Mine ventilation counter flow oxidation thermo-electric generation system

A technology of thermoelectric power generation and countercurrent oxidation, which is applied in the directions of generators/motors, electrical components, etc., can solve the problems of small income, expensive core equipment, and has not been widely promoted and applied, and achieves the effect of preventing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

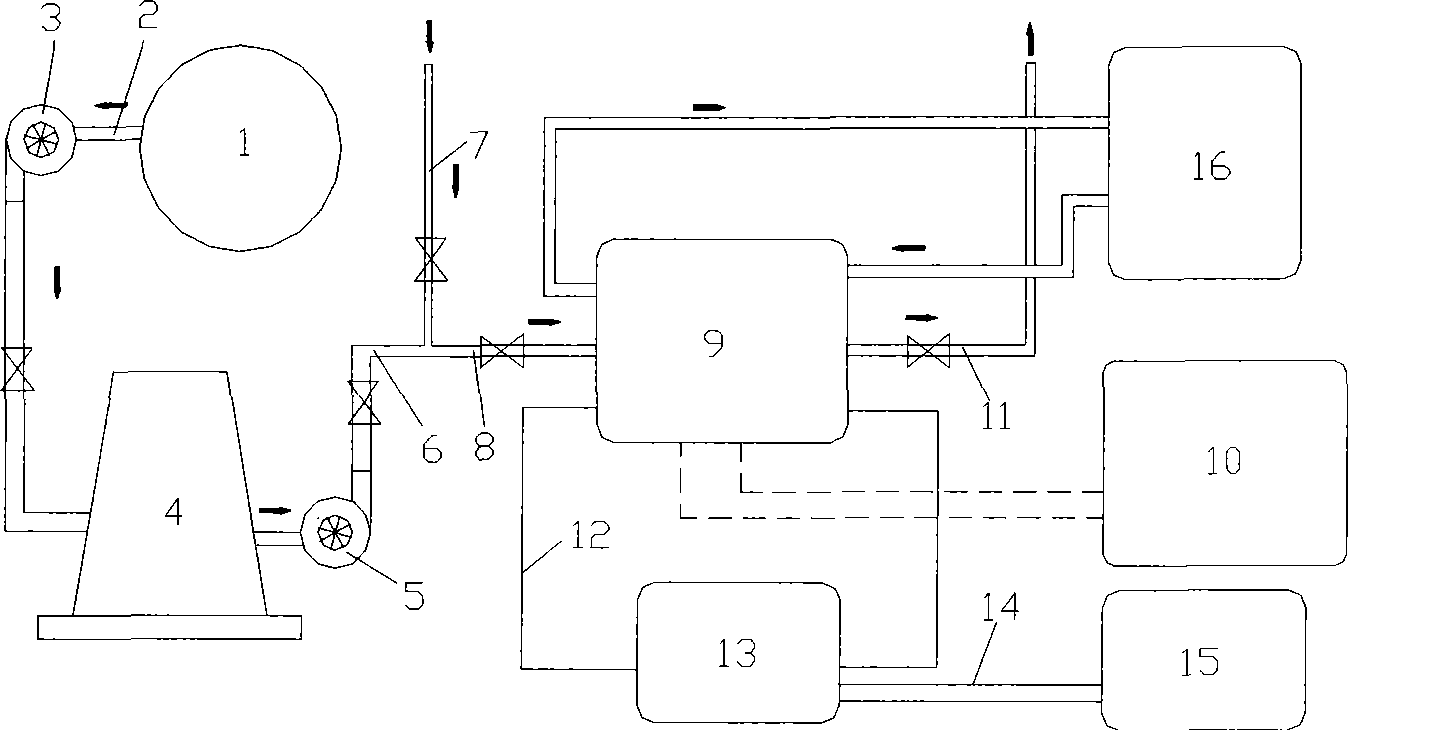

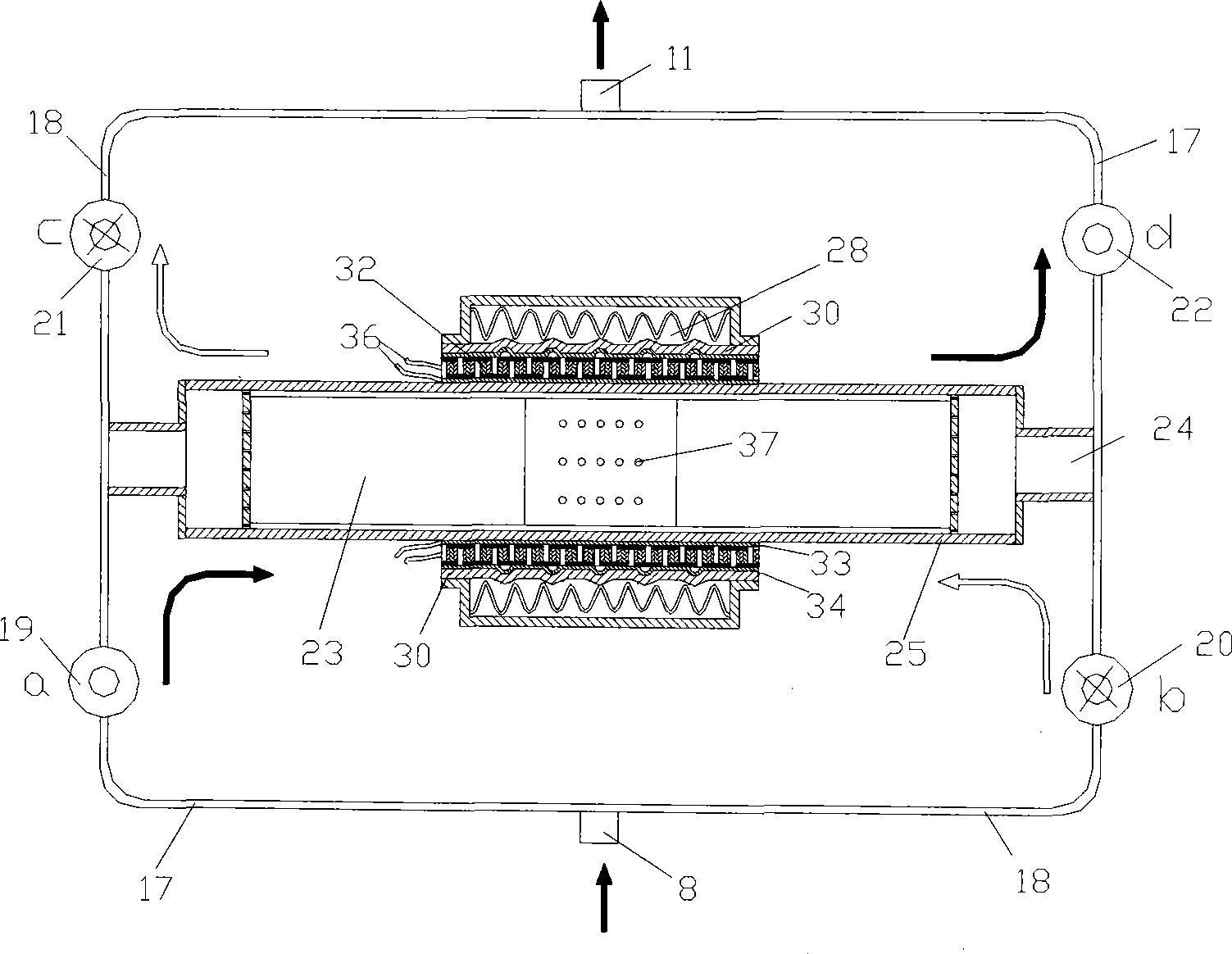

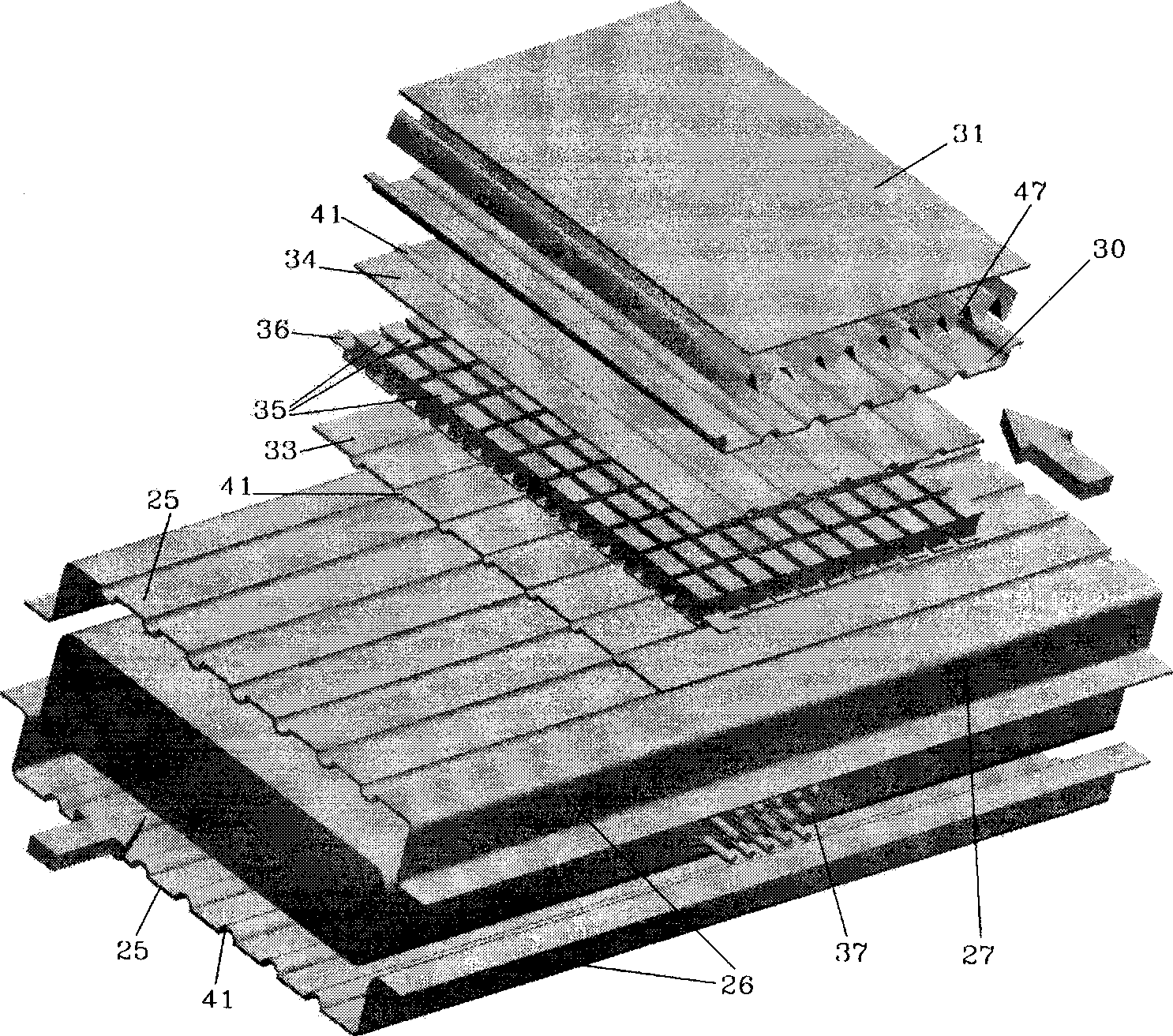

[0019] like Figure 1-5 As shown, the mine exhaust air countercurrent oxidation temperature difference power generation system of the present invention consists of a mine 1, a pipeline 2, an induced draft fan 3, a gas purification storage device 4, a blower 5, a mine exhaust air intake pipe 6, an air intake pipe 7, a mixing Gas inlet pipeline 8, countercurrent oxidation thermoelectric power generation device 9, control system 10, exhaust pipeline 11, thermoelectric generator electrode wire 12, DC-DC converter 13, DC current output wire 14, electrical equipment 15 and hot water users Composed of 16, the outlet of mine 1 is connected to the inlet of induced draft fan 3, the outlet of induced draft fan 3 is connected to the inlet of gas purification storage device 4, the outlet of gas purification storage device 4 is connected to the inlet of blower 5, and the outlet of blower 5 is connected to mine exhaust air intake pipe 6 , the mine exhaust air inlet pipe 6 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com