Apparatus for transmission and recovery of aerodynamic profile element, and aerodynamic profile element

A technology of aerodynamics and surface elements, applied in wind propulsion elements, transportation and packaging, emission reduction based on propulsion, etc., can solve the problem of difficult control of surface elements, weak strength and direction of wind conditions, flight attitude of surface elements Difficulties and other problems, to achieve the effect of easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

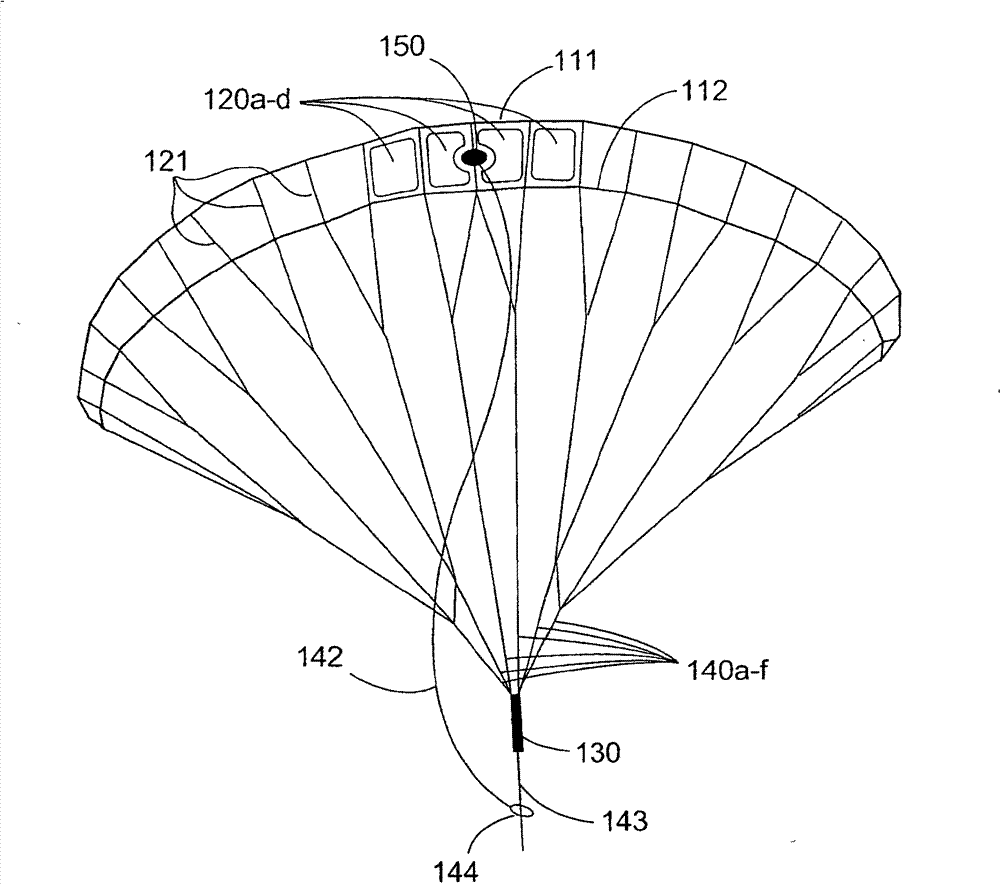

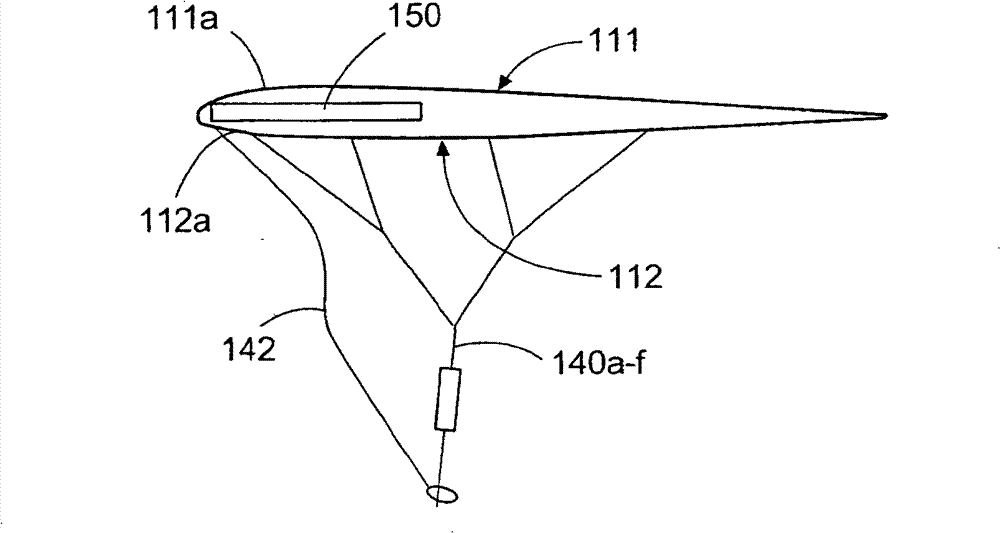

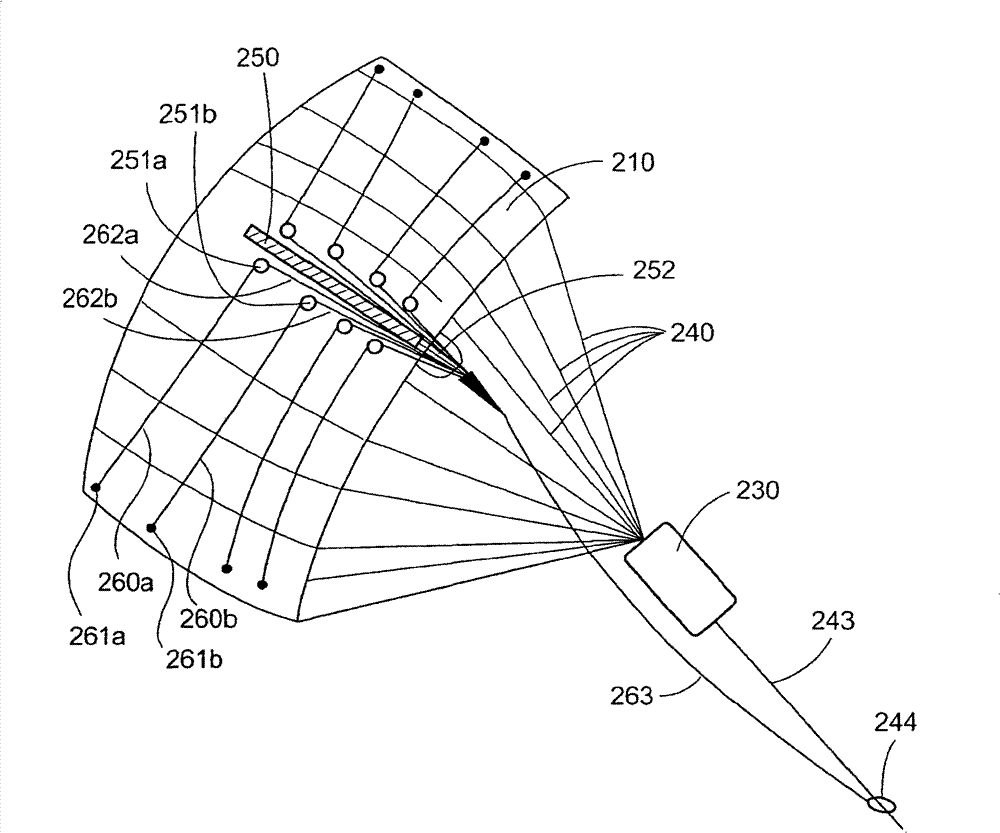

[0072] refer to figure 1 with figure 2 , the aerodynamic profile element in the form of the kite sail 100 according to the invention has a first upper layer 111 and a second lower layer 112 . in accordance with figure 1 Between the front edges 111a and 112a can clearly be seen a plurality of openings 120a-d in the front view of , which are used for the ventilation of the interior cavity between the upper layer 111 and the lower layer 112 . The openings are arranged around the horizontal longitudinal axis of the kite sail. There are no openings in the outer region between the leading edges 111a, 112a.

[0073] The upper and lower layers are connected to each other by means of a plurality of webs 121 . Such a connection consisting of an upper layer, a lower layer and a web is connected to the basket 130 by means of pulling ropes. In this case, a large number of pulling ropes are fastened to the kite, said pulling ropes are grouped together in the direction of the gondola t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com