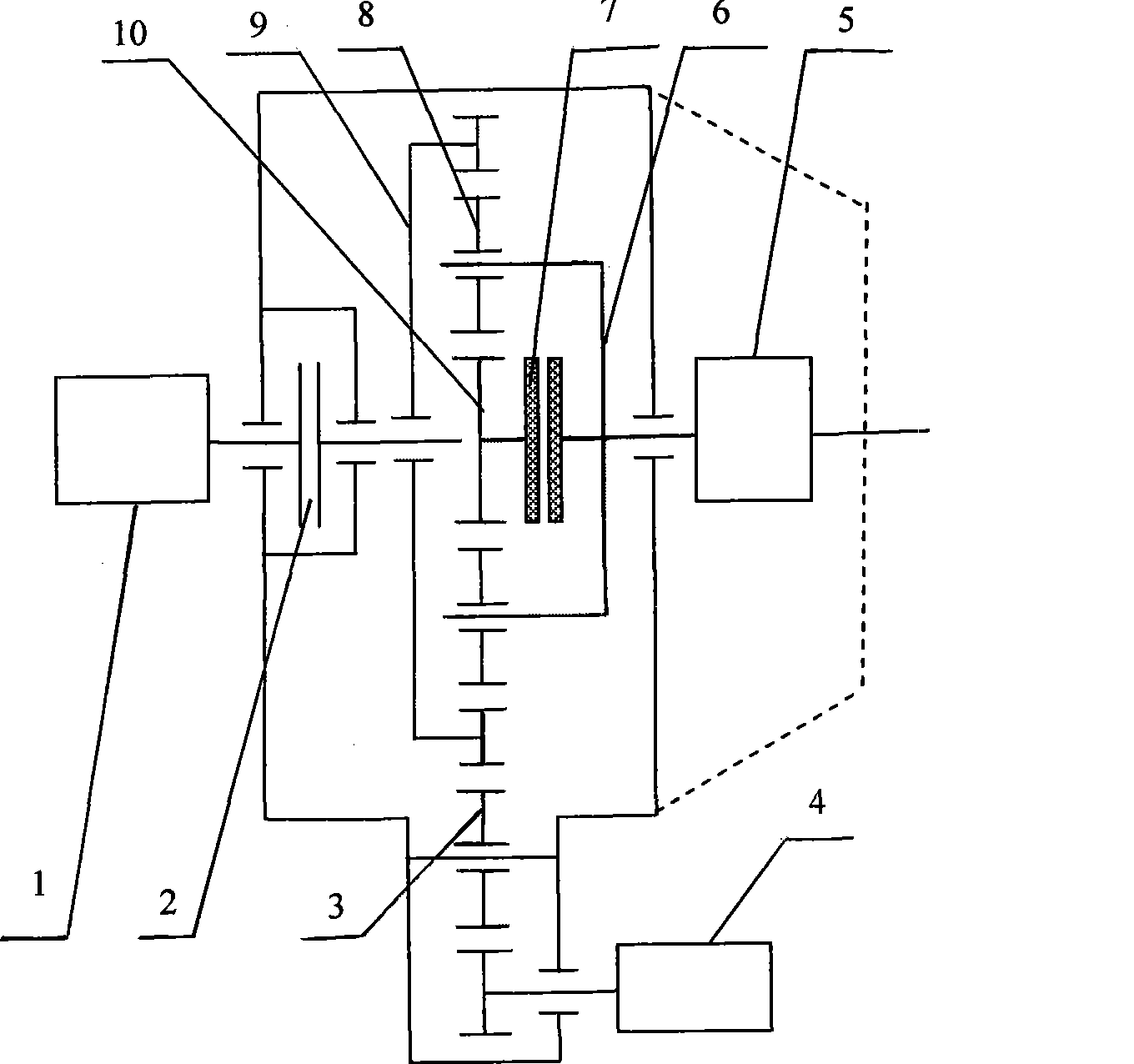

[0012] This embodiment is an electromechanical coupling power transmission device for hybrid power, the structure is as follows figure 1 As shown, it includes a single-row planetary helical gear mechanism, a brake 7 and a clutch 2. Both the clutch 2 and the brake 7 are wet. The single-row planetary helical gear mechanism includes a planetary gear carrier 6, and a row of The planetary gear 8 whose gear tooth profile is helical, the sun gear 10 and the ring gear 9 meshed with the planetary gear 8, at least two planetary gears 8 are evenly distributed in the single-row planetary cylindrical helical gear mechanism. A brake 7 is connected between the sun gear 10 and the planetary gear carrier 6, and the brake 7 is coaxially arranged with the sun gear 10. The brake 7 can lock and separate the movement of the sun gear 10 and the planetary gear carrier 6, so that the single-row planetary cylindrical helical gear mechanism The lock is integrated, the transmission coefficient becomes 1,...

Embodiment 2

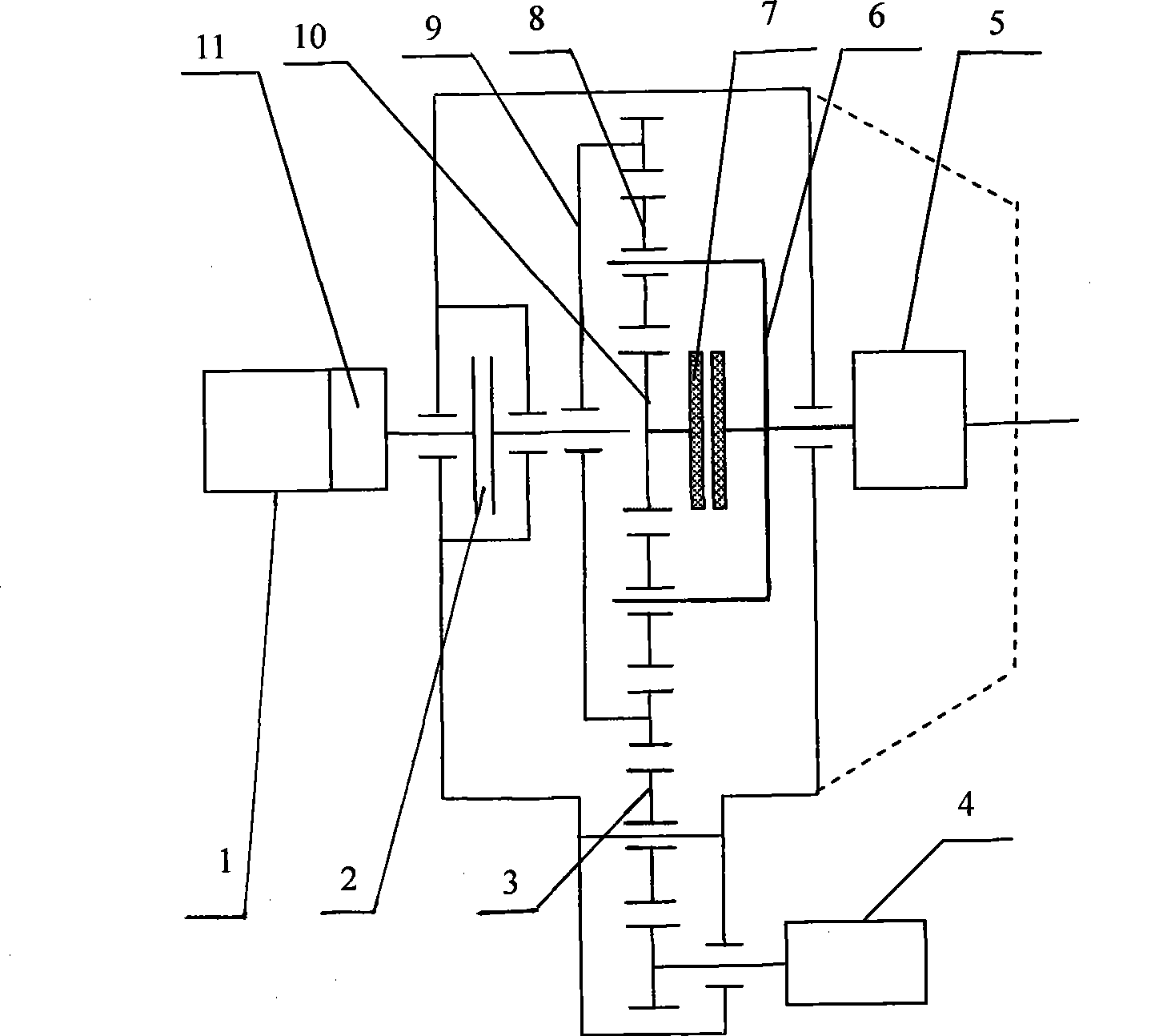

[0018] Such as figure 2 As shown, the difference between the electromechanical coupling power transmission device for hybrid power of this embodiment and the first embodiment is that an ISG motor 11 is connected between the output end of the internal combustion engine 1 and the clutch 2, and the torque of the internal combustion engine 1 and the torque of the ISG motor 11 are in the coupling device. Superimposed before, by adjusting the ISG motor 11 and the motor 4 to make the internal combustion engine 1 run in its optimum working area. During acceleration, the ISG motor 11 provides power assist to make up for the low torque of the internal combustion engine 1 at low speed, and implements braking energy recovery during deceleration and braking, so that the ISG motor 11 generates electricity and stores it in the power battery. When parking, the internal combustion engine 1 is turned off, eliminating the idling state of high fuel consumption and poor emission; when starting, t...

Embodiment 3

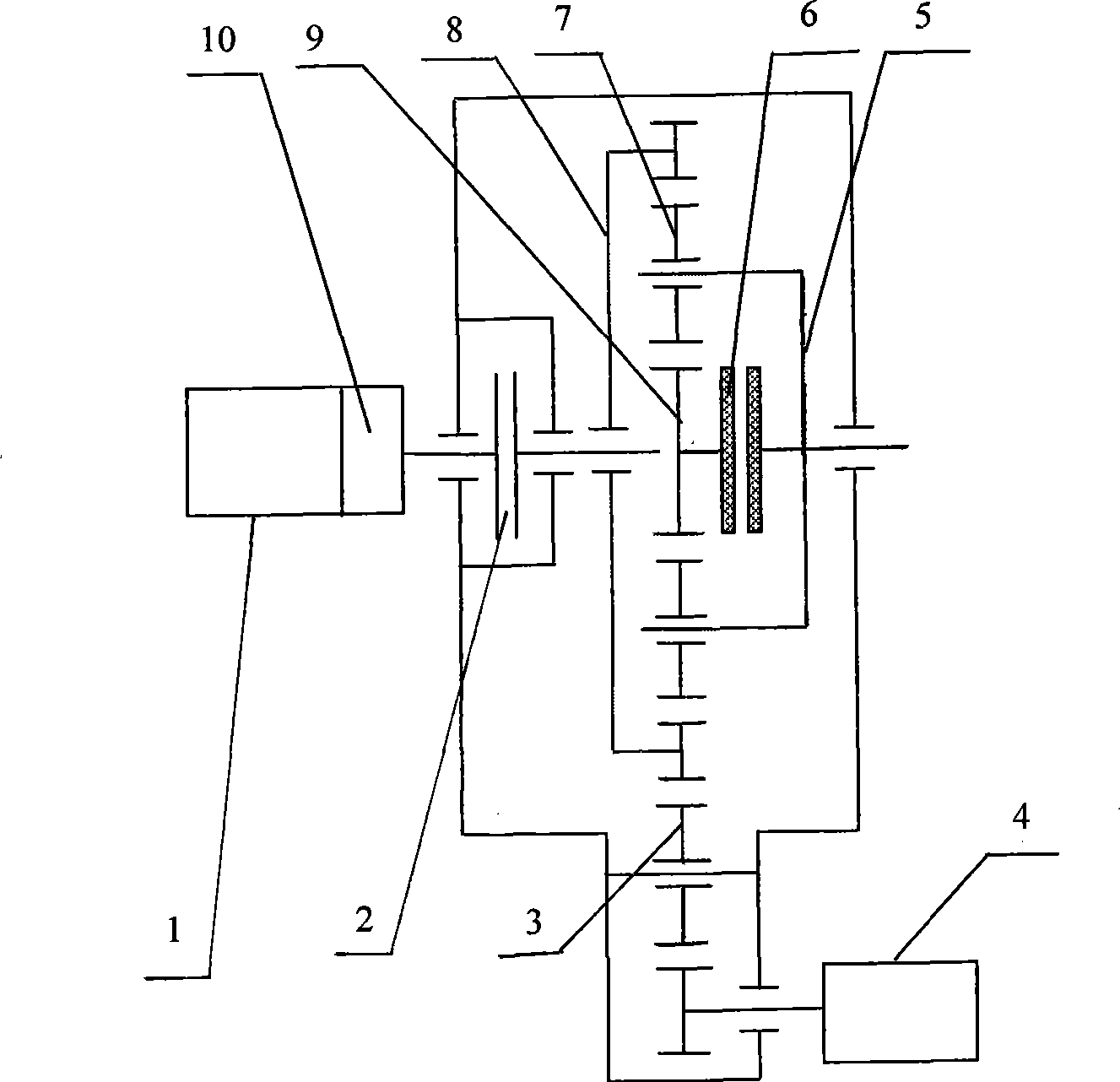

[0020] Such as image 3 As shown, the difference between the electromechanical coupling power transmission device for hybrid power in this embodiment and the first embodiment is that the ISG motor 10 is connected between the output end of the internal combustion engine 1 and the clutch 2, and there is no speed change connection between the planetary carrier 6 and the final reducer. mechanism, the power output by the planetary carrier 6 is directly transmitted to the drive axle through the reducer. In addition, the reverse gear of the automobile using this embodiment is realized through the reverse rotation of the motor, and the adjustment of the vehicle speed is realized through the wide speed regulation range of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com