Fixing device for welding scan box of electron accelerator

An electron accelerator and fixing device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of high production cost, many labor, poor welding quality, etc., to save mechanical correction steps, save labor and man-hours , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

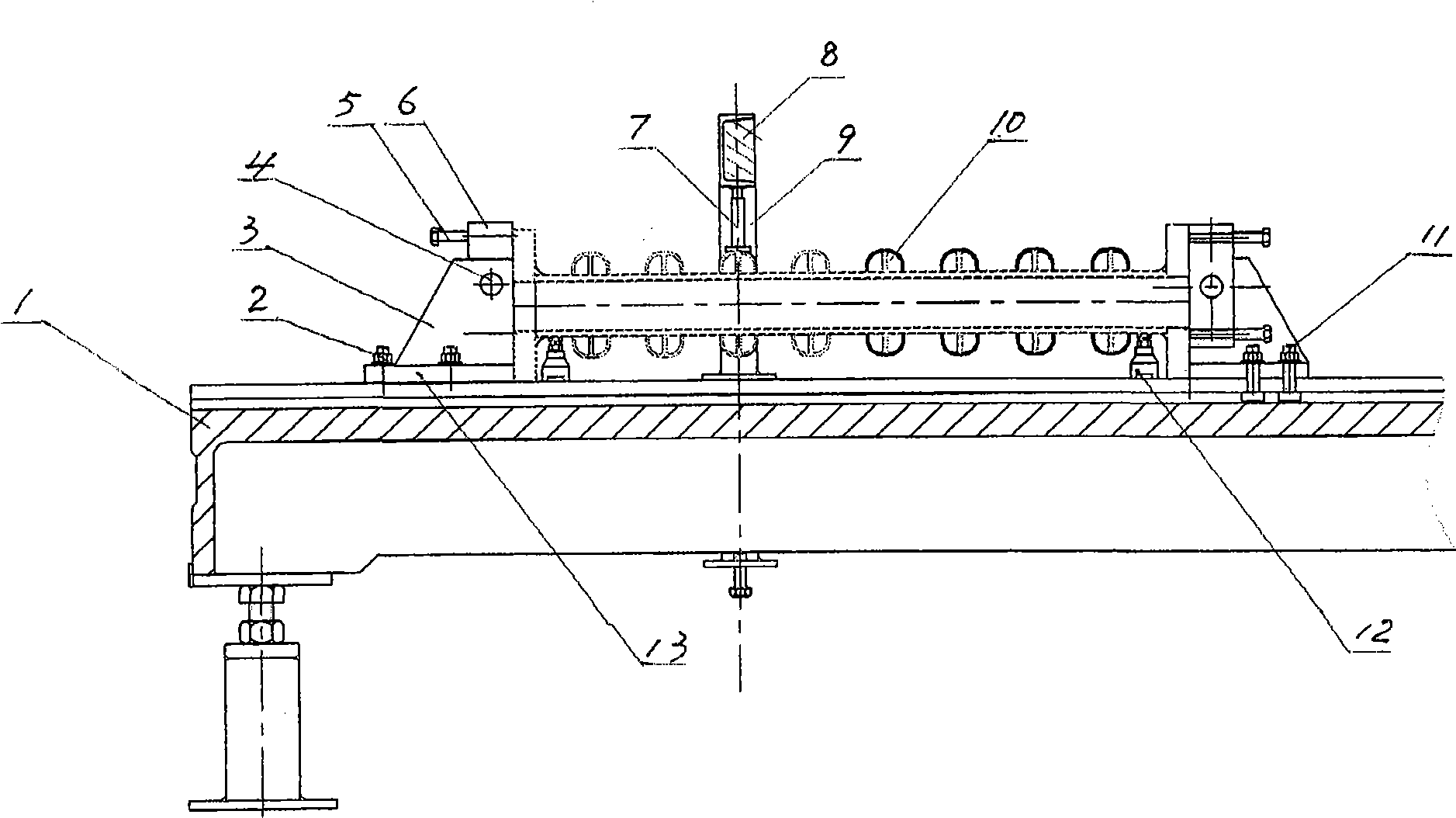

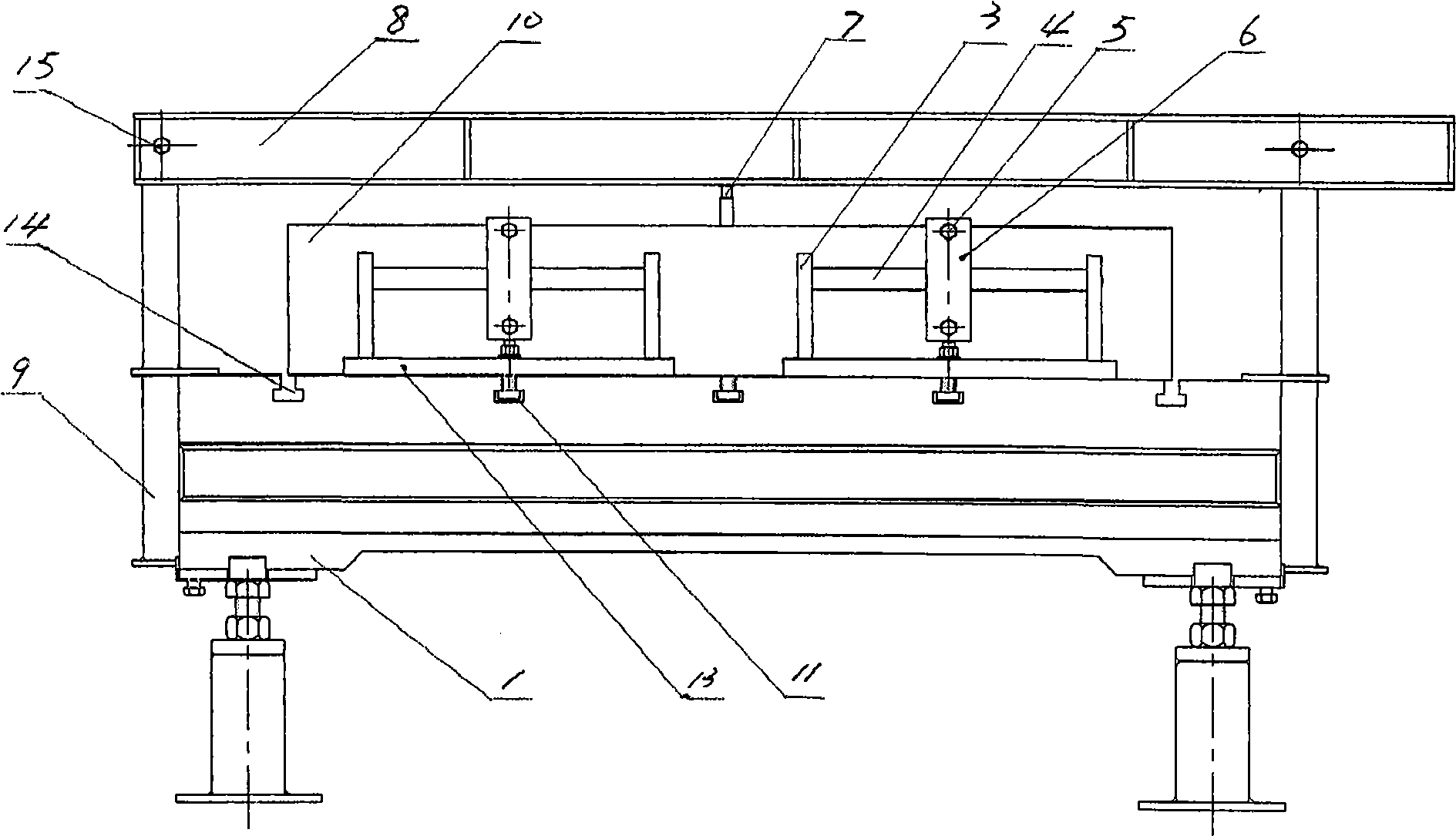

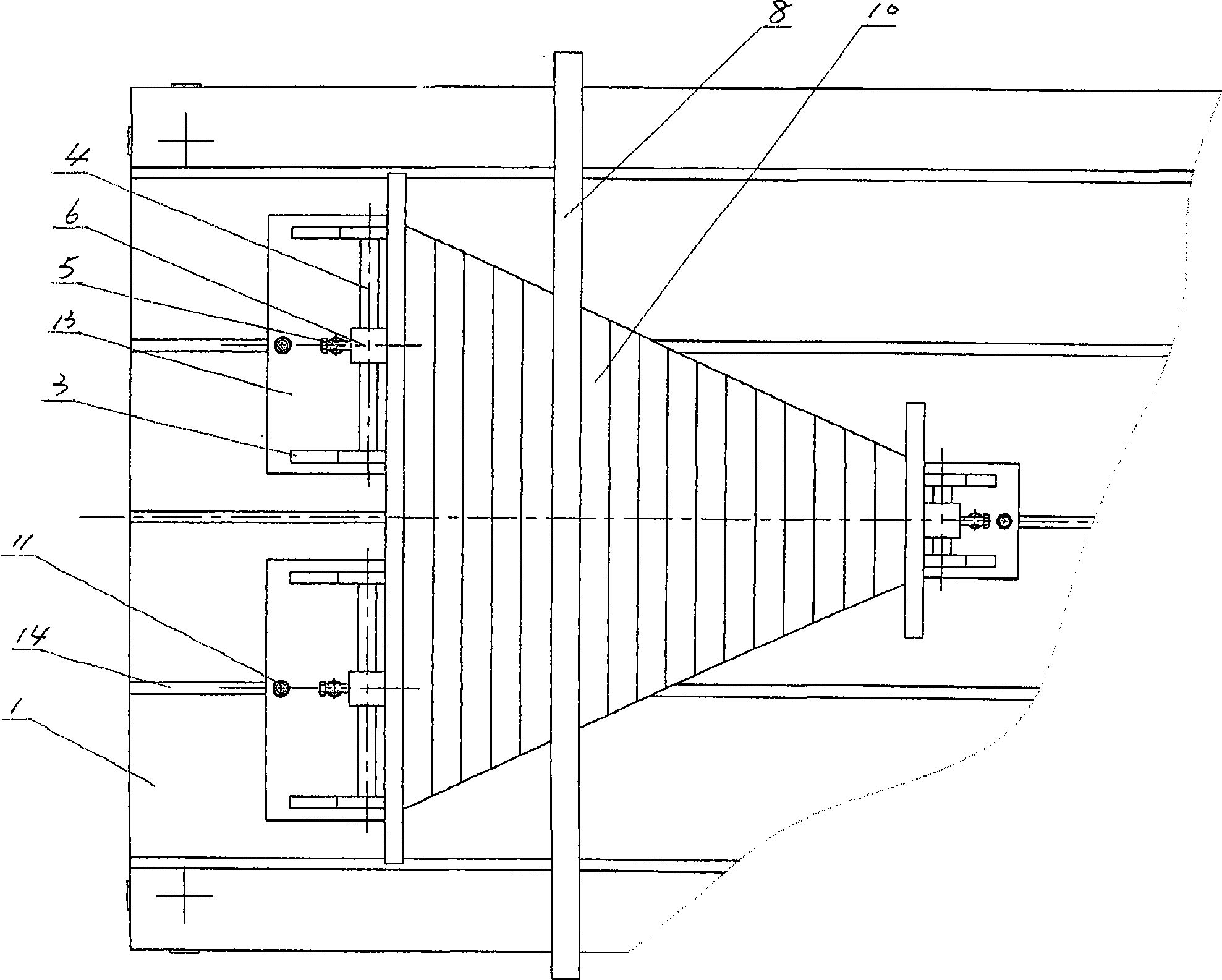

[0013] Such as figure 1 , figure 2 and image 3 As shown, the fixing device for electron accelerator scanning box welding of the present invention includes a working platform 1 , which is rectangular, and positioning mechanisms for fixing the scanning box 10 are provided at both ends of the working platform. A number of longitudinal grooves 14 are processed on the table of the working platform 1, and these longitudinal grooves 14 are arranged at equal intervals, and their cross-sections are inverted T-shaped. Described positioning mechanism comprises horizontal plate 13, and this horizontal plate is rectangular, is provided with two vertical plates 3 on it. The board faces of the two vertical plates 3 are parallel and perpendicular to the long sides of the horizontal plates 13 , and their lower ends are welded together with the two short sides of the horizontal plates 13 respectively. A horizontal bar 4 is arranged between the two vertical plates 3, and a vertical iron blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com