Pressure sensor

A pressure sensor and pressure technology, applied in the direction of measuring fluid pressure, instruments, measuring fluid pressure through electromagnetic components, etc., can solve the problems of complicated installation and operation, increasing the size of the pressure sensor, increasing the size and weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

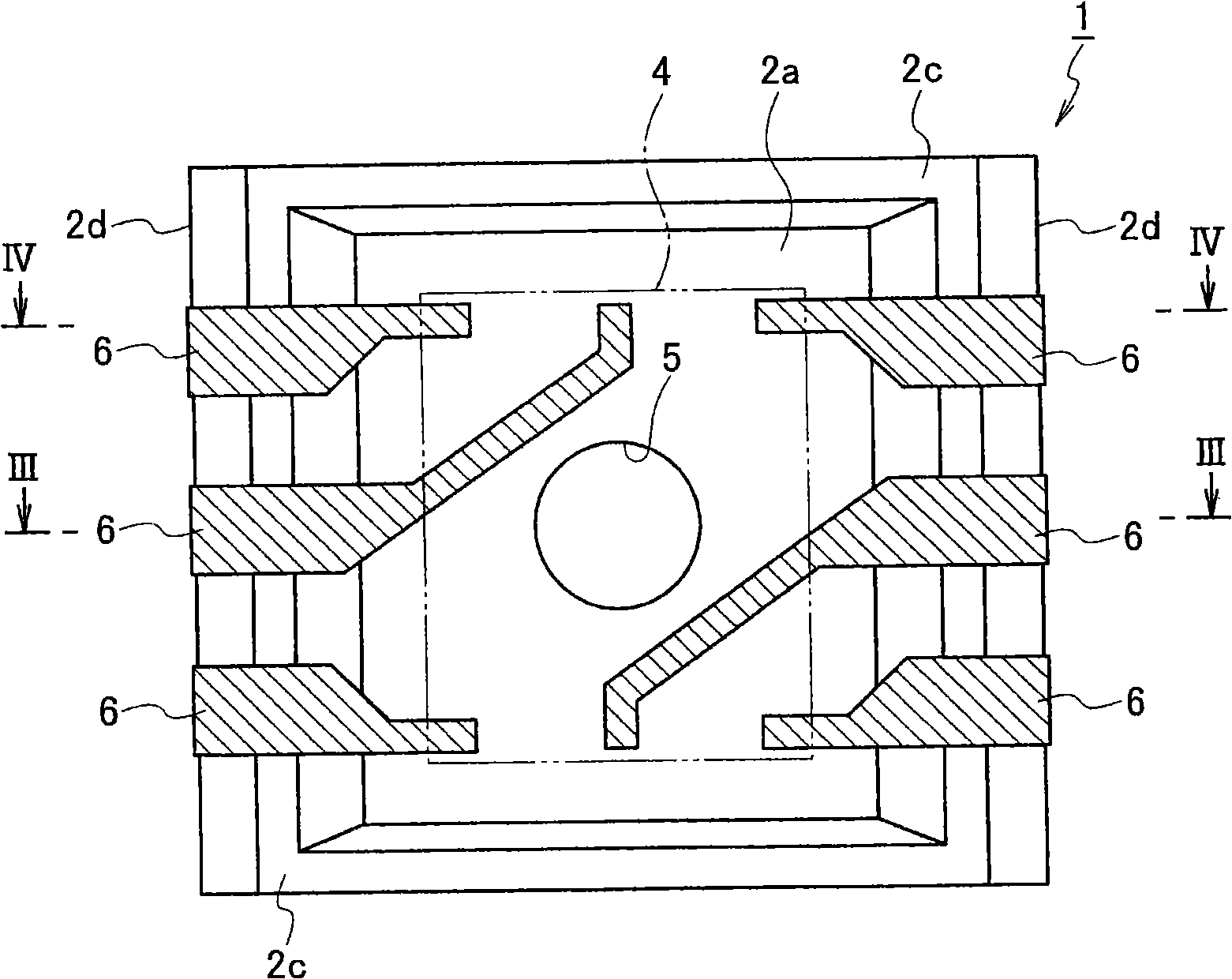

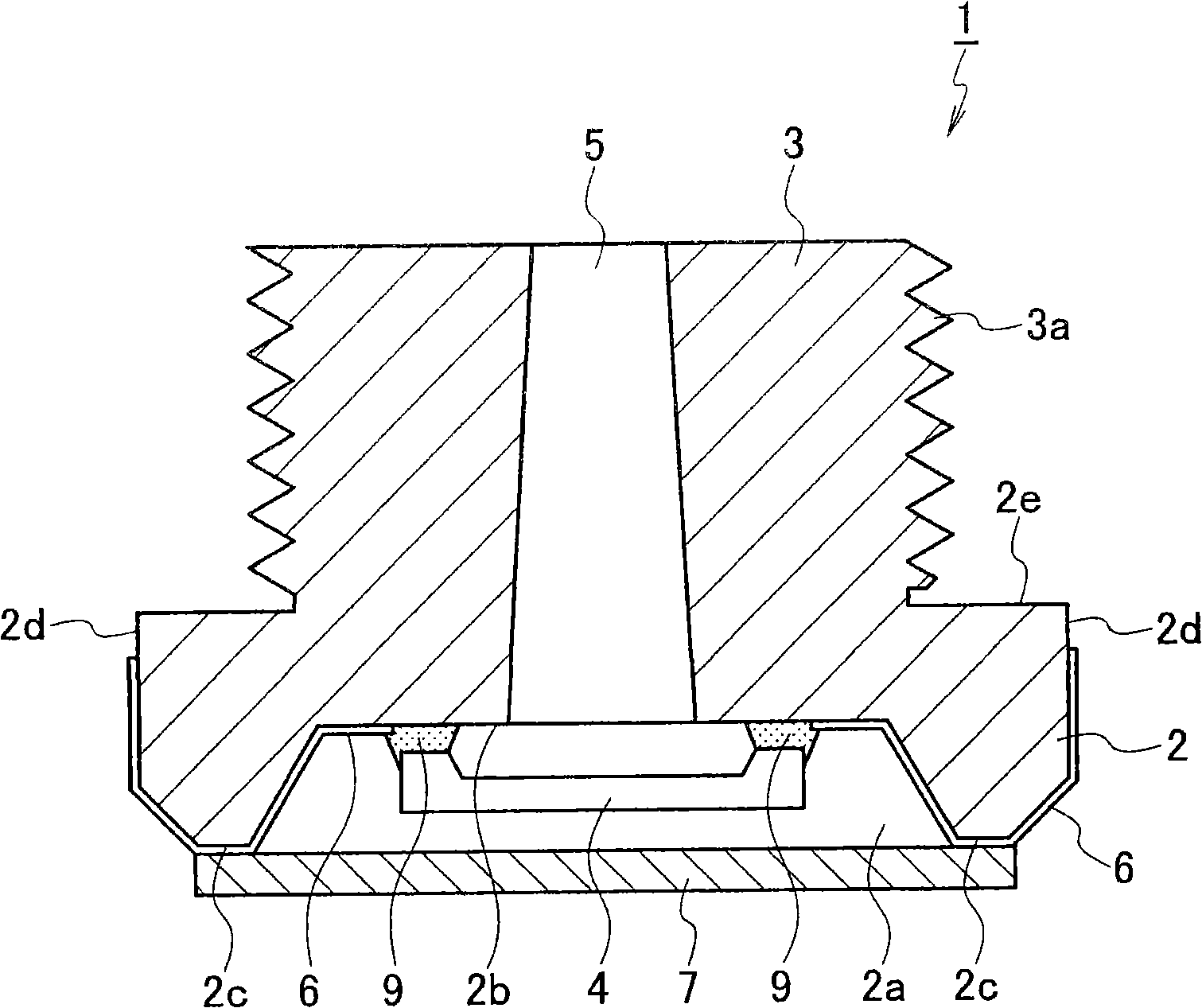

[0042] (first embodiment) figure 1 is a perspective view of a pressure sensor according to a first embodiment of the present invention, figure 2 is a plan view of the pressure sensor viewed from its rear side (the side opposite to the detection side of the pressure detection element), image 3 is along figure 2 A cross-sectional view of line III-III in, Figure 4 is along figure 2 A sectional view of line IV-IV in, Figure 5 is a plan view of the pressure sensor when viewed from its rear side and showing the sealing area where the sealant seals the pressure sensing element, Image 6 It is a side view showing the state where the pressure sensor is mounted.

[0043] A pressure sensor 1 according to an embodiment of the present invention includes a substantially cylindrical protrusion 3 provided on a flat surface (sealing surface) 2e of a base 2 having a substantially cuboid appearance. In this embodiment, the base portion 2 and the protrusion portion 3 correspond to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com