Solid multi-layer type single-plate dryer

A three-dimensional multi-layer, dryer technology, applied in dryers, drying, local stirring dryers, etc., can solve the problems of large steel consumption, large one-time investment, and high operating costs, and reduce labor costs. , less investment, and the effect of improving drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

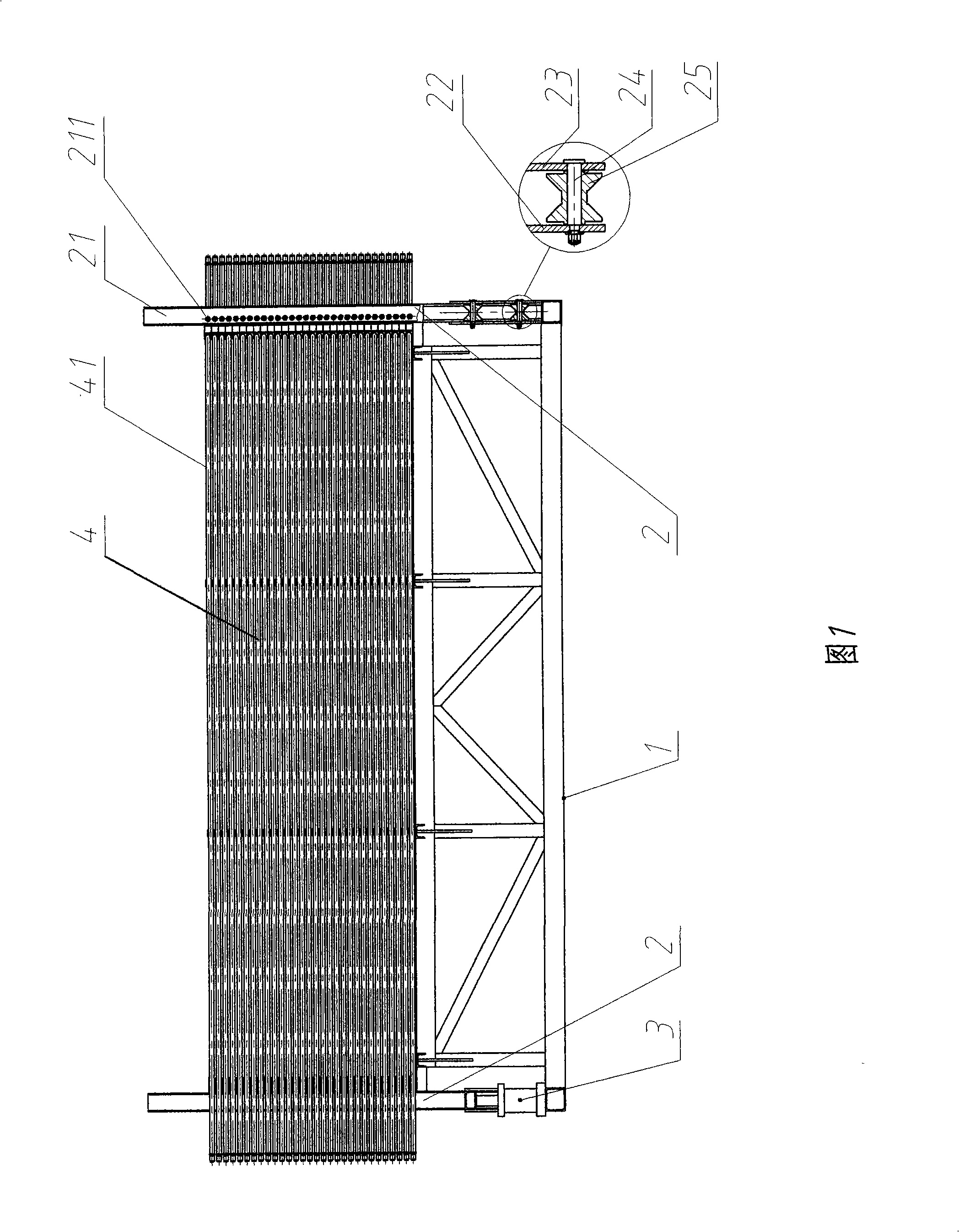

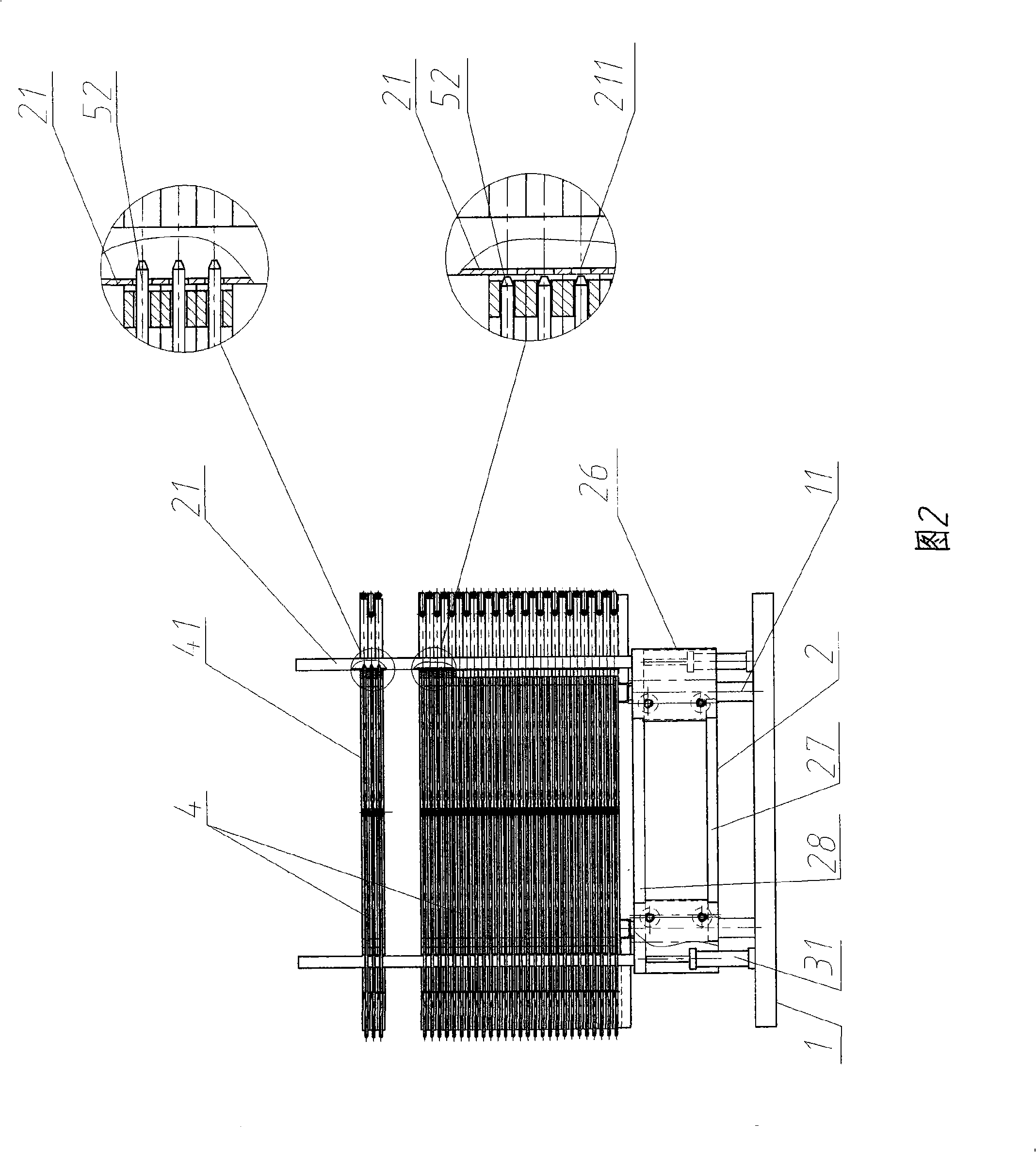

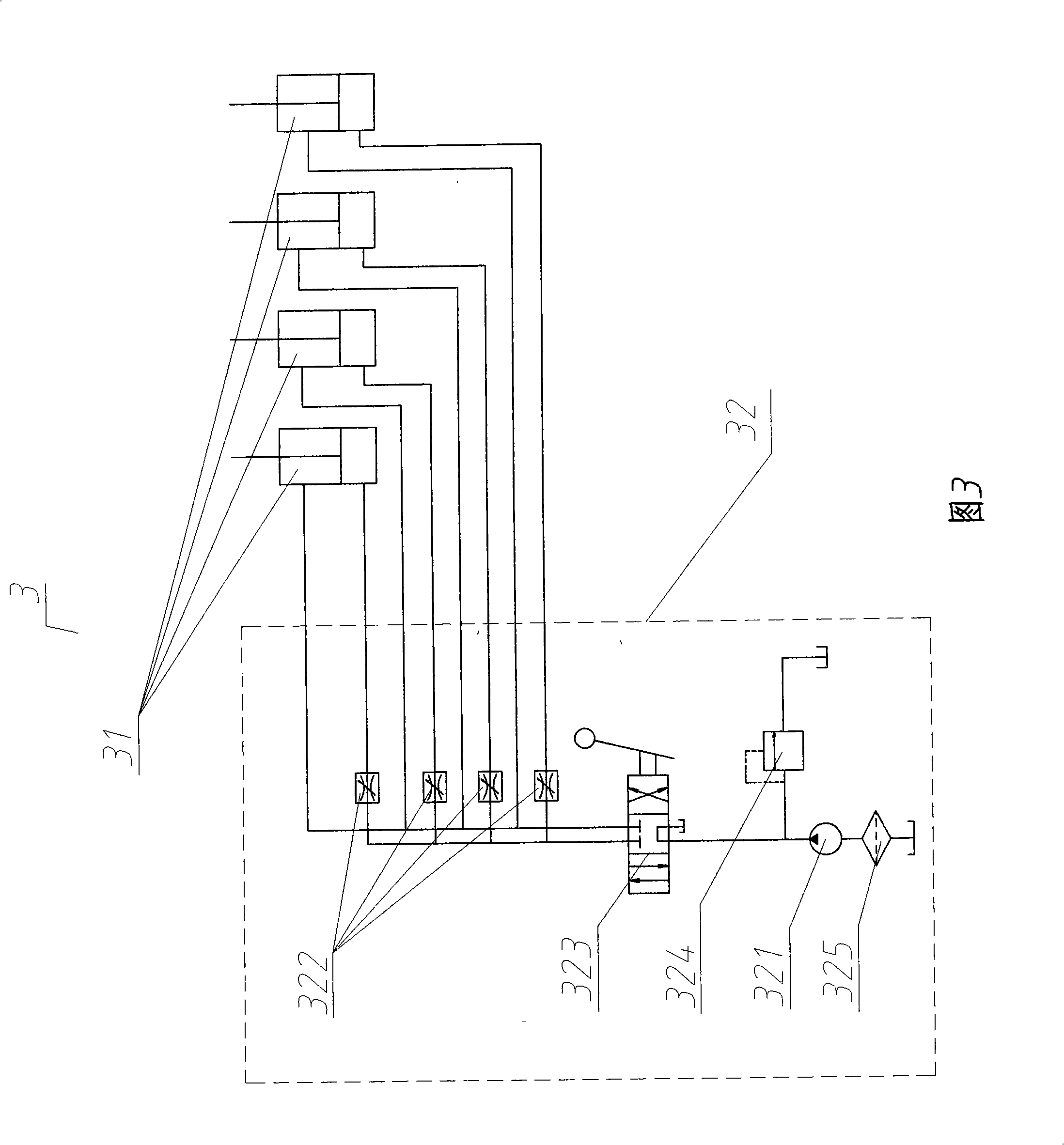

[0027] Such as figure 1 , figure 2 As shown, the vertical multi-layer veneer dryer mainly includes a machine base (1), a lifting frame unit (2), a hydraulic system (3), a heat conduction coil assembly (4) and a positioning pin mechanism (5), There are 4 guide rail shafts fixed on the machine base, the heat conduction coil assembly is placed on the machine base, and the two lifting units stand sideways at both ends of the machine base; the lifting frame unit includes two lifting columns, a lifting frame horizontal Beams, jacking beams, 2 sets of roller assemblies, 2 lifting columns are vertically fixed on the jacking beams, the groove surface of the lifting columns is provided with a row of longitudinal positioning holes, and the roller assemblies include inner plates, outer plates, The roller shaft and the roller, the roller assembly is installed between the jacking beam and the lifting frame beam, and the rollers are inlaid on the inside of two guide rail shafts at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com