Substitution control method for air conditioner fault sensor

A fault sensor and alternative control technology, applied in heating and ventilation control systems, heating methods, space heating and ventilation, etc., can solve problems such as the impact of users' daily use, and achieve the effect of avoiding inconvenience and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

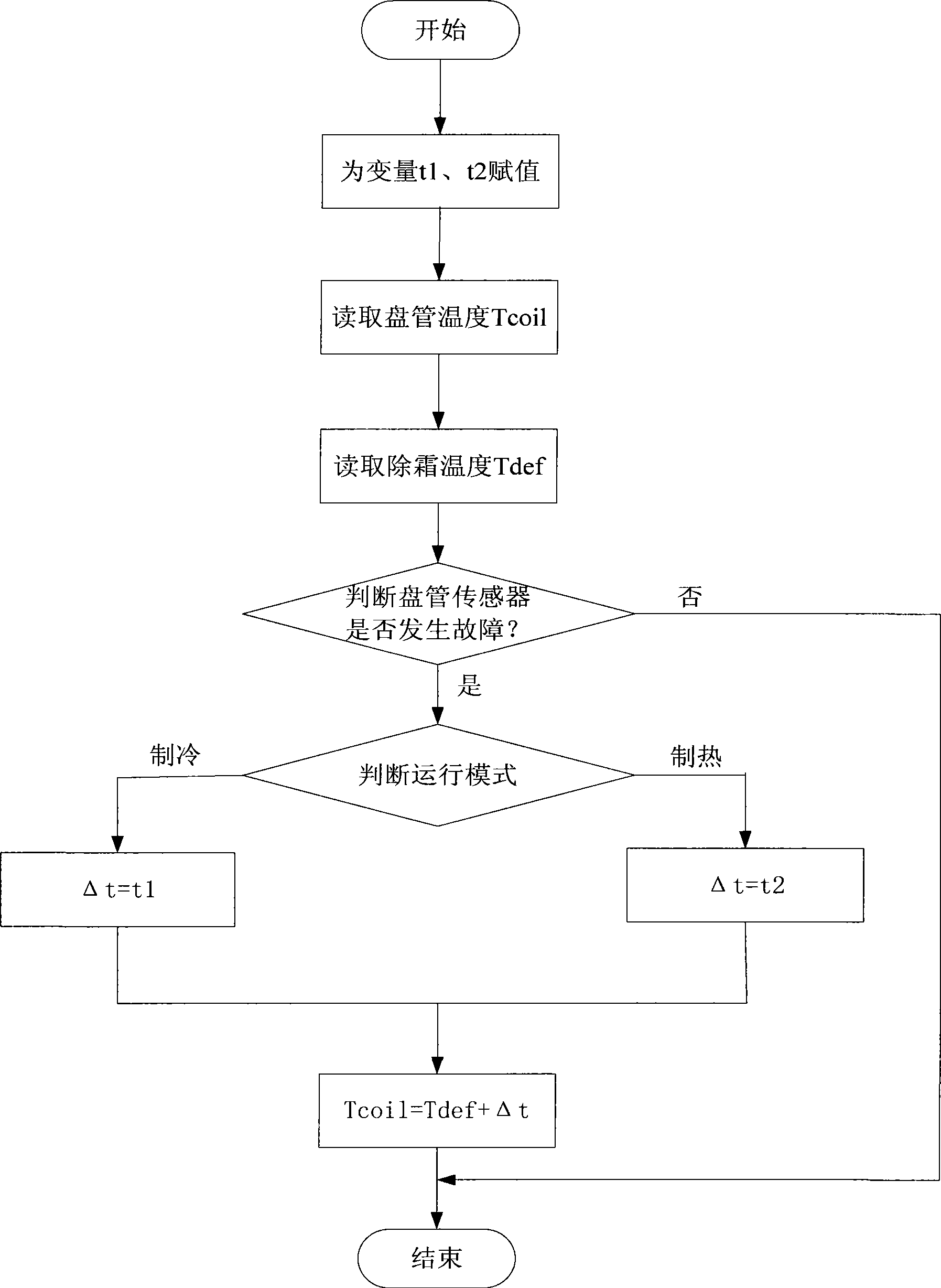

[0024] Embodiment 1, this embodiment discloses an alternative control method when the coil temperature sensor fails, that is, when the condenser coil temperature sensor fails, read the detection value of the defrosting temperature sensor set on the condenser , recorded as Tdef; the detection value Tdef is corrected, that is, after adding a correction value Δt, to replace the detection value of the coil temperature sensor, recorded as Tcoil; and then Tcoil and Tdef are substituted into the main control program to participate in the control calculation, so that Realize the continuous operation of the main control program, so that the whole unit can achieve the purpose of non-stop operation while alarming and waiting for repair, so as to facilitate the use of users.

[0025] Since the detection values output by the coil temperature sensor and the defrosting temperature sensor are generally analog signals, after being received by the analog-to-digital conversion module inside the...

Embodiment 2

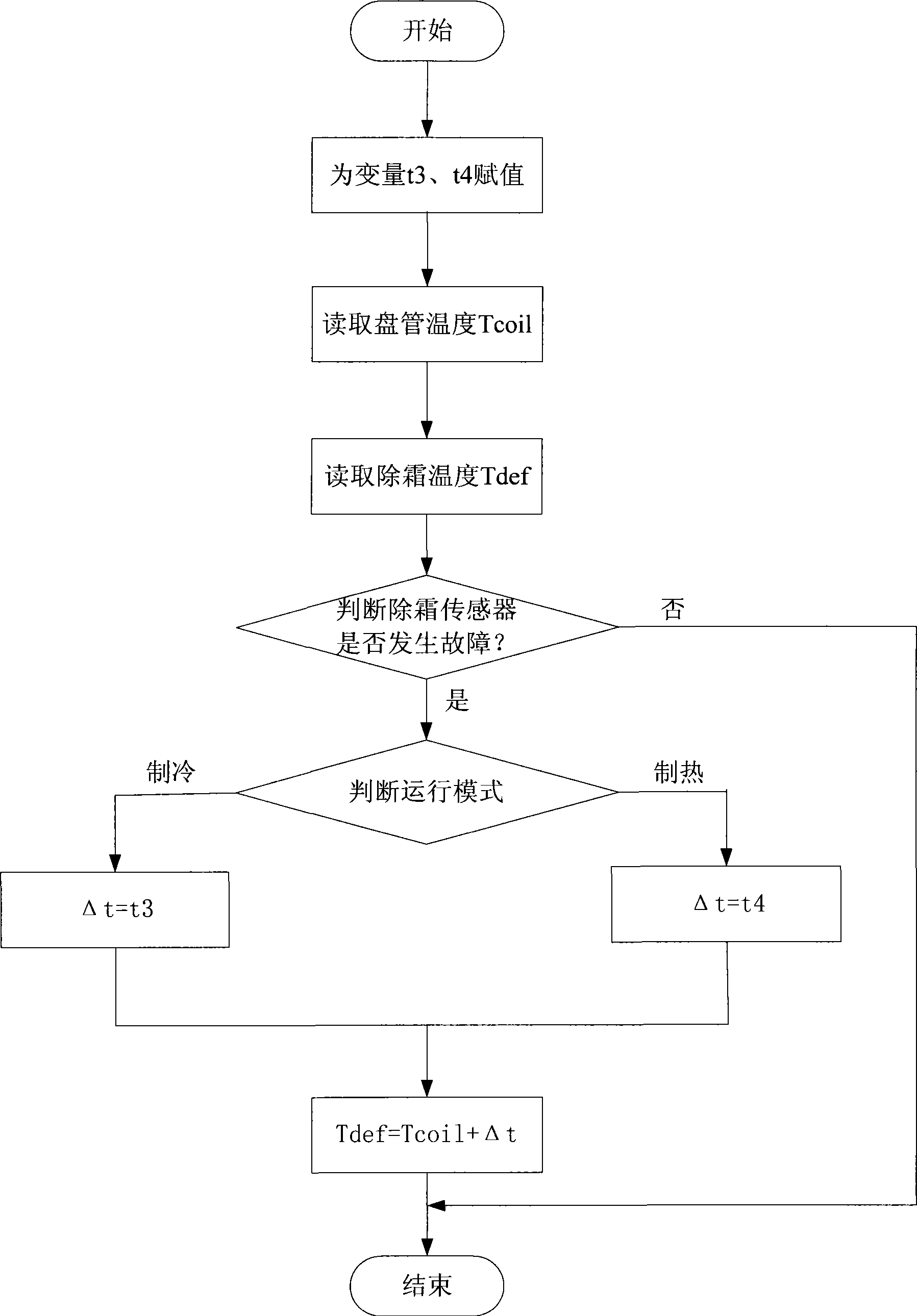

[0040] Embodiment 2, this embodiment discloses an alternative control method when the defrosting temperature sensor fails, that is, when the defrosting temperature sensor of the condenser fails, read the detection value of the coil temperature sensor set on the condenser , denoted as Tcoil; the detection value Tcoil is corrected, that is, after adding a correction value Δt, to replace the detection value of the defrosting temperature sensor, denoted as Tdef; then Tcoil and Tdef are substituted into the main control program to participate in the control calculation, In this way, the main control program can be continuously operated, so that the whole unit can achieve the purpose of continuous operation without stopping the machine while alarming and waiting for repair.

[0041] As in Embodiment 1, the detection values Tcoil and Tdef may refer to specific temperature values corresponding to the analog voltage signals output by the coil temperature sensor and the defrosting te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com