Simulation reaction method for producing denatured rice starch with high degree of substitution by using wet-process

A technology of modified rice starch and high degree of substitution is applied in the field of wet production of modified rice starch with high degree of substitution, which can solve the problems of large amount of addition, high cost, low cost, etc., so as to improve the degree of substitution, reduce production costs, and reduce product cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

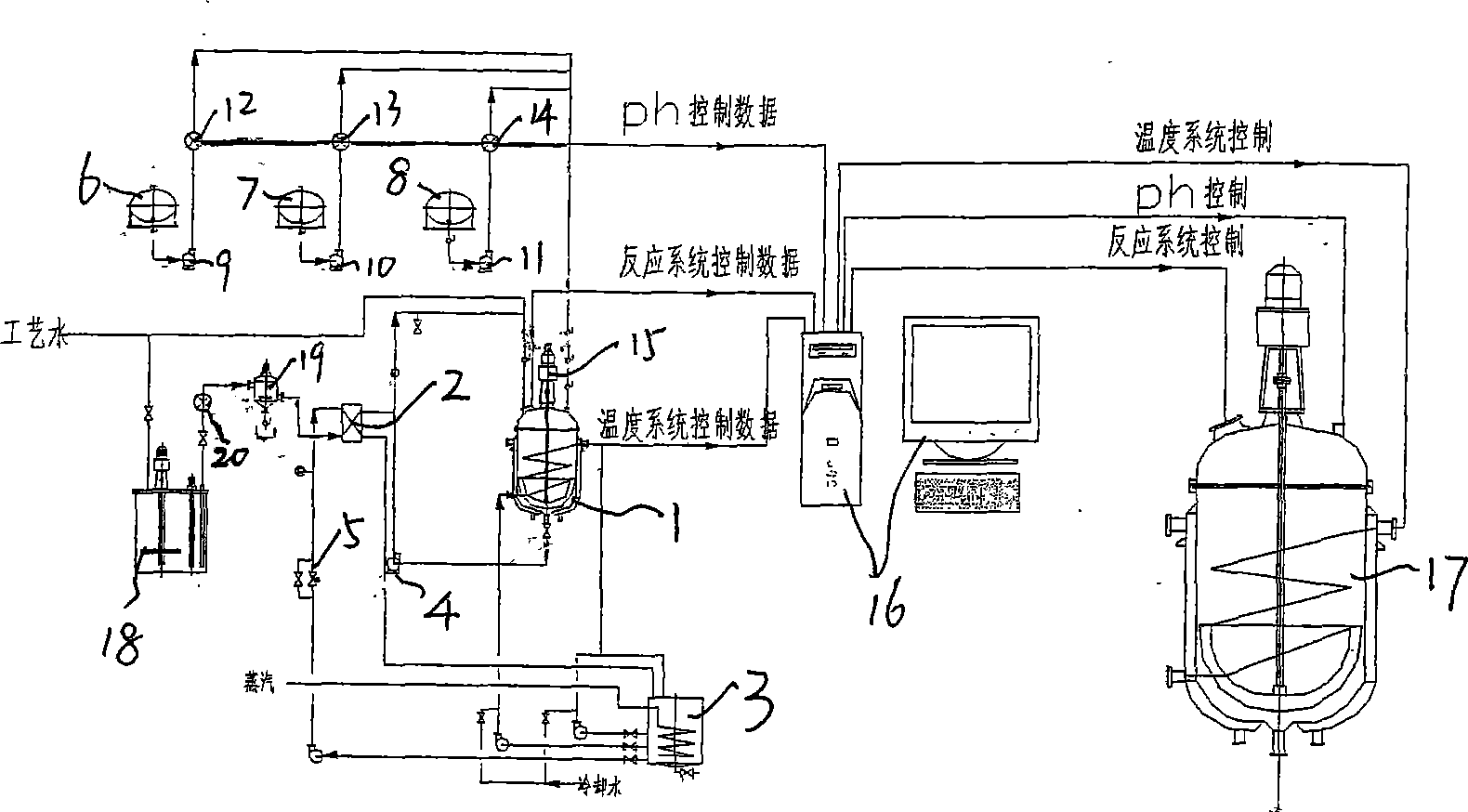

[0018] A simulated reaction method for wet production of highly substituted modified rice starch, using a simulated reactor for simulated reaction, the simulated reactor consists of a 50-liter small reactor, and a small temperature automatic heat exchange system matched with the small reactor , a small PH value control system, a mixer with a small reactor and a computer. Concrete composition: including a 50 liter small reaction kettle 1, small temperature automatic heat exchange system (including heat exchanger 2, hot water tank 3, slurry circulation pump 4, regulating valve 5, etc.), small PH value control system (including reagent Storage tank 6, lye storage tank 7, acid storage tank 8, reagent pump 9, lye pump 10, acid pump 11, flow meters 12, 13, 14, etc.), a mixer 15 and a small reaction kettle 1 supporting connected, the computer data processing control system 16 accepts temperature, reaction time, reaction reagent and pH value feedback information, and sends control ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com