Double refraction measuring method, apparatus and program

A measurement method and birefringence technology, applied in the direction of testing optical properties, etc., can solve the problems of high price of photoelastic modulators, and photoelastic modulators are easily affected by temperature, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

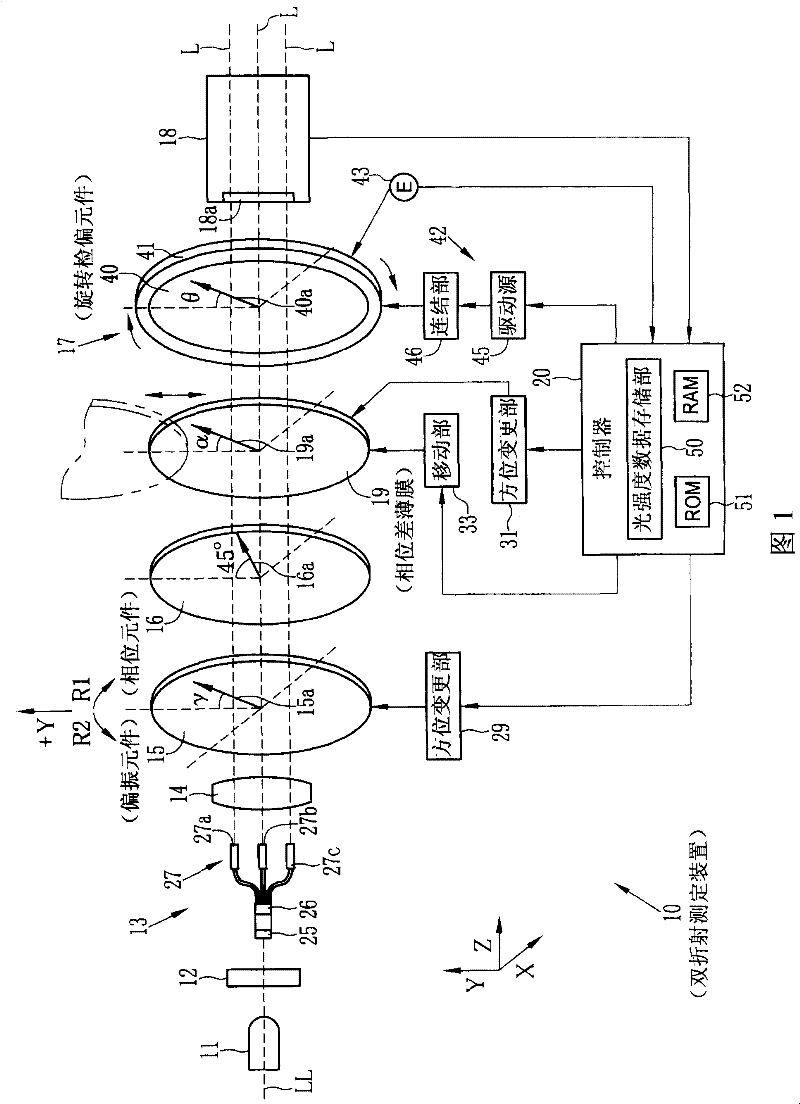

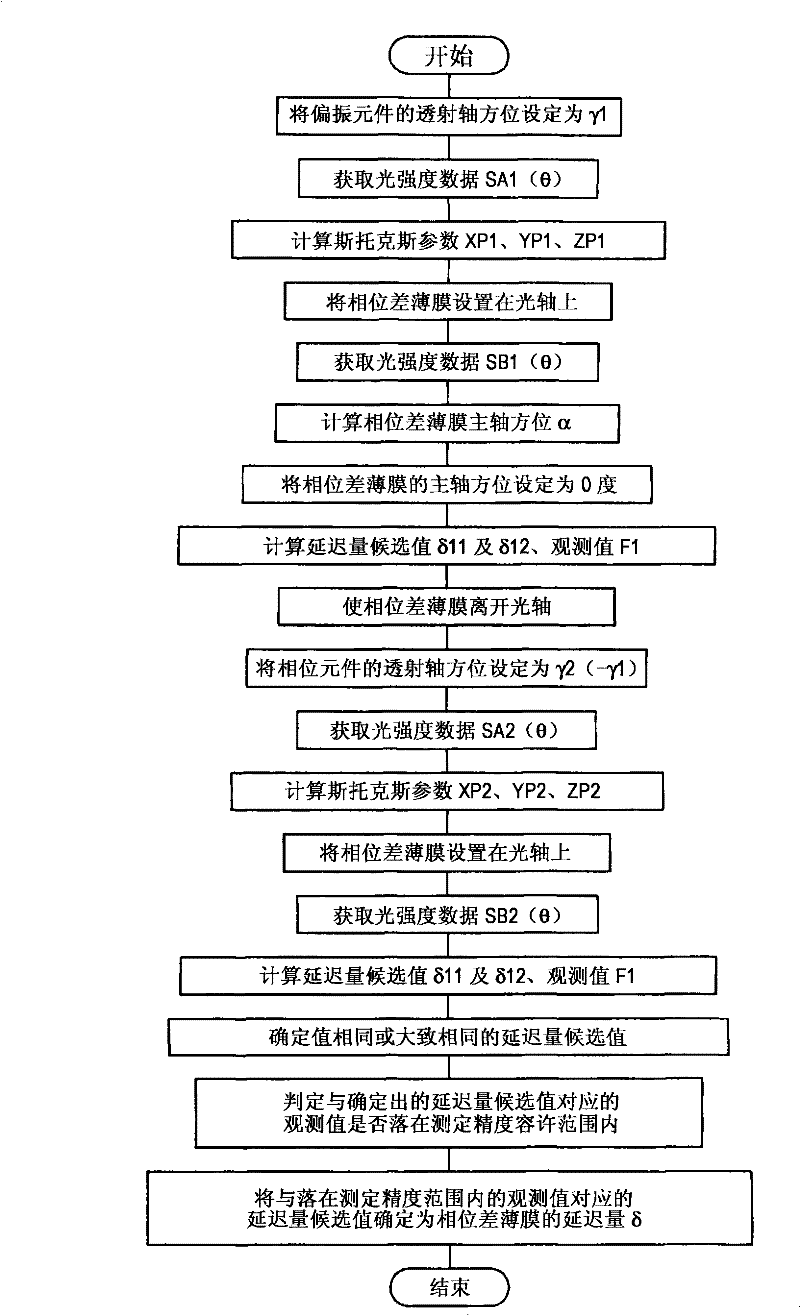

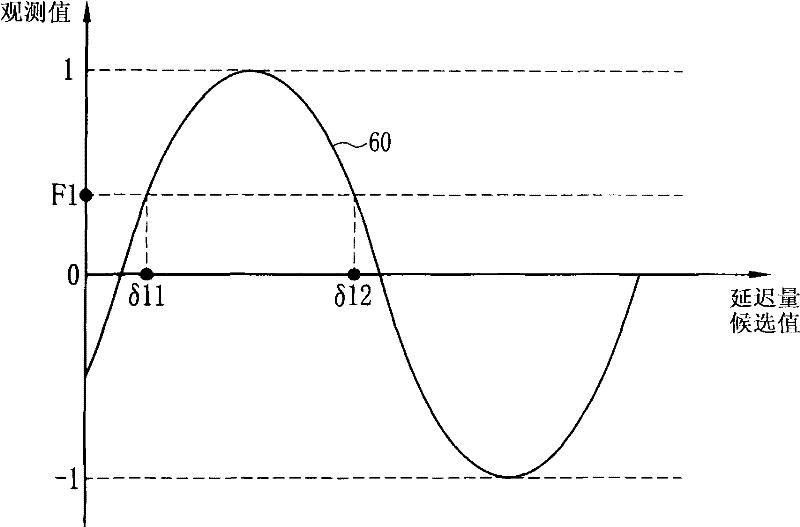

Method used

Image

Examples

Embodiment

[0134] In the examples, first, the birefringent phase difference of the BSC compensation element as the measurement object was measured. The BSC compensation element is a phase element whose birefringence phase difference changes continuously corresponding to the feeding amount of the micrometer screw. In the first verification, in order to verify that the birefringent phase difference can be measured with high precision within the range of 0° to 360°, the phase difference of the BSC was varied from 0° to 360°, and the absolute value of the measurement and 100 measurements were confirmed. repeatability accuracy. The higher the linearity of the measured birefringence phase difference with respect to the feed amount of the microscrew, the higher the measurement accuracy can be judged. Additionally, if Figure 7 As shown, 3σ (σ is the standard deviation) is taken as the repeatability. This measurement was carried out under the conditions of a measurement wavelength of 590 nm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com