Method for producing anticorrosive oil composition

A production method and composition technology, applied in lubricating compositions, petroleum industry, base materials, etc., can solve the problems of long production time of anti-rust oil composition, easy excessive oxidation of oil products, affecting anti-rust effect, etc., and achieve shortening Production time, shortened production time, and the effect of preventing excessive oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

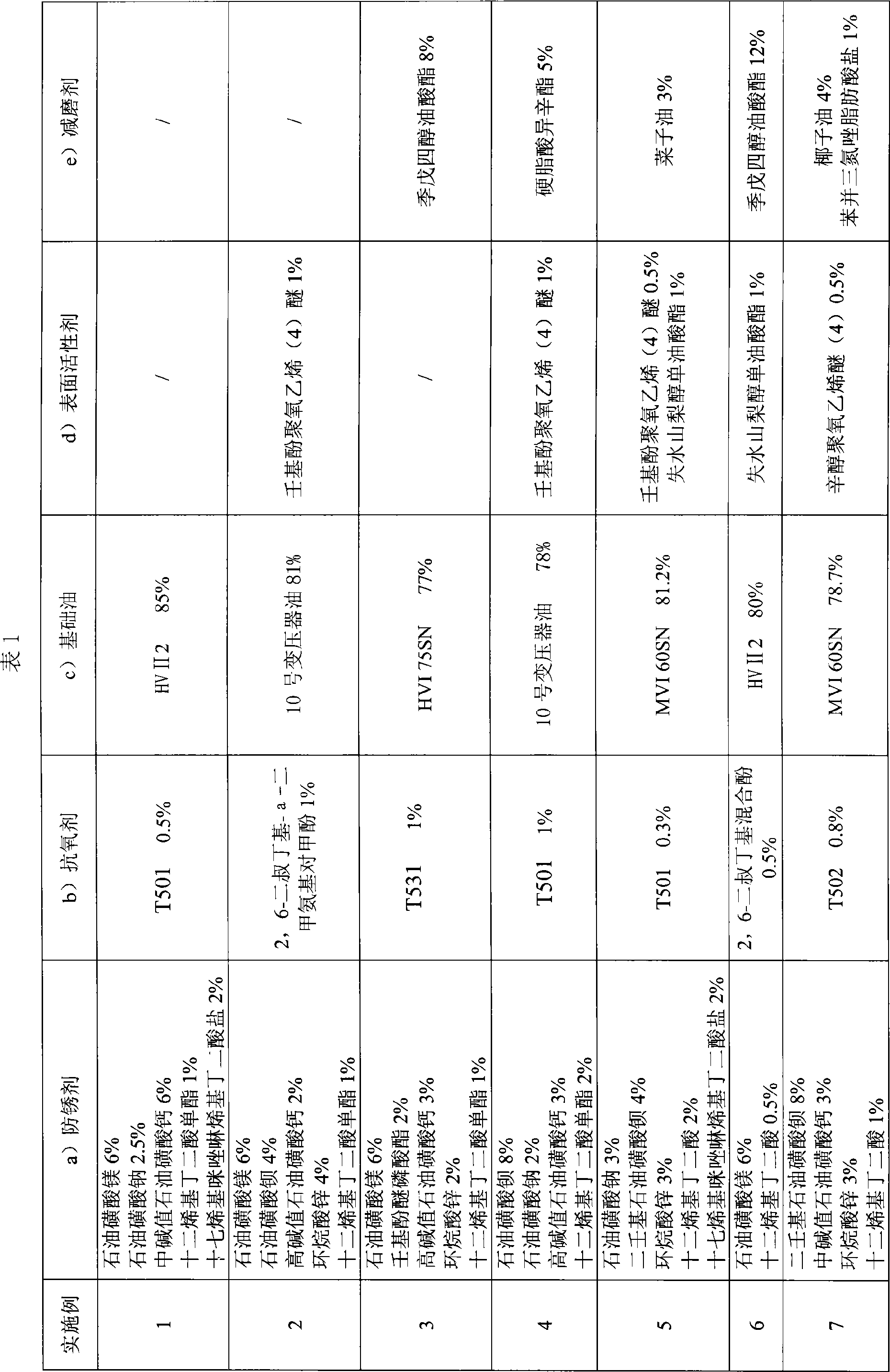

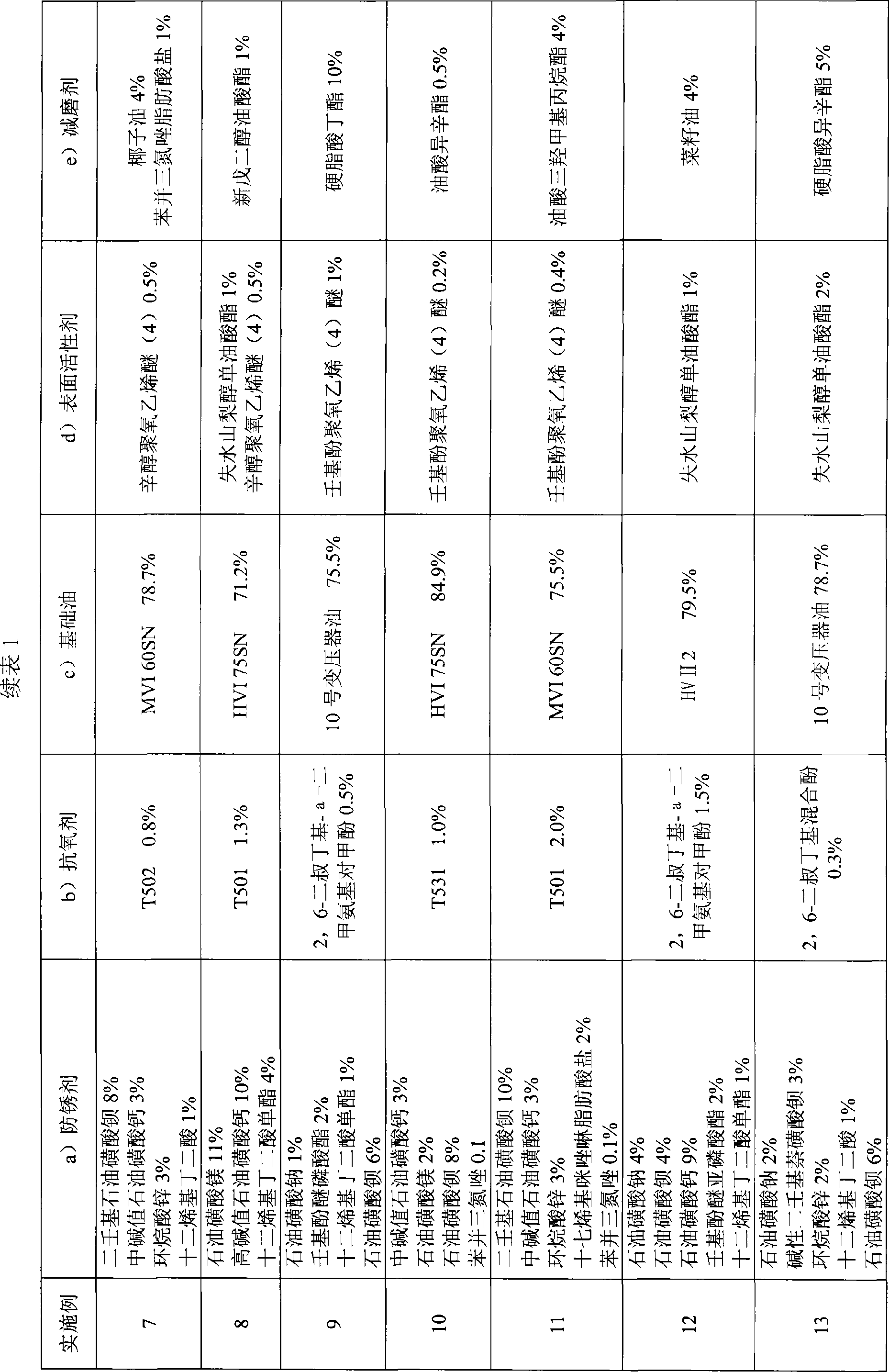

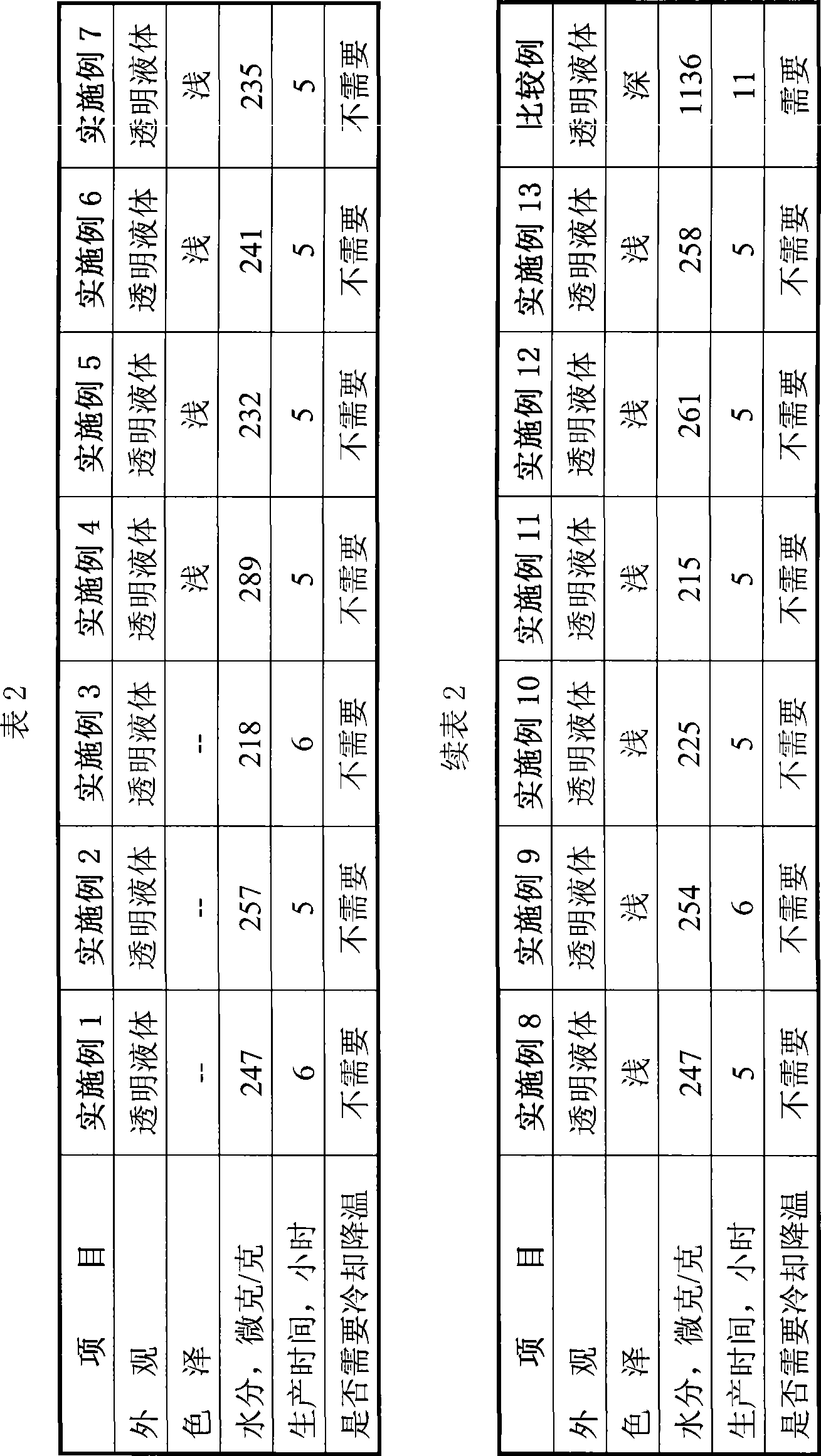

Embodiment 1

[0022] Add 500 kg of twice-hydrogenated mineral oil HV II2 (produced by Sinopec Shanghai Gaoqiao Branch) into the blending kettle and heat to 60°C; add magnesium petroleum sulfonate, sodium petroleum sulfonate, and calcium petroleum sulfonate with medium alkalinity , dodecenyl succinate monoester, heptadecenyl imidazolidinyl succinate, 2,6-di-tert-butyl p-cresol, continue heating to 110°C, and stir at constant temperature for 4 hours. Then add 350 kg of twice hydrogenated mineral oil HV II2, stir evenly, and circulate and filter with a suction filter until the oil temperature drops to 75°C for canning. Each component and its weight percentage are shown in Table 1, and the product properties are shown in Table 2.

Embodiment 2

[0024] Add 550 kg of No. 10 transformer oil into the blending kettle and heat it to 65°C; add magnesium petroleum sulfonate, sodium petroleum sulfonate, calcium petroleum sulfonate with high alkali value, zinc naphthenate, dodecenylsuccinic acid mono Esters, 2,6-di-tert-butyl-a-dimethylamino-p-cresol, and nonylphenol polyoxyethylene (4) ether were heated to 115°C and stirred at constant temperature for 2.5 hours. Then add 300 kg of No. 10 transformer oil, stir evenly, and circulate and filter with a suction filter until the oil temperature drops to 75°C for canning. Each component and its weight percentage are shown in Table 1, and the product properties are shown in Table 2.

Embodiment 3

[0026]Add 600kg of HVI75SN into the blending kettle and heat to 80°C; add petroleum magnesium sulfonate, nonylphenol ether phosphate, high alkali value calcium petroleum sulfonate, zinc naphthenate, dodecenyl succinate monoester , N-amino-a-naphthylamine, pentaerythritol oleate, continue heating to 120°C, and stir at constant temperature for 2 hours. Then add 240 kg of base oil, stir evenly, and circulate and filter with a suction filter until the oil temperature drops to 75°C for canning. Each component and its weight percentage are shown in Table 1, and the product properties are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com