Handheld rapid fixture

A handheld and fast technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problems of poor positioning effect, difficult pressing and use of clamps, insufficient clamping or expansion force, etc., to achieve the effect of good tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

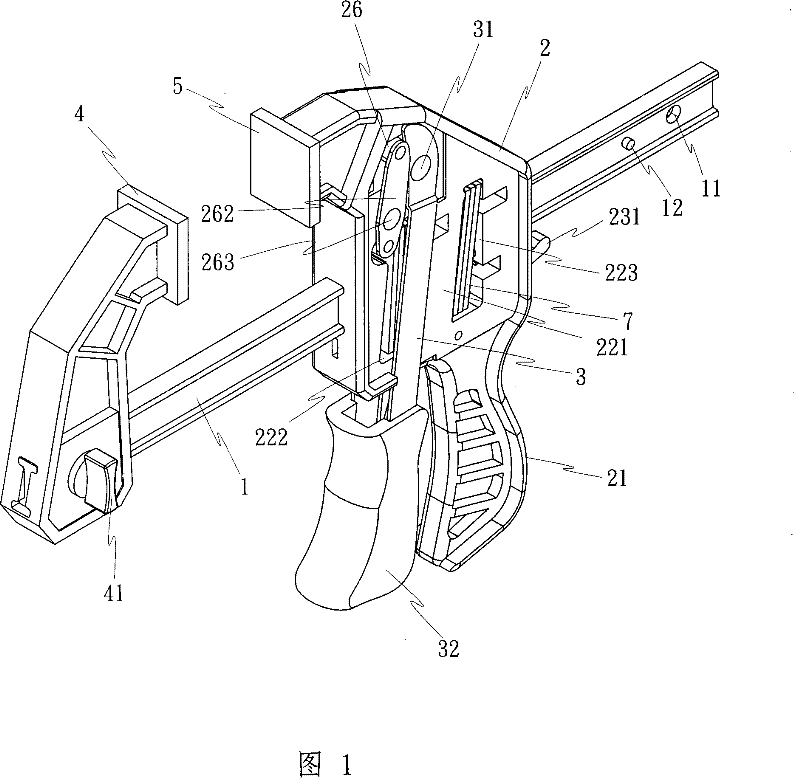

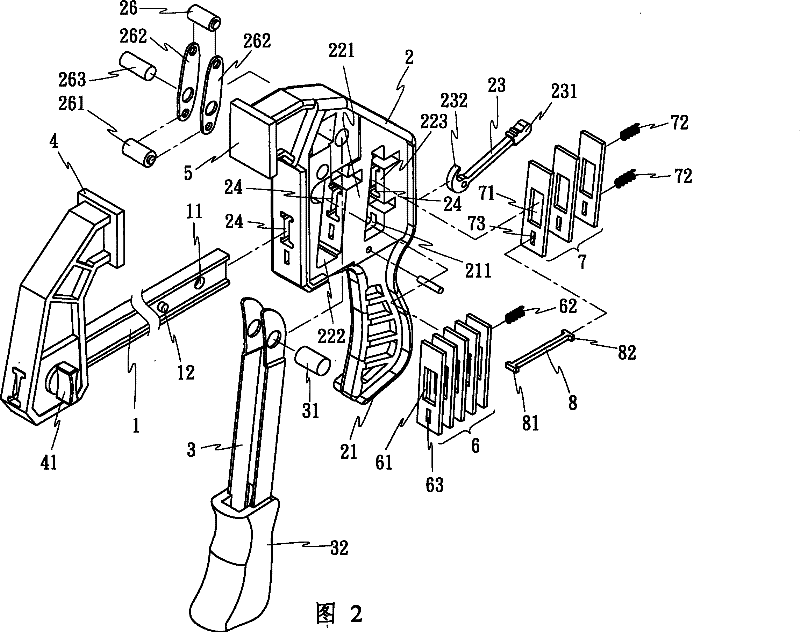

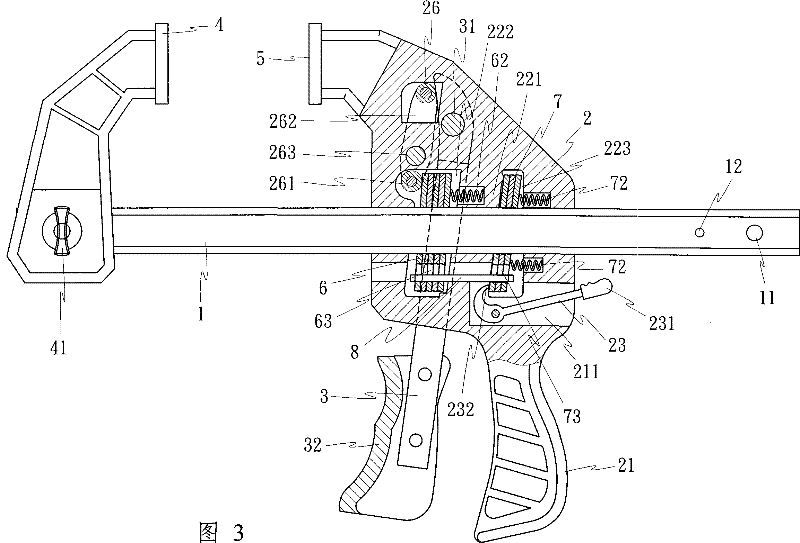

[0018] Such as Figure 1 to Figure 3 As shown, the hand-held quick clamp in the present invention includes: a moving rod 1, a fixed handle 2, a driving handle 3, a first clamping block 4 and a second clamping block 5 and other components, and the moving rod 1 runs through the fixed handle 2, a A set of action pieces 6 and a set of stop pieces 7, wherein:

[0019] Moving rod 1 is a strip rod body, which can be selected as Figure 1 to Figure 3 The shown I-shaped rod body or any rod body with better strength is provided with locking holes 11 and protruding stoppers 12 at both ends of the rod body, so that one end of the first clamping block 4 can be used to lock one end of the rod body. Combine;

[0020] The fixed handle 2, the lower end is the grip part 21, the upper end utilizes the partition rib 221 to form a front accommodating chamber 222 and a rear accommodating chamber 223, and a second clamping block 5 is arranged above the fixed handle 2, and the grip part 21 is opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com