Preparation method of nano feed additive

A feed additive and nano-technology, applied in the preparation of nano-feed additives, in the field of nano-feed additives, can solve the problems of complex NMDA processing technology and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

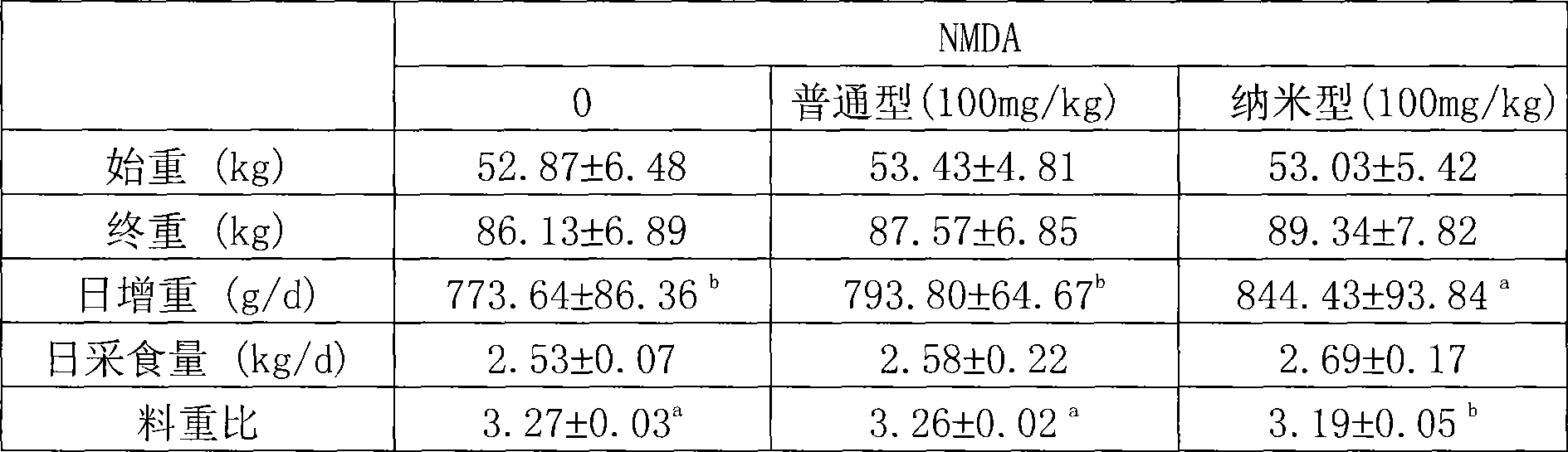

Examples

Embodiment 1

[0013] 1) Separation and purification of montmorillonite minerals: put 8.0L of distilled water in the container, put 400g of montmorillonite and 20g of sodium chloride in the container, stir at high speed to make a suspension slurry with a concentration of 5%, age for 10 hours, and wash with water 6 times;

[0014] 2) Add 4.0g of NMDA to the above pulp under high-speed stirring, continue stirring for 6 hours, the reaction temperature is 80°C, then aging at 30°C for 72 hours, washing with water 10 times, and filtering;

[0015] 3) The filter residue was vacuum-dried at 40° C. for 6 hours, and then crushed by dry method with a jet mill.

Embodiment 2

[0017] 1) Separation and purification of montmorillonite minerals: put 6.4L of distilled water in the container, put 320g of montmorillonite and 32g of sodium chloride in the container, stir at a high speed, make a suspension slurry with a concentration of 5%, age for 10 hours, wash with water 10 times;

[0018] 2) Add 64.0 g of NMDA to the above slurry under high-speed stirring, continue stirring for 10 hours, the reaction temperature is 60°C, then aging at 60°C for 36 hours, washing with water 6 times, and filtering;

[0019] 3) The filter residue was vacuum-dried at 60° C. for 3 hours, and dry-milled with a jet mill.

Embodiment 3

[0021] 1) Separation and purification of montmorillonite minerals: put 5L of distilled water in the container, put 1000g of montmorillonite and 100g of sodium chloride in the container, stir at high speed to make a suspension slurry with a concentration of 10%, aging for 12 hours, washing with water for 8 Second-rate;

[0022] 2) Add 50g of NMDA to the above pulp under high-speed stirring, continue to stir for 10 hours, the reaction temperature is 50°C, then age at 40°C for 48 hours, wash 8 times with water, and filter;

[0023] 3) The filter residue was vacuum-dried at 50° C. for 4 hours, and dry-milled with a jet mill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com