Locating slip support of large-span space structure

A space structure, large-span technology, applied in the direction of building structure, construction, etc., can solve the problems of limited horizontal displacement of the bearing and weakened bottom plate of the bearing, and achieve the effect of reducing the horizontal thrust, reducing the amount of steel and reliable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

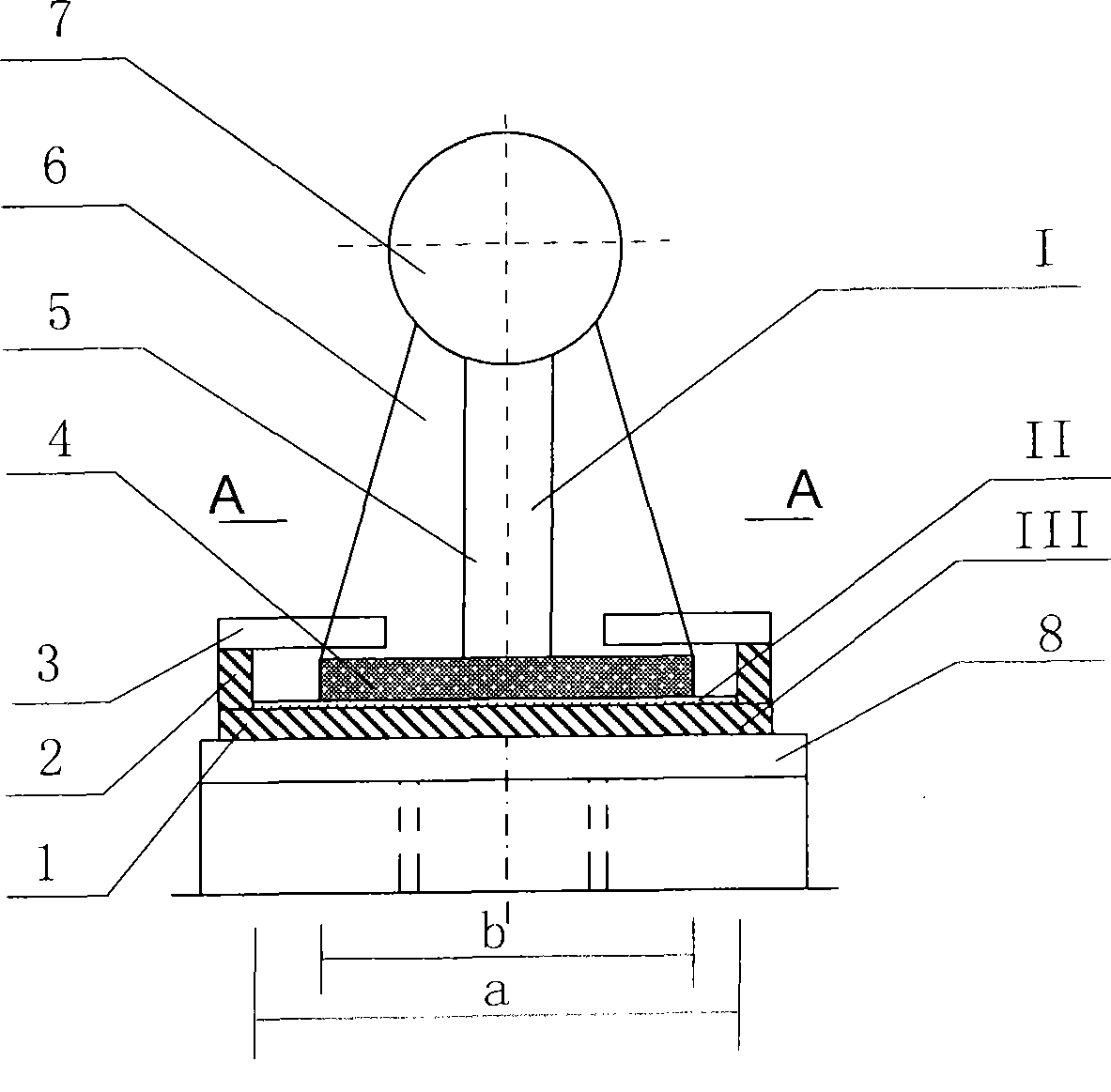

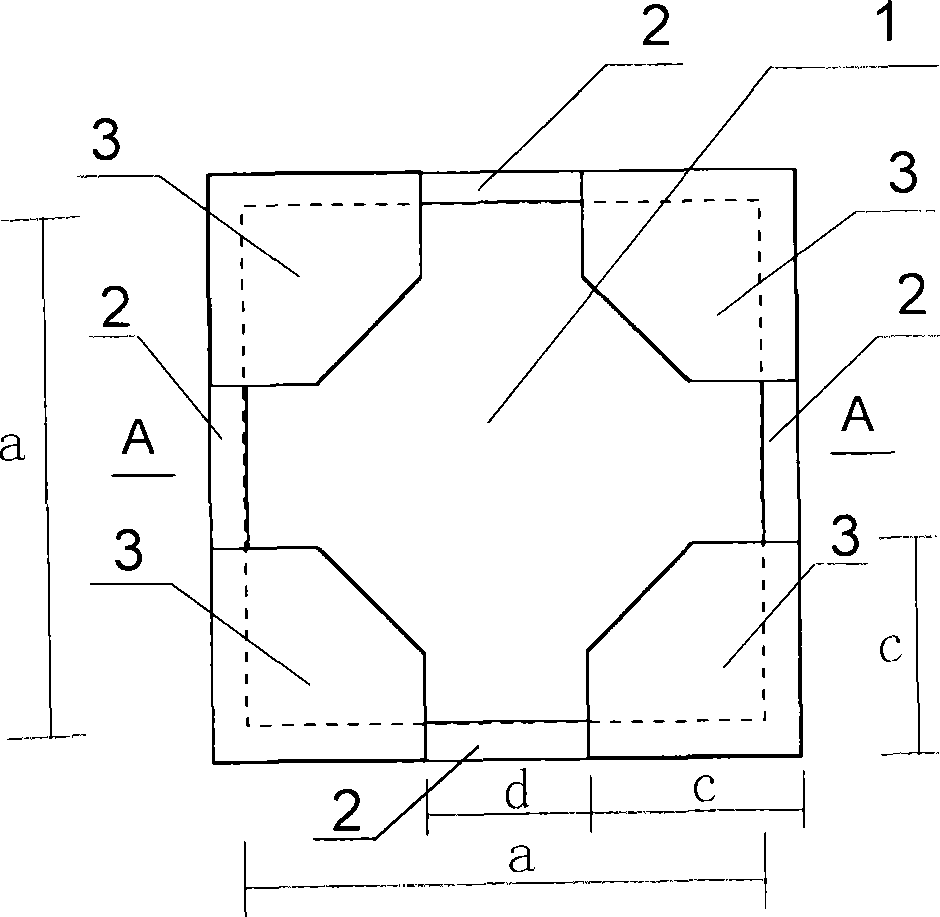

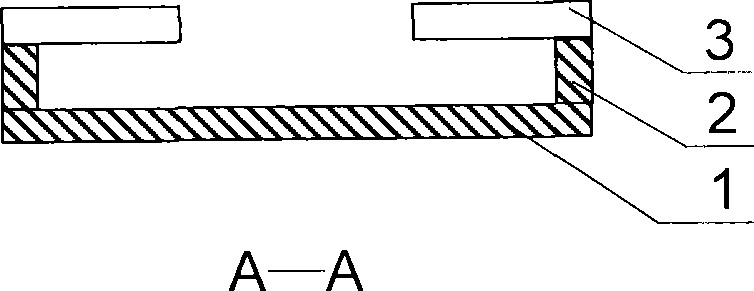

[0018] In conjunction with the accompanying drawings: the whole non-anchor bolt limit slip bearing is composed of the cube limit box III of the lower floor, the increasing slide plate II in the cube limit box and the flat plate support I above the increase slide plate. The cube limit box is connected with the pre-embedded steel plate 8 on the support structure through welds.

[0019] Cube limit box 1 is welded together by a square bottom plate 1 and four limit baffle plates 2 and four small cover plates 3 on the four corners of the periphery.

[0020] In this embodiment, the sliding plate II is a polytetrafluoroethylene plate with a thickness of 8 mm. The polytetrafluoroethylene plate is laid flat in the cube limiting box, and is adhered to the base plate 4 of the cube limiting box by superglue.

[0021] The flat support is provided with a vertical support pipe 5 in the middle of the base plate 4, and four cross-shaped vertical support stiffeners 6 are welded on the periphery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com