Stretch-bending forming die and forming method

A stretch-bending forming and mold technology, applied in the field of stretch-bending forming molds and forming, can solve the problems of difficulty in ensuring the forming accuracy of workpieces, a large number of molds, and high production costs, so as to reduce the design and manufacturing cycle, reduce production costs, and improve manufacturing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

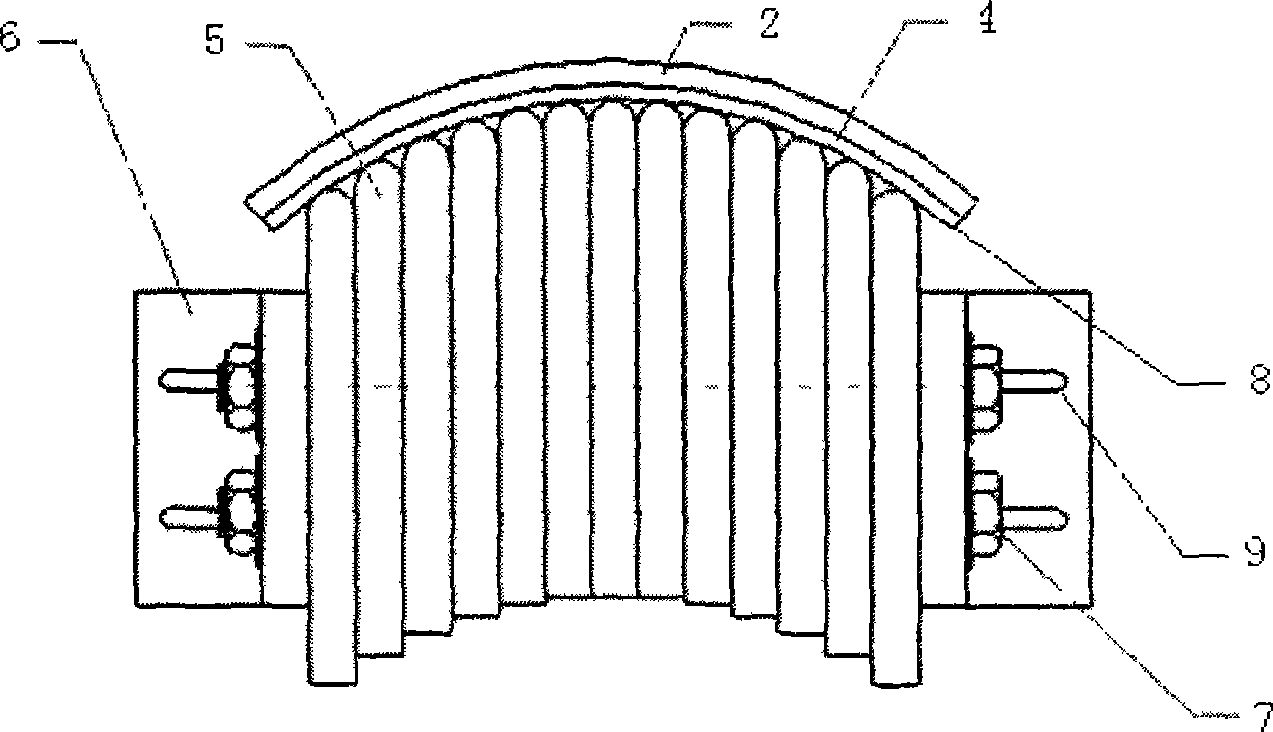

[0032] This embodiment is a stretch-bending die for forming a rectangular profile part with a section of 15*20mm, a radius of 350mm, and a length of 510mm. It is characterized in that multiple discrete basic bodies are integrated into a certain profile. mold, and the mold can be arbitrarily combined according to the requirements of the formed profile. The mold includes a basic body 5 , a cushion layer 4 , two clamping blocks 6 , and bolts 7 .

[0033] In this embodiment, the basic body is the basic unit of the mold, and 13 basic bodies are integrated into a mold. The external dimensions of the basic body are determined according to the load of the tensile bending load and the requirements for the rigidity of the mold. For the convenience of processing and use, the working arc surface of the basic body in this embodiment is an arc surface, and the diameter of the arc is equal to the thickness of the basic body. The basic body 5 is a cuboid with a rectangular cross section, a ...

Embodiment 2

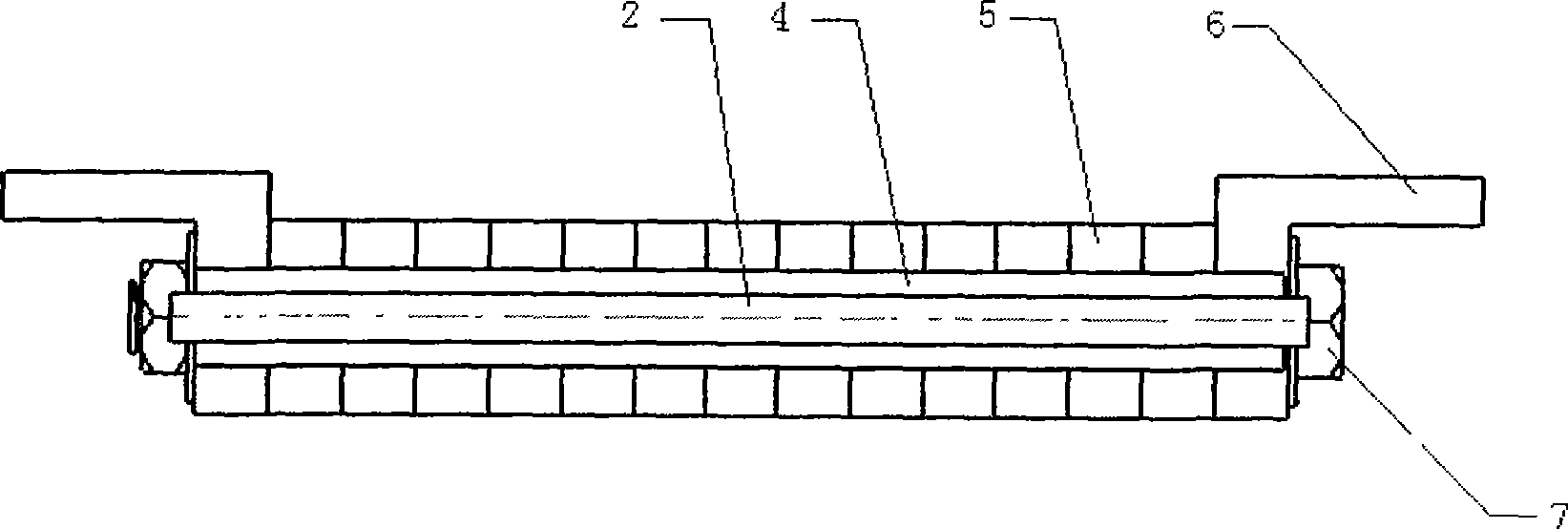

[0046] This embodiment is a stretch-bending die for forming a rectangular profile part with a section of 150*200mm, a radius of 3000mm, and a length of 3140mm. It is characterized in that multiple discrete basic bodies are integrated into a certain profile. mold, and the mold can be arbitrarily combined according to the requirements of the formed profile. The mold includes a basic body 5 , a cushion layer 4 , two clamping blocks 6 , and bolts 7 .

[0047] In this embodiment, the basic body is the basic unit of the mold, and 20 basic bodies are integrated into a mold. The external dimensions of the basic body are determined according to the load of the tensile bending load and the requirements for the rigidity of the mold. The working arc surface of the basic body is an elliptical arc surface, and the length ratio of the minor axis to the major axis should be between 0.2-1. The diameter of the major axis of the ellipse in this embodiment is equal to the thickness of the basic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com