La, Mn modified Pd/gamma-Al2O3 catalyst and preparation method thereof

A catalyst and modification technology, applied in the field of low calorific value gas catalytic combustion, can solve the problems of difficult large-scale industrial application, complicated preparation methods, etc., and achieve the effects of long catalyst life, simple preparation process and low light-off temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Preparation of 0.1Pd / La / Al 2 o 3

[0018] Determine 10g γ-Al 2 o 3 The water absorption capacity is 8.4 ml, weigh 6 g of lanthanum nitrate hexahydrate and dissolve it in 8.4 ml of deionized water, and mix it with 10 g of γ-Al 2 o 3 Mix evenly, dry at 120°C overnight after standing for two hours, and bake at 800°C in a muffle furnace for 4 hours. Obtain 12.5g intermediate carrier La / Al 2 o 3 ; with 8.4 mL H 2 PdCl 4 Solution (PdCl 2 0.2g) impregnated La / Al 2 o 3 , and then cleaned until it does not contain Cl ions, dried overnight at 120°C, and finally placed in a muffle furnace and roasted at 1000°C for 4 hours to obtain the desired catalyst Pd / La / Al 2 o 3 , where the mass percent of the composition is: 80% γ-Al 2 o 3 , 0.1% Pd, 19.9% La.

Embodiment 2

[0019] Embodiment 2: Preparation of 0.1Pd / Mn / Al 2 o 3

[0020] Determine 10g γ-Al 2 o 3 The water absorption capacity is 8.4ml, weigh 8.12g manganese nitrate and dissolve it in 8.4ml deionized water, and mix it with 10gγ-Al 2 o 3 Mix evenly, dry at 120°C overnight after standing for two hours, and bake at 800°C in a muffle furnace for 4 hours. Obtain 12.5g intermediate carrier Mn / Al 2 o 3 ; with 8.4 mL H 2 PdCl 4 Solution (PdCl 2 0.2g) impregnated Mn / Al 2 o 3 , washed to no Cl ions, dried at 120°C overnight, and finally placed in a muffle furnace for 4 hours at 1000°C to calcinate to obtain the desired catalyst. 0.1Pd / Mn / Al 2 o 3 The mass percentage of the composition is: 80% γ-Al 2 o 3 , 0.1% Pd, 19.9% Mn.

Embodiment 3

[0021] Example 3: Preparation of 0.1Pd / LaMnAl 11 o 19

[0022] Determine 10g Al 2 o 3 The water absorption capacity is 8.4 ml, weigh 3 g of lanthanum nitrate hexahydrate and 4.06 g of manganese nitrate into 8.4 ml of deionized water, and mix with 10 g of γ-Al 2 o 3 Mix evenly, dry at 120°C overnight after standing for two hours, and bake at 1000°C in a muffle furnace for 4 hours. 12.5 g of intermediate support are obtained. Using 8.4 ml H 2 PdCl 4 Solution (PdCl 2 0.2g) to impregnate the intermediate support, then wash it to contain no Cl ions, dry it overnight at 120°C, and finally place it in a muffle furnace and bake it at 1000°C for 4 hours to obtain the desired catalyst 0.1Pd / LaMnAl 11 o 19 ; The mass percentage of the composition is: 80% γ-Al 2 o 3 And 0.1% noble metal Pd, 9.95% La, 9.95% Mn.

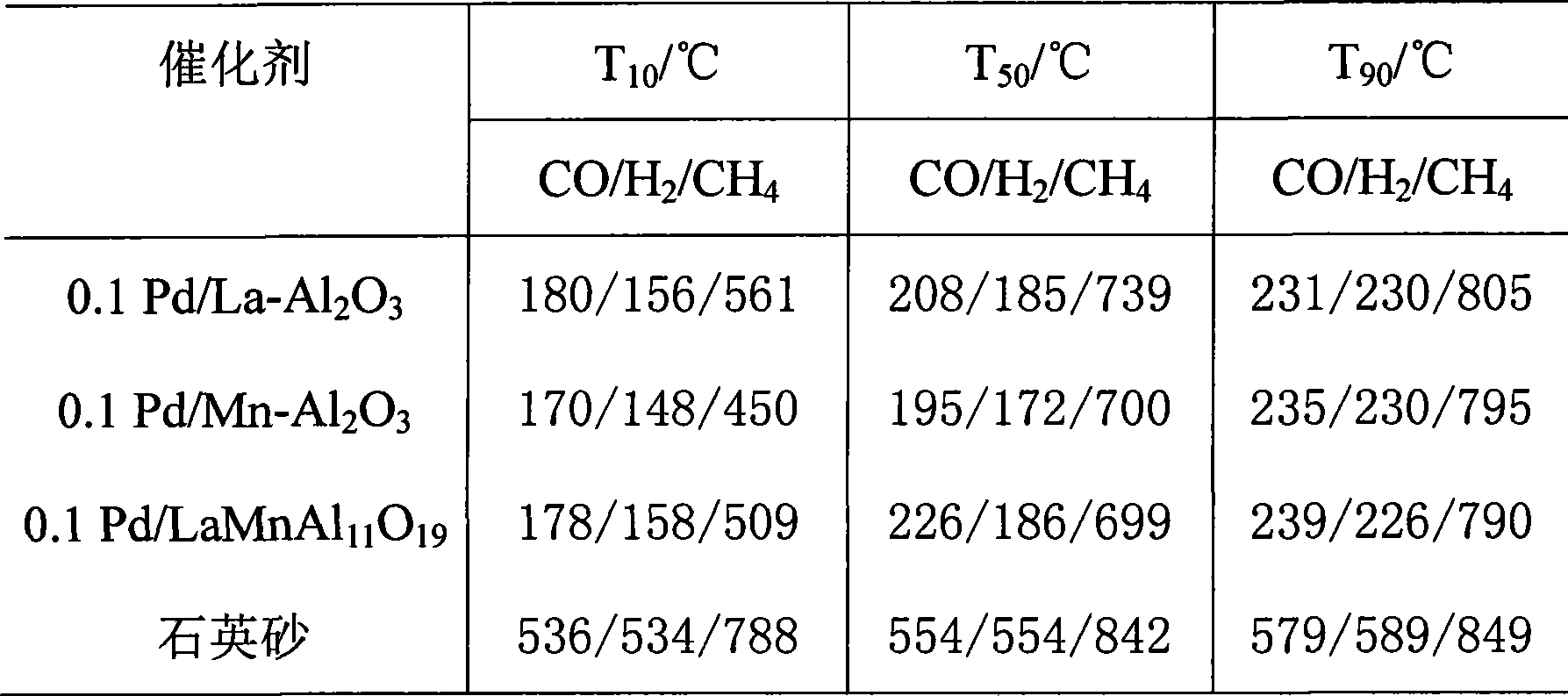

[0023] Prepared 0.1Pd / Mn / Al 2 o 3 , 0.1Pd / La / Al 2 o 3 , 0.1Pd / LaMnAl 11 o 19 The low-temperature ignition activity and high-temperature stability tests of catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com