Flake pigment and preparation method thereof and cosmetic using the same

A flake and pigment technology, which is applied in the field of flake pigment and its preparation, can solve the problems of high gloss, inability to obtain interference color, inability to obtain matte feeling, etc., and achieve excellent performance, excellent hiding power or matte, The effect of excellent interference color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Suspend 100 g of synthetic α-alumina particles with a particle size of 2-20 μm, an aspect ratio of 10-50 and a diffraction ratio of 1.76-1.77 in 2 L of deionized water, and raise the temperature to about 80° C. 5% chloric acid was added to lower the pH to about 2.0, followed by reflux over 30 minutes. Add 40% TiOCl together 2 and 15% diluted sodium hydroxide solution to adjust the pH to 2.0. With TiOCl 2 With the increase of the added amount, the solution gradually appeared silvery white (120mL), golden (180mL), red (215mL), blue (270mL) and green (320mL). Stop adding TiOCl when the desired color is obtained 2 , and reflux for more than 10 minutes. The acidic solution was filtered, washed three times with deionized water, dried at 110° C. and calcined at 850° C. for 30 minutes to obtain flake pigments.

[0041] According to the X-ray diffraction method, the analysis of the calcined pigment showed the formation of a titanium dioxide layer of anatase structure on the...

Embodiment 2

[0043] Suspend 100 g of synthetic α-alumina particles with a particle size of 2-20 μm, an aspect ratio of 10-50 and a diffraction ratio of 1.76-1.77 in 2 L of deionized water, and raise the temperature to about 80° C. 5% chloric acid was added to lower the pH to about 1.5, followed by reflux over 30 minutes. Add together 30mL 5% SnCl 4 ·5H 2 O solution and 15% diluted NaOH solution were refluxed for 30 minutes while adjusting the pH to 2.0. With SnCl 4 As the amount of addition increased, the solution gradually appeared silvery white (140mL), golden (210mL), red (250mL), blue (315mL) and green (375mL). Stop adding SnCl when desired color is obtained 4 , and reflux for more than 10 minutes. The necessary amount of acidic solution was filtered, washed, dried and calcined as described in Example 1 to obtain flake pigments.

[0044] Analysis of the calcined pigments according to X-ray diffraction showed the formation of a titanium dioxide layer of rutile structure on the sur...

experiment Embodiment 2

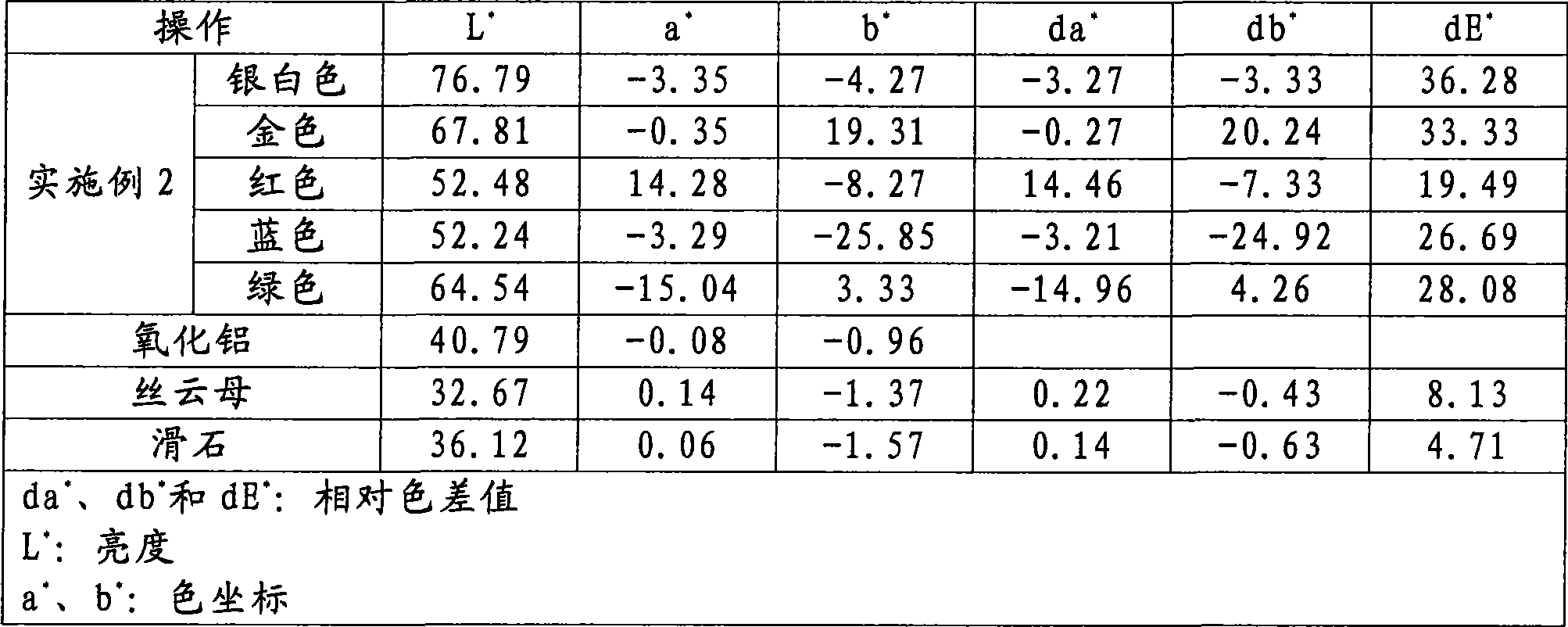

[0056] The color difference of the pigment of Example 2 and sericite and talc, which are generally used in pigment extenders, was measured, and the results are shown in Table 2. Based on the alumina color difference, the relative values of color difference (da * 、db * 、dE * ).

[0057] Measuring Color Difference Using a Colorimeter

[0058] The color difference was measured at 25° using a spectrophotometer CM-512M3 (KONICA MINOLTA SENSING, INC.) by using a squeegee card as described in Test Example 1 for squeegee coating.

[0059] Table 2

[0060]

[0061] As shown in Table 2, alumina, sericite, and talc have low brightness and color coordinates, resulting in difficulty in color development (white powder), and the pigment of Example 2 has a unique interference color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com