Module subgrade case and special module thereof

A subgrade box and box body technology, applied in roads, roads, buildings, etc., can solve problems such as pipeline rupture, difficulty in taking soil, excessive deformation of the road surface, etc., and achieve the effects of improving connection strength, simple construction technology, and avoiding lateral pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

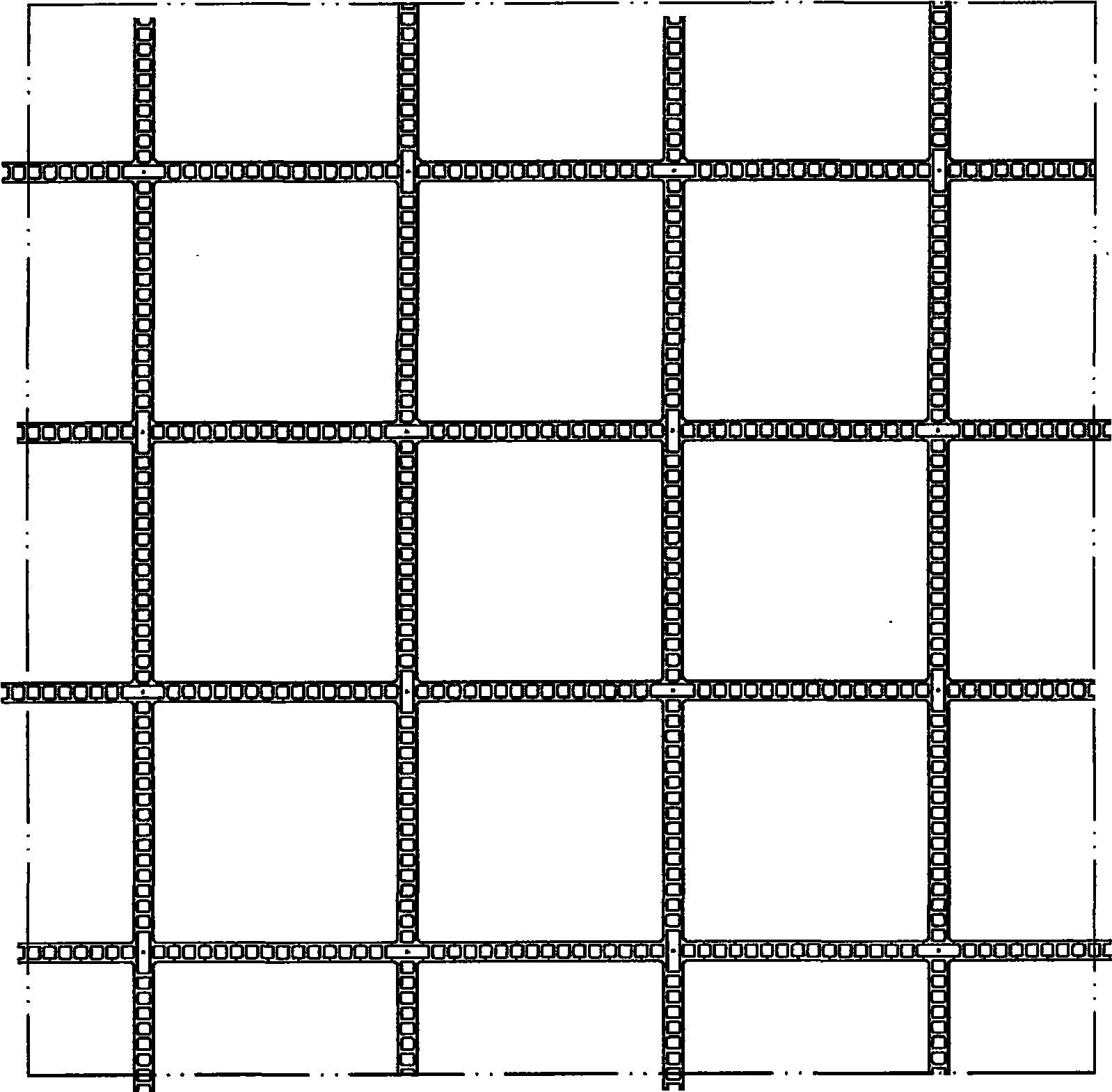

[0036] In the excavated roadbed or bridge foundation, according to the height of the roadbed or bridge foundation, use modules to construct a square grid box frame of the required height, and attach figure 1 It is a top view of the aforementioned square grid-like box frame. During construction, the modules of adjacent layers are placed in such a way that they form a seam structure, that is, the joints between adjacent modules of any layer are not at the same level as the joints between adjacent modules of the adjacent upper or lower layers. in a straight line.

[0037] attached Figure 13 A top view showing the connection modules and their connection status for building a square grid-like box frame, with Figure 13 The middle solid line shows the connection module, and the dotted line shows the modules connected with the connection module.

[0038] Concrete is poured inside the completed square grid-shaped box frame, and after the concrete is solidified, the modular roadbed...

Embodiment 2

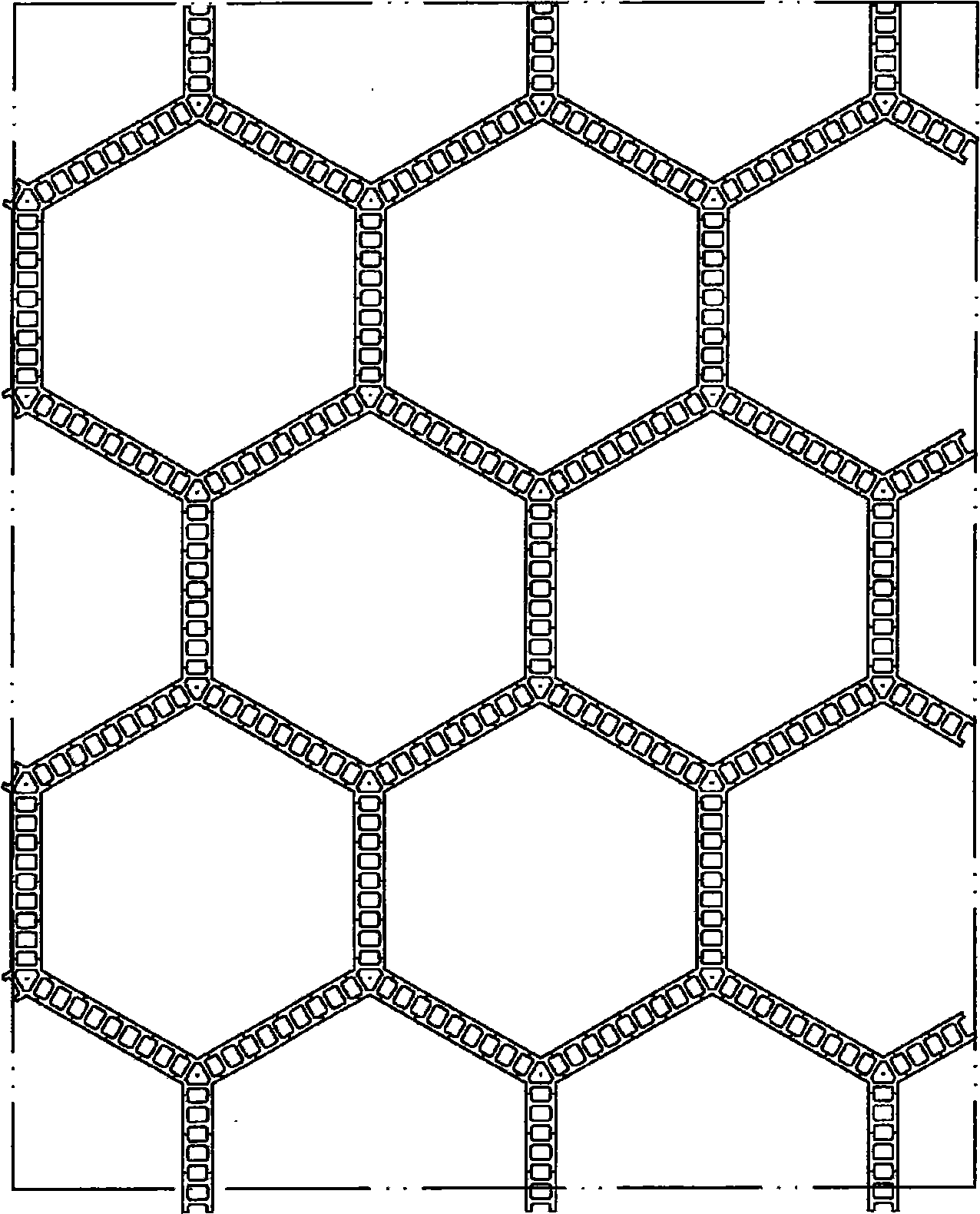

[0040] In the excavated roadbed or bridge foundation, according to the height of the roadbed or bridge foundation, use modules to construct a regular hexagonal grid-shaped box frame of the required height, and attach figure 2 It is a top view of the aforementioned regular hexagonal grid box frame. During construction, the modules of adjacent layers are placed in such a way that they form a seam structure, that is, the joints between adjacent modules of any layer are not at the same level as the joints between adjacent modules of the adjacent upper or lower layers. in a straight line.

[0041] When constructing a regular hexagonal grid-like box frame, additional Figure 14 , attached Figure 15 or attach Figure 16 Connection module shown.

[0042] attached Figure 14 A top view showing the first connection module and its connection status for constructing a regular hexagonal grid box frame, with Figure 14The middle solid line shows the connection module, and the dotted...

Embodiment 3

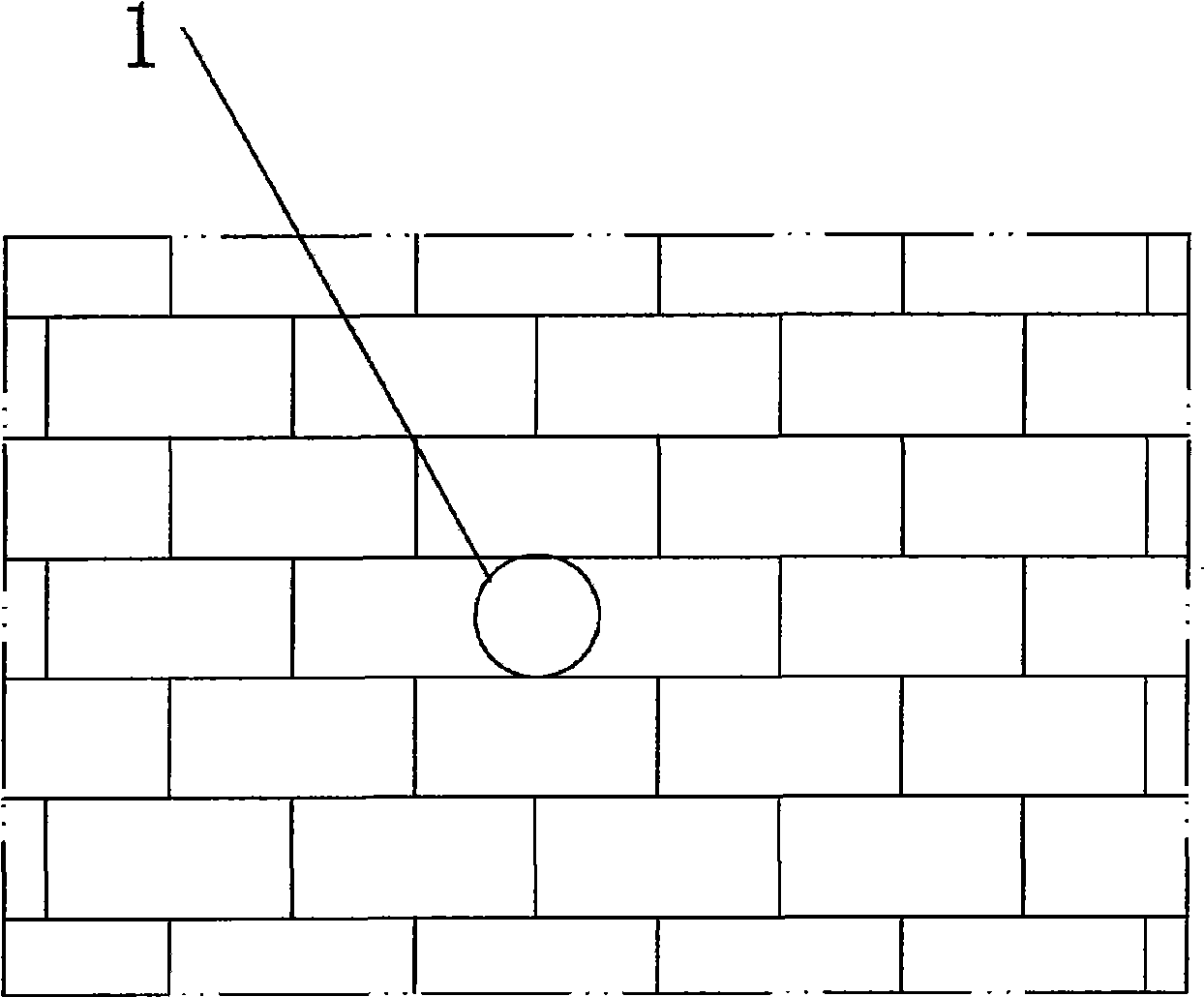

[0047] When constructing a box frame with a square or regular hexagonal grid, at the height layer where the pipeline needs to be laid, follow the direction of the pipeline so that the two adjacent modules on the corresponding layer do not touch, and leave a gap according to the outer diameter of the pipeline , that is, the pipeline hole 1 is formed. attached image 3 is a partial plan view of the box frame showing the cross-section of the conduit hole 1. Before placing the upper module, place the pipeline in the pipeline hole 1.

[0048] Concrete is poured inside the constructed square or regular hexagonal grid box frame, and after the concrete is solidified, the modular subgrade box with pipeline holes of the present invention is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com